Vivado Design Suite User

Guide

Using Constraints

UG903 (v2022.1) June 1, 2022

Xilinx is creating an environment where employees, customers, and

partners feel welcome and included. To that end, we’re removing non-

inclusive language from our products and related collateral. We’ve

launched an internal initiative to remove language that could exclude

people or reinforce historical biases, including terms embedded in our

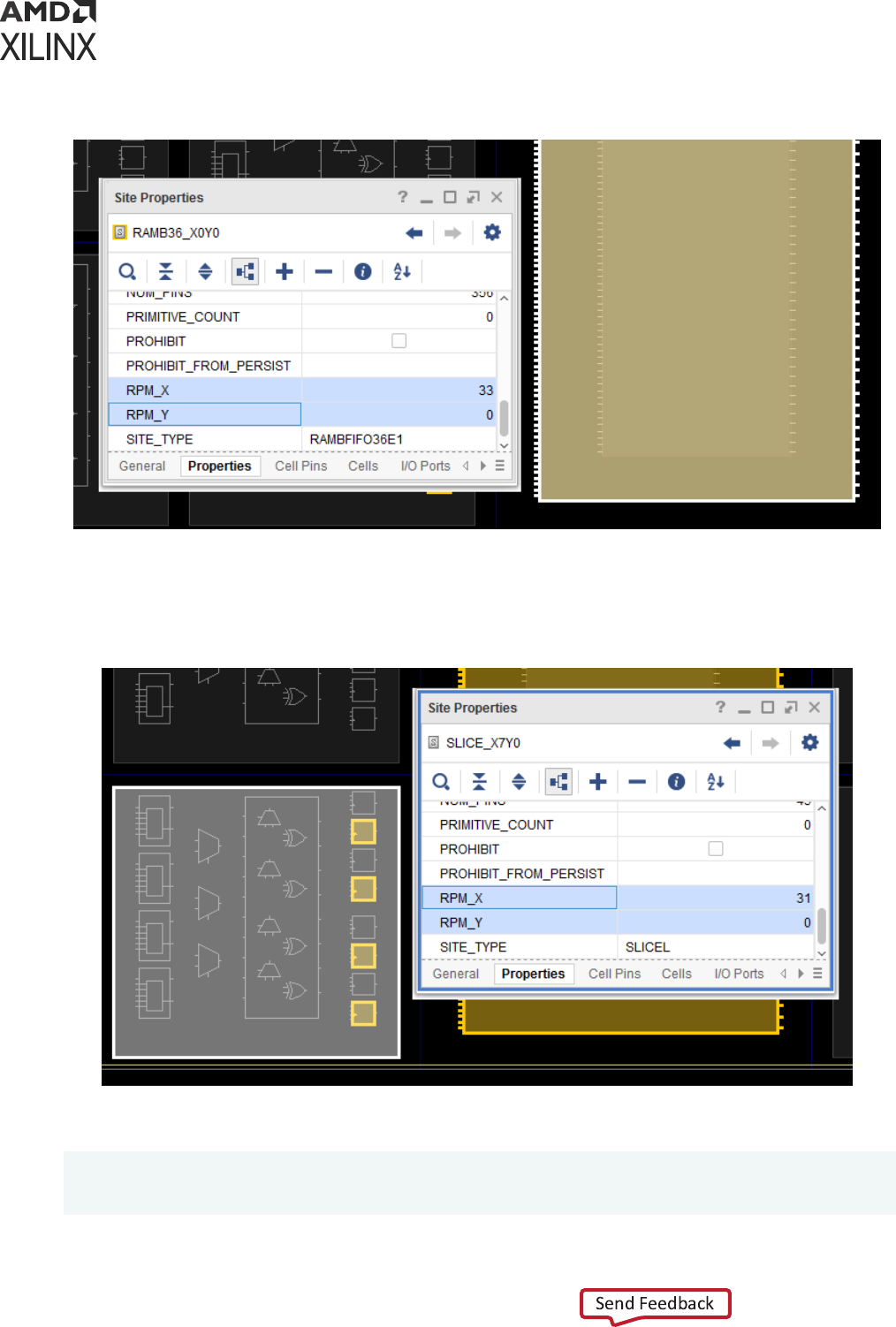

software and IPs. You may still find examples of non-inclusive

language in our older products as we work to make these changes and

align with evolving industry standards. Follow this link for more

information.

Table of Contents

Chapter 1: Introduction.............................................................................................. 5

Migrating From UCF Constraints to XDC Constraints.............................................................5

Navigating Content by Design Process.................................................................................... 5

About XDC Constraints............................................................................................................... 6

Chapter 2: Constraints Methodology.................................................................. 8

About Constraints Methodology............................................................................................... 8

Organizing Your Constraints......................................................................................................8

Ordering Your Constraints....................................................................................................... 12

Entering Constraints................................................................................................................. 18

Creating Synthesis Constraints................................................................................................58

Creating Implementation Constraints....................................................................................64

Constraints Scoping.................................................................................................................. 67

Constraints Efficiency................................................................................................................74

Chapter 3: Defining Clocks...................................................................................... 79

About Clocks.............................................................................................................................. 79

Primary Clocks........................................................................................................................... 81

Virtual Clocks............................................................................................................................. 83

Generated Clocks...................................................................................................................... 84

Clock Groups..............................................................................................................................93

Clock Latency, Jitter, and Uncertainty.....................................................................................96

Chapter 4: Constraining I/O Delay......................................................................99

About Constraining I/O Delay................................................................................................. 99

Input Delay.................................................................................................................................99

Output Delay............................................................................................................................102

Chapter 5: Timing Exceptions.............................................................................. 106

About Timing Exceptions....................................................................................................... 106

Multicycle Paths.......................................................................................................................106

False Paths............................................................................................................................... 122

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 2

Min/Max Delays.......................................................................................................................126

Case Analysis........................................................................................................................... 134

Disabling Timing Arcs............................................................................................................. 136

Chapter 6: CDC Constraints...................................................................................138

About CDC Constraints...........................................................................................................138

Constraining Bus Skew........................................................................................................... 138

Chapter 7: XDC Precedence...................................................................................144

About XDC Precedence...........................................................................................................144

XDC Constraints Order........................................................................................................... 144

Exceptions Priority.................................................................................................................. 144

Chapter 8: Physical Constraints..........................................................................148

About Physical Constraints.................................................................................................... 148

Netlist Constraints...................................................................................................................149

I/O Constraints........................................................................................................................ 151

Placement Constraints........................................................................................................... 152

Routing Constraints................................................................................................................ 154

Configuration Constraints......................................................................................................156

Chapter 9: Defining Relatively Placed Macros........................................... 157

About Relatively Placed Macros.............................................................................................157

Defining Sets of Design Elements.........................................................................................157

Creating an RPM......................................................................................................................158

Assigning Cells to RPM Sets...................................................................................................158

Assigning Relative Locations................................................................................................. 161

Assigning a Fixed Location to an RPM..................................................................................165

XDC Macros..............................................................................................................................166

Converting RPMs to XDC Macros.......................................................................................... 180

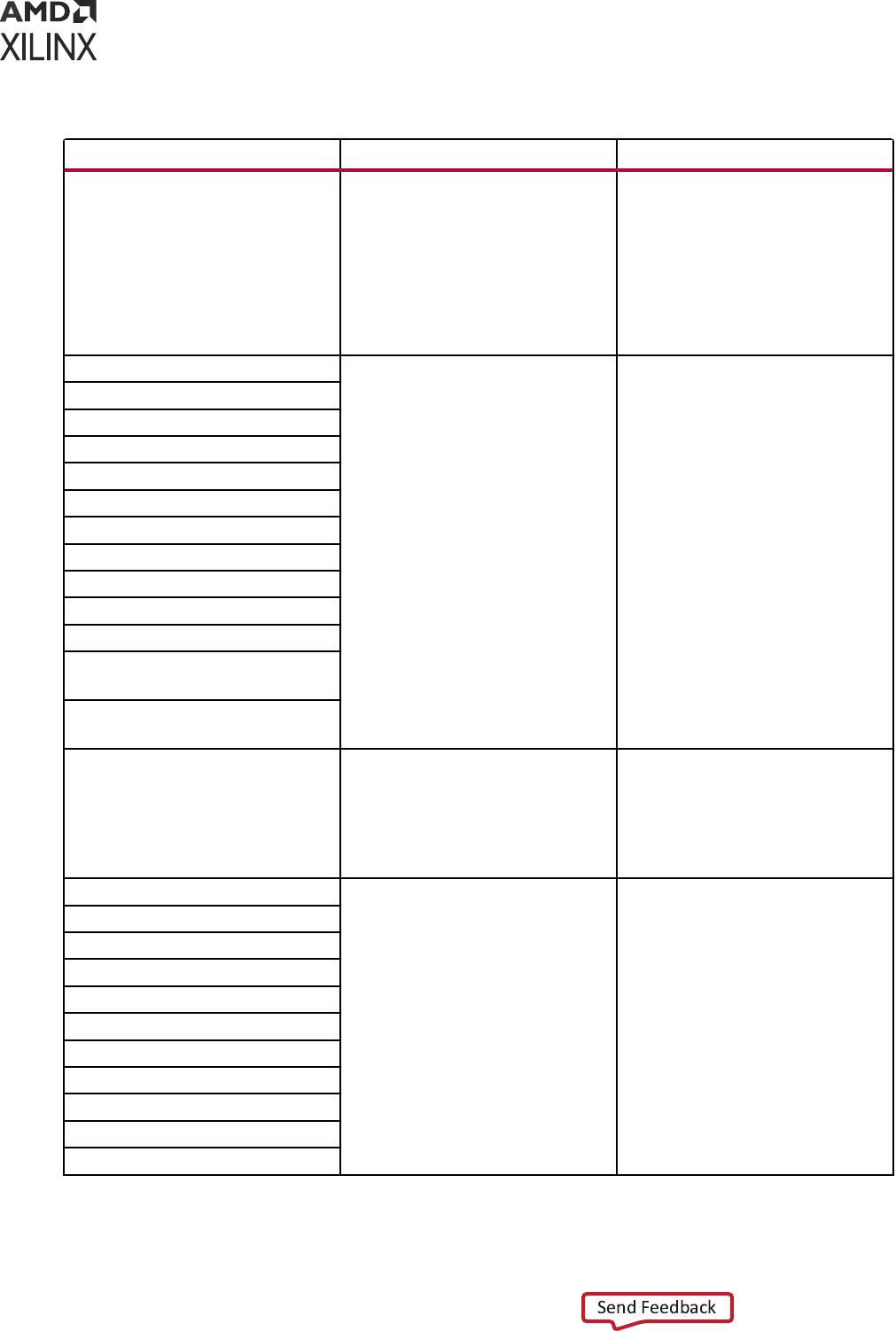

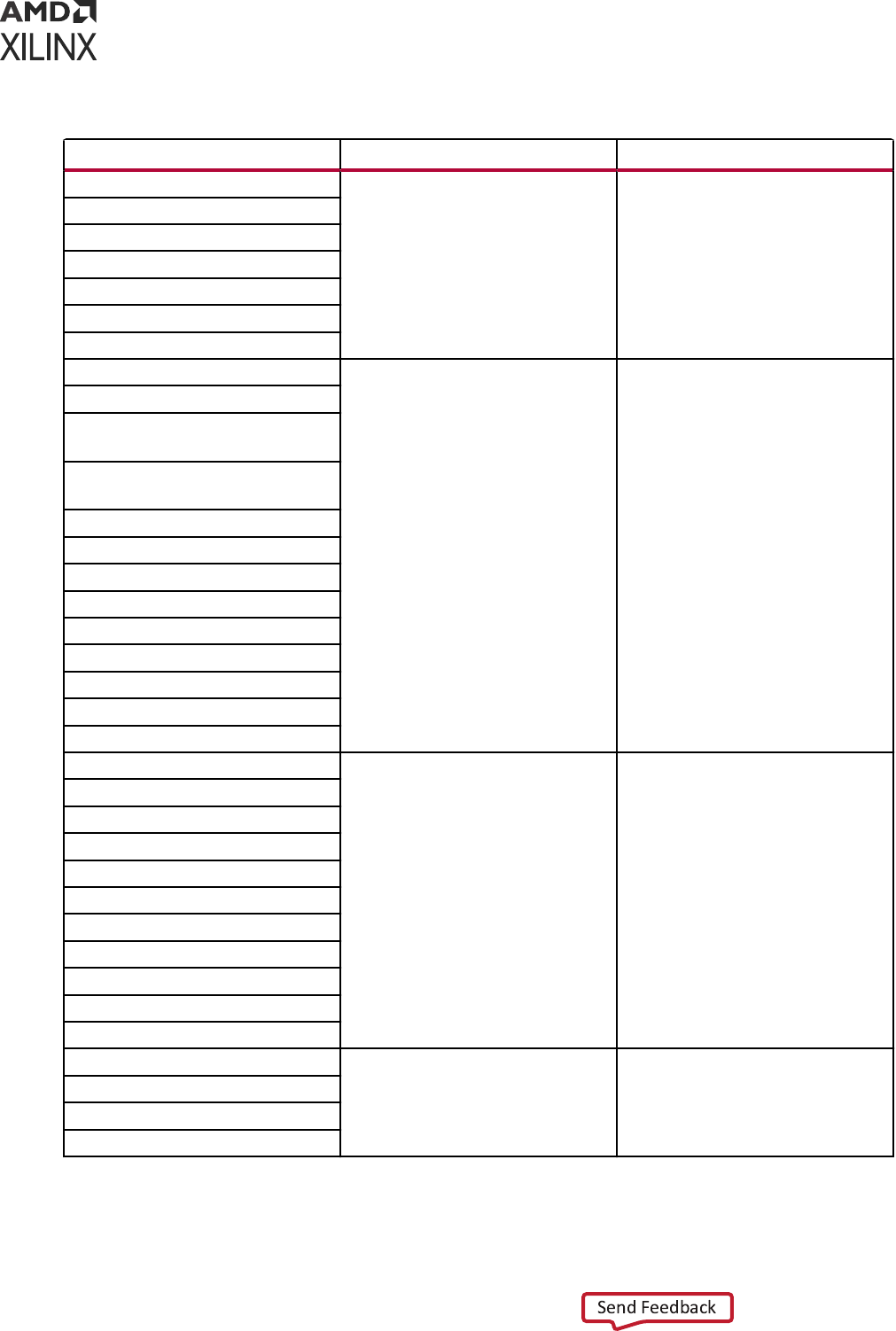

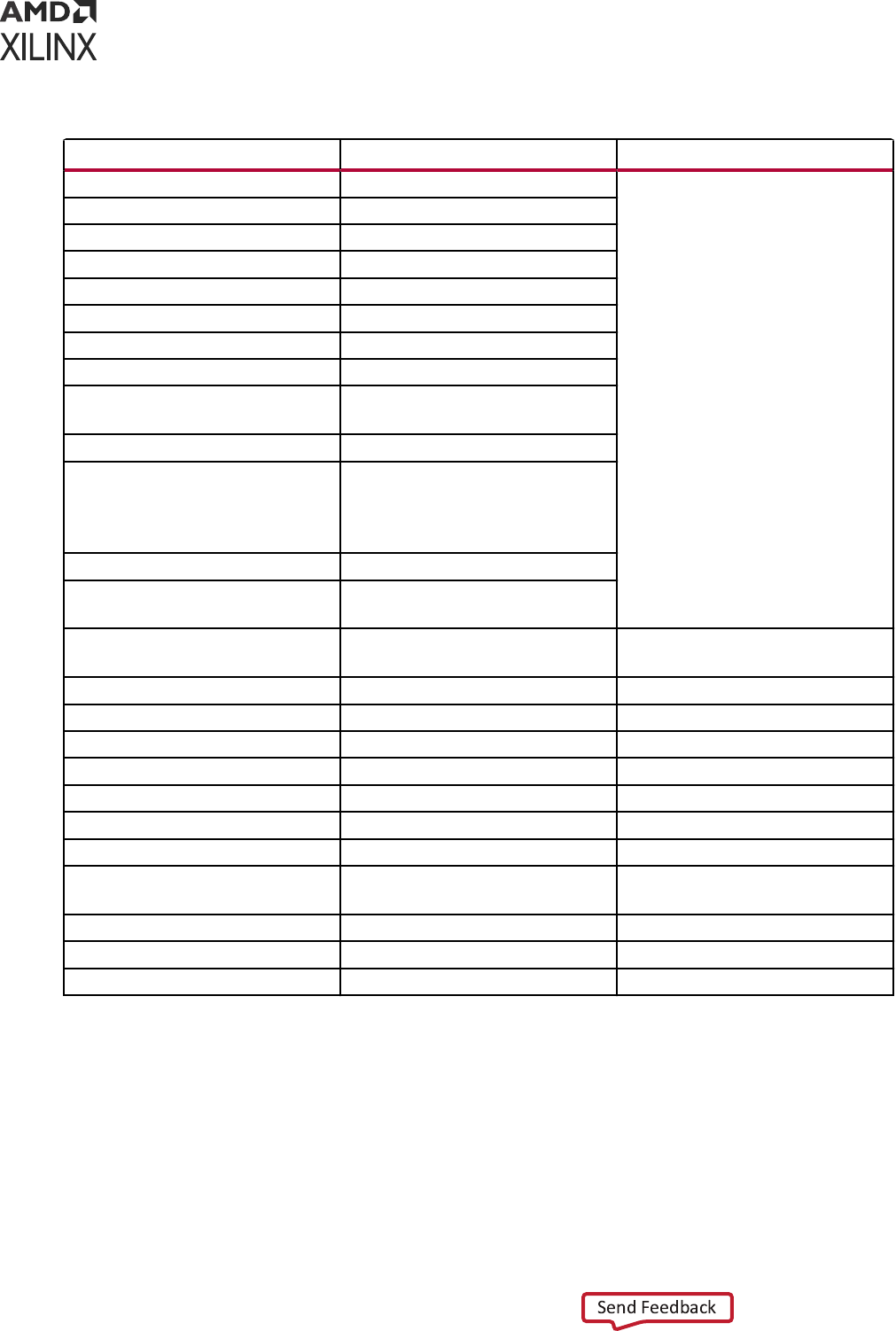

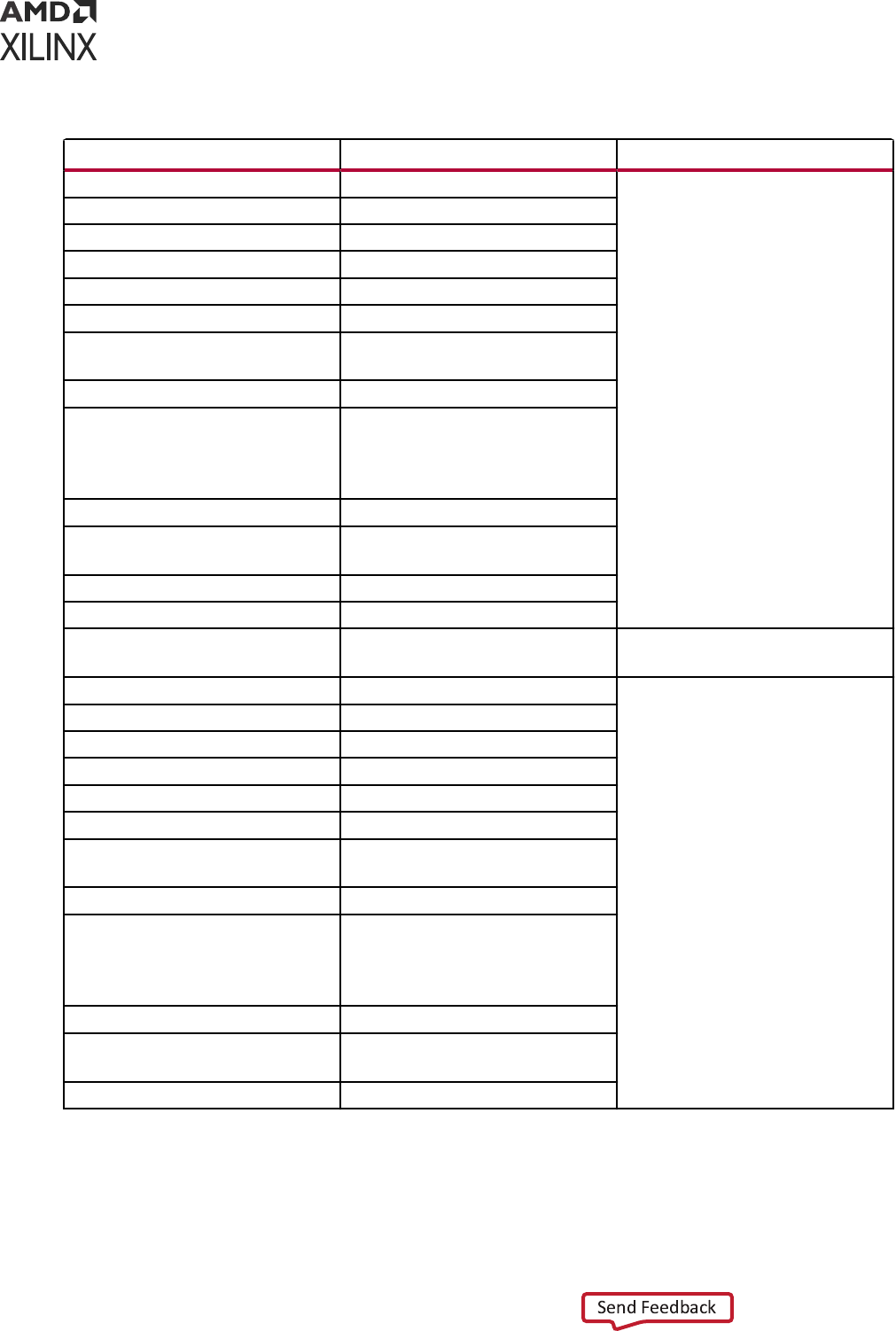

Appendix A: Supported XDC and SDC Commands....................................182

Valid Commands in an XDC File.............................................................................................182

Supported SDC Commands................................................................................................... 183

Unsupported SDC Commands...............................................................................................192

Appendix B: Additional Resources and Legal Notices........................... 194

Xilinx Resources.......................................................................................................................194

Solution Centers...................................................................................................................... 194

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 3

Documentation Navigator and Design Hubs...................................................................... 194

References................................................................................................................................195

Training Resources..................................................................................................................195

Revision History.......................................................................................................................196

Please Read: Important Legal Notices................................................................................. 196

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 4

Chapter 1

Introduction

Migrating From UCF Constraints to XDC

Constraints

The Xilinx

®

Vivado

®

Integrated Design Environment (IDE) uses Xilinx Design Constraints (XDC),

and does not support the legacy User Constraints File (UCF) format.

There are key dierences between Xilinx Design Constraints (XDC) and User Constraints File

(UCF) constraints. XDC constraints are based on the standard Synopsys™ Design Constraints

(SDC) format. SDC has been in use and evolving for more than 20 years, making it the most

popular and proven format for describing design constraints.

VIDEO:

For training on migrang UCF constraints to XDC, see the Vivado Design Suite QuickTake Video:

Migrang UCF Constraints to XDC.

If you are familiar with UCF but new to XDC, see the "Dierences Between XDC and UCF

Constraints" secon in Migrang UCF Constraints to XDC chapter of the ISE to Vivado Design

Suite Migraon Guide (UG911). That chapter also describes how to convert exisng UCF les to

XDC as a starng point for creang XDC constraints.

IMPORTANT!

XDC has fundamental dierences from UCF that must be understood in order to properly

constrain a design. The UCF to XDC conversion ulity is not a replacement for properly understanding and

creang XDC constraints. Each XDC constraint is described in this User Guide.

Navigating Content by Design Process

Xilinx

®

documentaon is organized around a set of standard design processes to help you nd

relevant content for your current development task. All Versal

®

ACAP design process Design

Hubs and the Design Flow Assistant materials can be found on the Xilinx.com website. This

document covers the following design processes:

Chapter 1: Introduction

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 5

• Hardware, IP, and Plaorm Development: Creang the PL IP blocks for the hardware

plaorm, creang PL kernels, funconal simulaon, and evaluang the Vivado

®

ming,

resource use, and power closure. Also involves developing the hardware plaorm for system

integraon. Topics in this document that apply to this design process include:

• Dedicated Hardware Resources

• IP and Sub-Module Constraining with XDC

About XDC Constraints

XDC constraints are a combinaon of industry standard Synopsys Design Constraints (SDC

version 1.9) and Xilinx proprietary physical constraints.

XDC constraints have the following properes:

• They are not simple strings, but are commands that follow the Tcl semanc.

• They can be interpreted like any other Tcl command by the Vivado Tcl interpreter.

• They are read in and parsed sequenally the same as other Tcl commands.

You can enter XDC constraints in several ways, at dierent points in the ow.

• Store the constraints in one or more XDC les.

To load the XDC le in memory, do one of the following:

○ Use the read_xdc command.

○ Add it to one of your project constraints sets. XDC les only accept the set, list, and

expr built-in Tcl commands. See Appendix A: Supported XDC and SDC Commands for a

complete list of supported commands.

• Generate the constraints with an unmanaged Tcl script.

To execute the Tcl script, do one of the following:

○ Run the source command.

○ Use the read_xdc -unmanaged command.

○ Add the Tcl script to one of your project constraints sets.

TIP:

Unlike XDC les, unmanaged Tcl scripts can include any common Tcl command for selecng design

objects and dening design constraints, including condional and looping control structures.

Chapter 1: Introduction

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 6

IMPORTANT! The Vivado Design Suite allows you to mix XDC les and Tcl scripts in the same constraints

set. Modied constraints are saved back to their original locaon only if they originally came from an XDC

le, and not from an unmanaged Tcl script. A constraint generated by a Tcl script is not managed by the

Vivado Design Suite and cannot be interacvely modied. For more informaon, see Chapter 2:

Constraints Methodology.

Note: For XDC constraints, there is a dierence in behavior between the commands source and

read_xdc. The constraints imported with the source command are not saved in the checkpoint in the

same order as they are imported. The constraints imported with read_xdc are saved rst and then those

imported with source. To save all the constraints in the same order as they are applied to the design, use

read_xdc -unmanaged instead of source.

To validate the syntax or impact of a parcular constraint aer loading your design in memory,

use the Tcl Console and the Vivado Design Suite reporng features. This is parcularly powerful

for analyzing and debugging ming constraints and physical constraints.

Chapter 1: Introduction

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 7

Chapter 2

Constraints Methodology

About Constraints Methodology

Design constraints dene the requirements that must be met by the compilaon ow in order for

the design to be funconal on the board. Not all constraints are used by all steps in the

compilaon ow. For example, physical constraints are used only during the implementaon

steps (that is, by the placer and the router).

Because the Xilinx

®

Vivado

®

Integrated Design Environment (IDE) synthesis and implementaon

algorithms are ming-driven, you must create proper ming constraints. Over-constraining or

under-constraining your design makes ming closure dicult. You must use reasonable

constraints that correspond to your applicaon requirements.

Organizing Your Constraints

The Vivado IDE allows you to use one or many constraint les. While using a single constraint le

for the enre compilaon ow might seem more convenient, it can be a challenge to maintain all

the constraints as the design becomes more complex. This is usually the case for designs that use

several IP cores or large blocks developed by dierent teams.

Aer the ming and physical constraints have been imported, independent of the number of

source les or whether the design is in Project or Non-Project mode, all the constraints can be

exported as a single le with the write_xdc command. The constraints are wrien to the

specied output le in the same order that they were read into the project or design. The

command line opon write_xdc -type can be used to select a subset of constraints (ming,

physical, or waiver) to export.

RECOMMENDED:

Xilinx recommends that you separate ming constraints and physical constraints by

saving them into two disnct les. You can also keep the constraints specic to a certain module in a

separate le.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 8

Project Flows

You can add your Xilinx Design Constraints (XDC) les to a constraints set during the creaon of

a new project, or later, from the Vivado IDE menus.

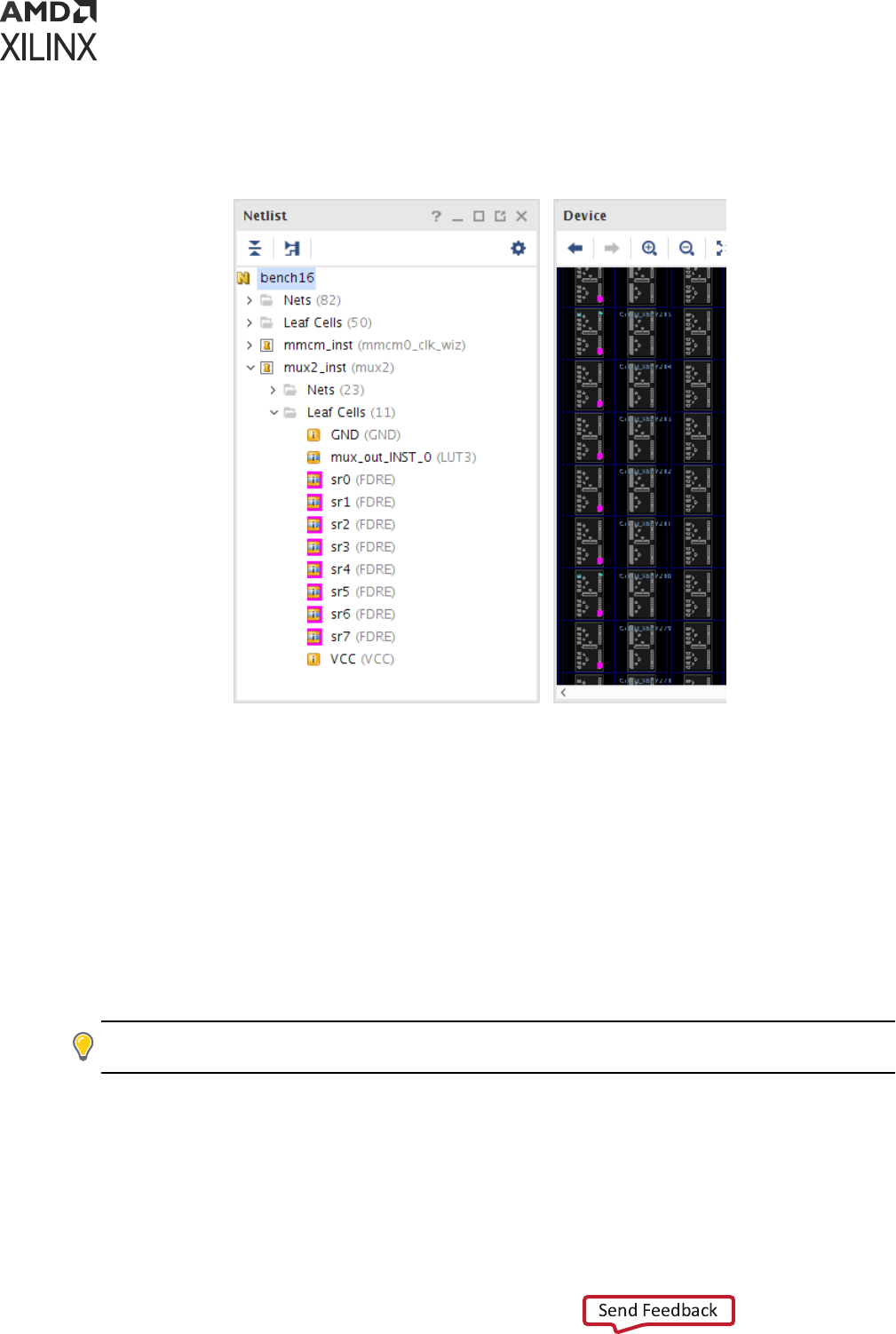

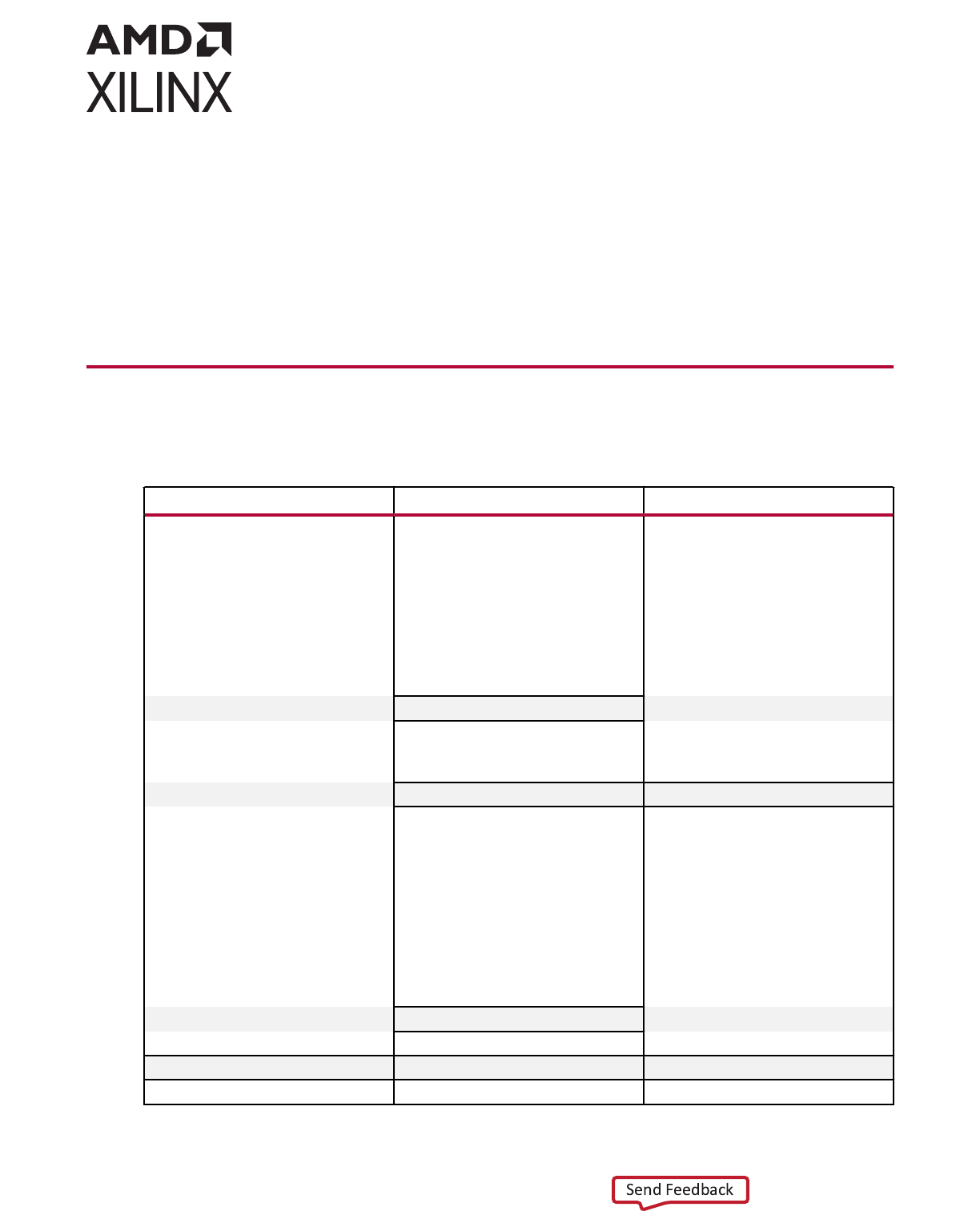

The following gure shows two constraint sets in a project, which are single- or mul-XDC. The

rst constraint set includes two XDC les. The second constraint set uses only one XDC le

containing all the constraints.

Figure 1: Single or Multi XDC

IMPORTANT! If your project contains an IP that uses its own constraints, the corresponding constraint

le does not appear in the constraints set. Instead, it is listed along with the IP source les.

You can also add Tcl scripts to your constraints set as unmanaged constraints or unmanaged Tcl

scripts. The Vivado Design Suite does not write modied constraints back into an unmanaged Tcl

script. Tcl scripts and XDC les are loaded in the same sequence as displayed in the Vivado IDE

(if they belong to the same PROCESSING_ORDER group) or as reported by the command

report_compile_order -constraints.

An XDC le or a Tcl script can be used in several constraints sets if needed. For more informaon

on how to create and add constraint les and constraints sets to your project, see Working with

Constraints in the Vivado Design Suite User Guide: System-Level Design Entry (UG895).

Non-Project Flows

In Non-Project Mode, you must read each le individually before execung the compilaon

commands.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 9

The example script below shows how to use one or more XDC les for synthesis and

implementaon.

Example Script:

read_verilog [glob src/*.v] read_xdc wave_gen_timing.xdc read_xdc

wave_gen_pins.xdc

synth_design -top wave_gen -part xc7k325tffg900-2 opt_design

place_design route_design

Out-of-Context Constraints

In designs using Dynamic Funcon eXchange (DFX), it is common to synthesize parts of the

design in an Out-of-Context (OOC) approach. When such a ow is used, some constraints can be

specied for the OOC synthesis only. For example, clocks that propagate at the input boundary

of the blocks must be dened when the blocks are synthesized OOC. These clocks are dened

inside an OOC XDC le.

In Project Mode:

add_file constraints_ooc.xdc

set_property USED_IN {synthesis out_of_context} [get_files

constraints_ooc.xdc]

The Out-of-Context can also be set on the XDC le through the GUI (property on le

constraints_ooc.xdc).

In Non-Project Mode:

read_xdc -mode out_of_context constraints_ooc.xdc

Synthesis and Implementation Constraint Files

By default, all XDC les and Tcl scripts added to a constraint set are used for both synthesis and

implementaon. Set the USED_IN_SYNTHESIS and USED_IN_IMPLEMENTATION properes on

the XDC le or the Tcl script to change this behavior. This property can take the value of either

TRUE or FALSE.

IMPORTANT!

The DONT_TOUCH aribute does not obey the properes of USED_IN_SYNTHESIS and

USED_IN_IMPLEMENTATION. If you use DONT_TOUCH properes in the synthesis XDC, it is propagated

to implementaon regardless of the value of USED_IN_IMPLEMENTATION. For more informaon about

the DONT_TOUCH aribute, refer to RTL Aributes.

IMPORTANT! If any module (IP/BD/...) is synthesized in Out-Of-Context (OOC) mode, the top-level

synthesis run infers a black box for these modules. Hence, the top-level synthesis constraints will not be

able to reference objects such as pins, nets, cells, etc., that are internal to the OOC module. If some top-

level constraints refer to objects inside any OOC module, you may need to split the constraints into two

les: one XDC le for Synthesis (USED_IN_SYNTHESIS=TRUE / USED_IN_IMPLEMENTATION=FALSE) and

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 10

one XDC le for implementaon (USED_IN_SYNTHESIS=FALSE / USED_IN_IMPLEMENTATION=TRUE).

There is no such limitaon during implementaon since the netlists from the OOC module DCPs are linked

with the netlist produced when synthesizing the top-level design les, and the Vivado Design Suite resolves

the black boxes. The XDC output products that were generated for use during implementaon are applied

along with any user constraints.

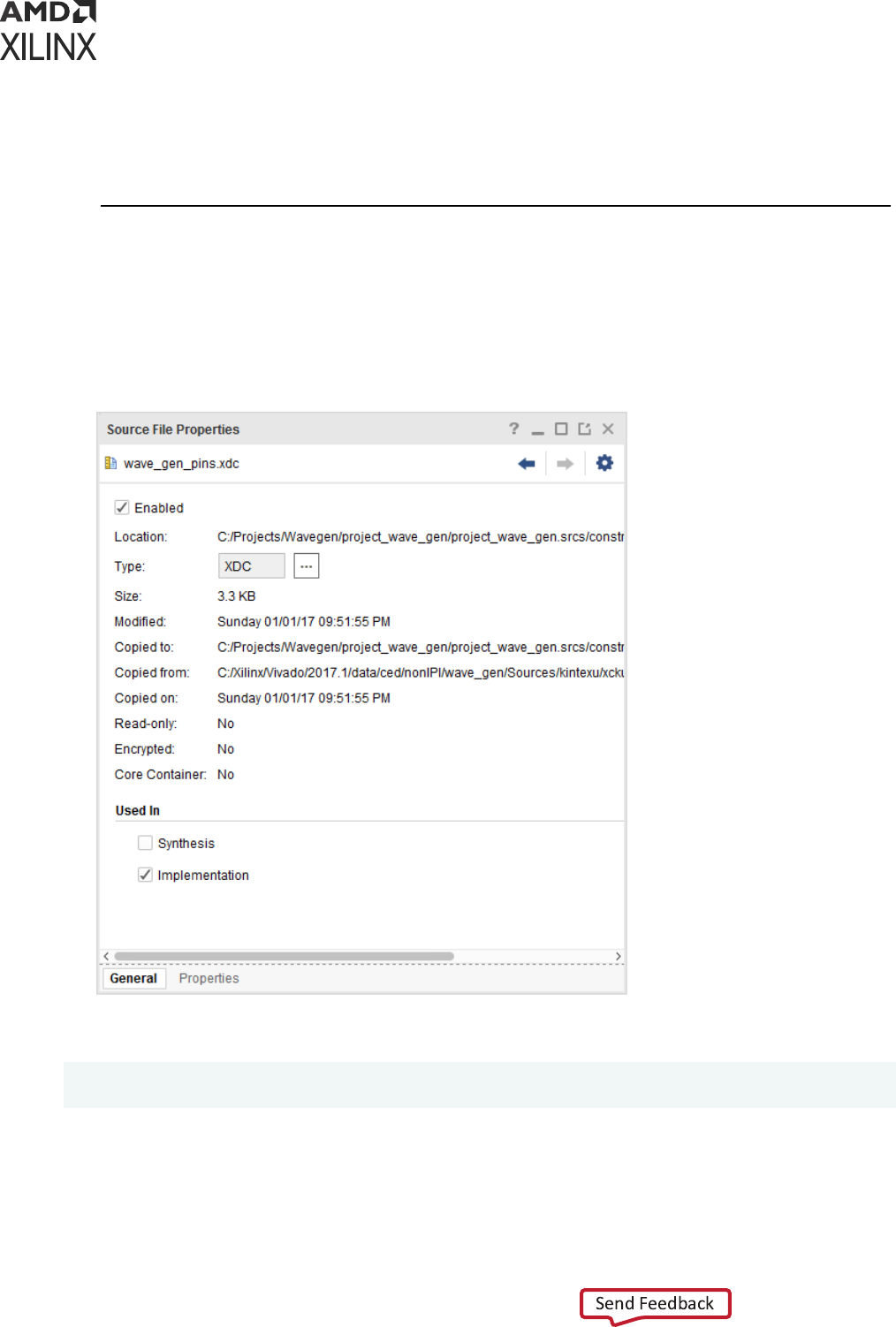

For example, to use a constraint le for implementaon only:

1. Select the constraint le in the Sources window.

2. In the Source File Properes window:

a. Uncheck Synthesis.

b. Check Implementaon.

The equivalent Tcl commands are:

set_property USED_IN_SYNTHESIS false [get_files wave_gen_pins.xdc]

set_property USED_IN_IMPLEMENTATION true [get_files wave_gen_pins.xdc]

When running Vivado in Non-Project Mode, you can read in the constraints directly between any

steps of the ow. The properes USED_IN_SYNTHESIS and USED_IN_IMPLEMENTATION do

not maer in this mode.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 11

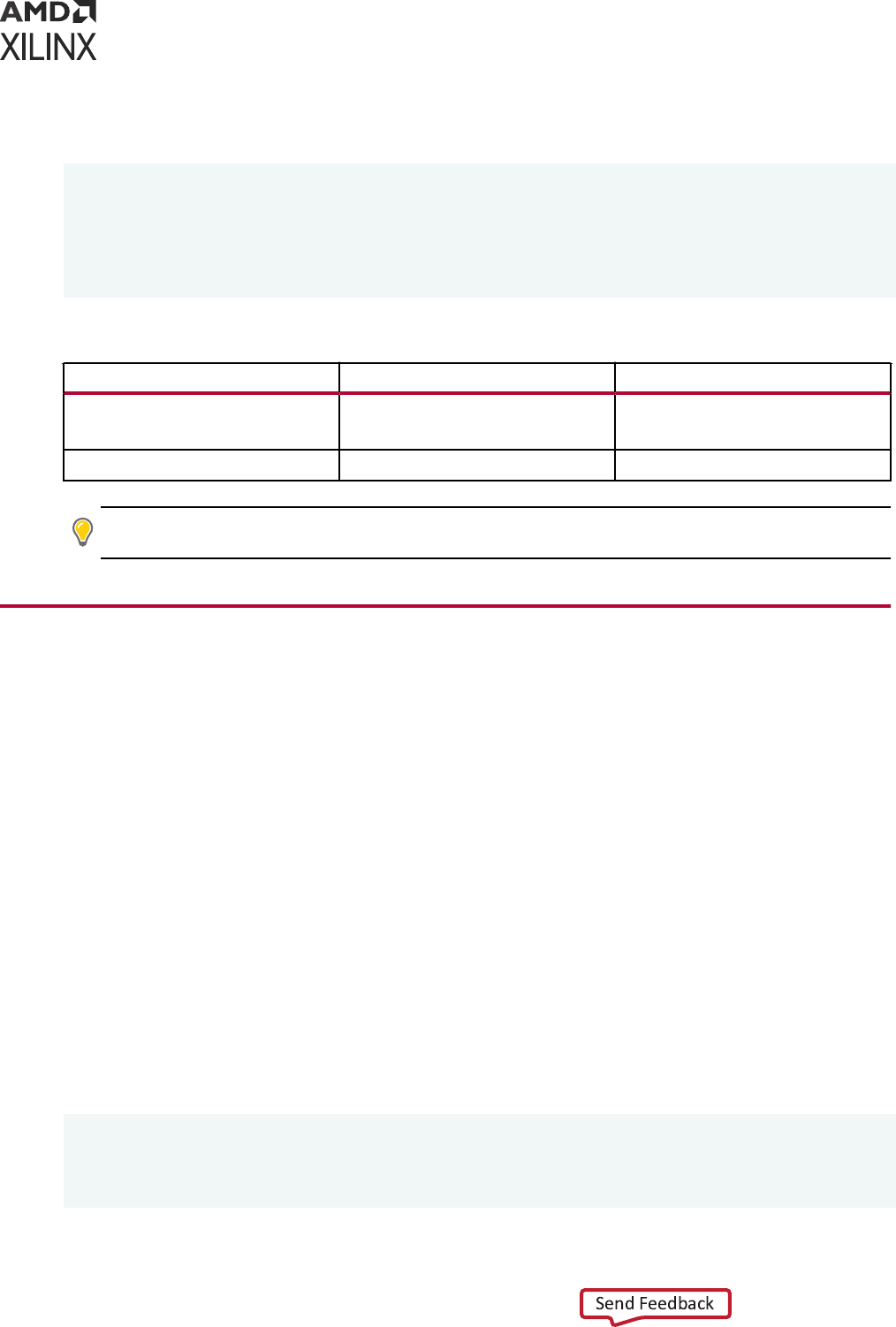

The following compilaon Tcl script shows how to read two XDC les for dierent steps of the

ow:

read_verilog [glob src/*.v]

read_xdc wave_gen_timing.xdc

synth_design -top wave_gen -part xc7k325tffg900-2

read_xdc wave_gen_pins.xdc

opt_design

place_design

route_design

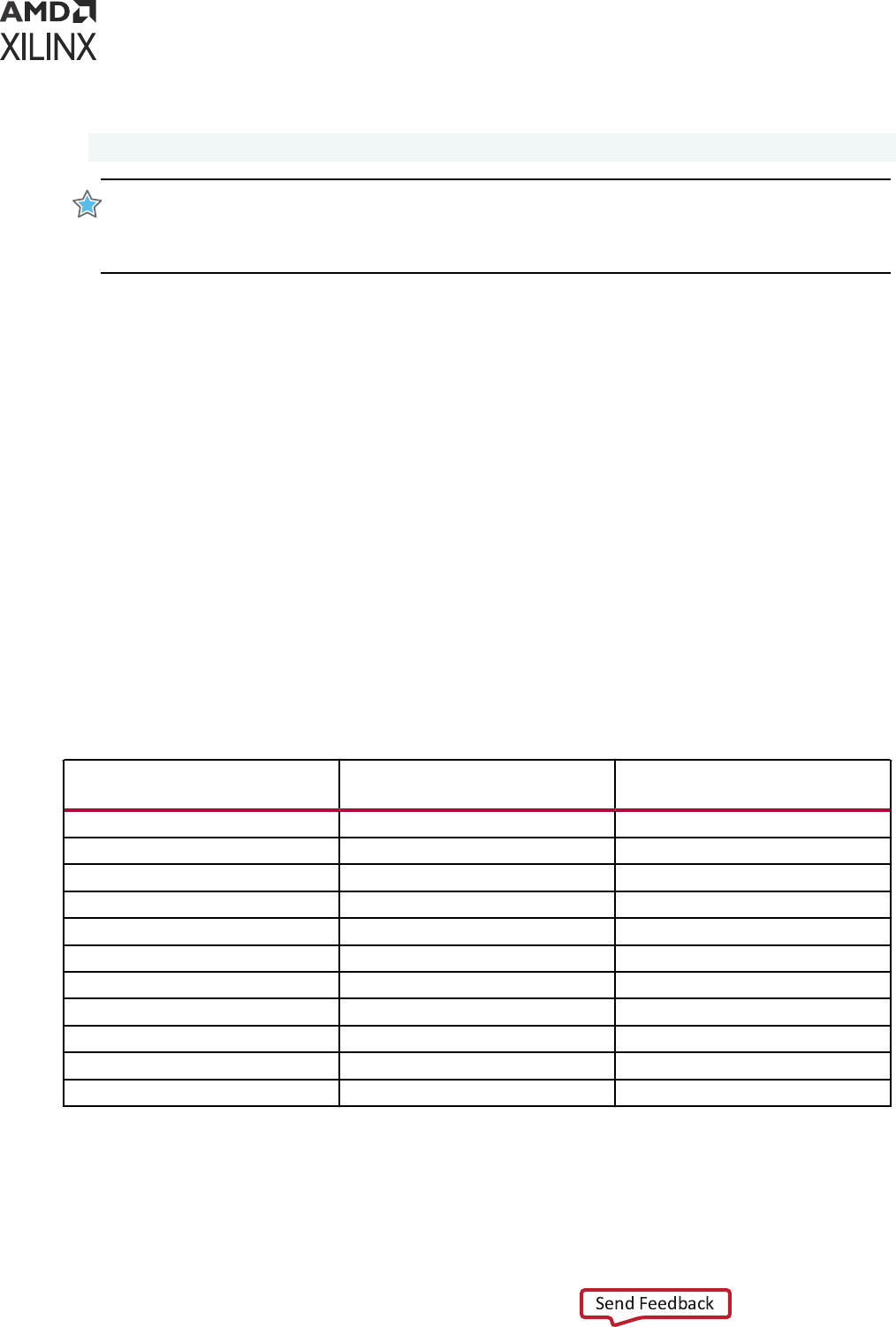

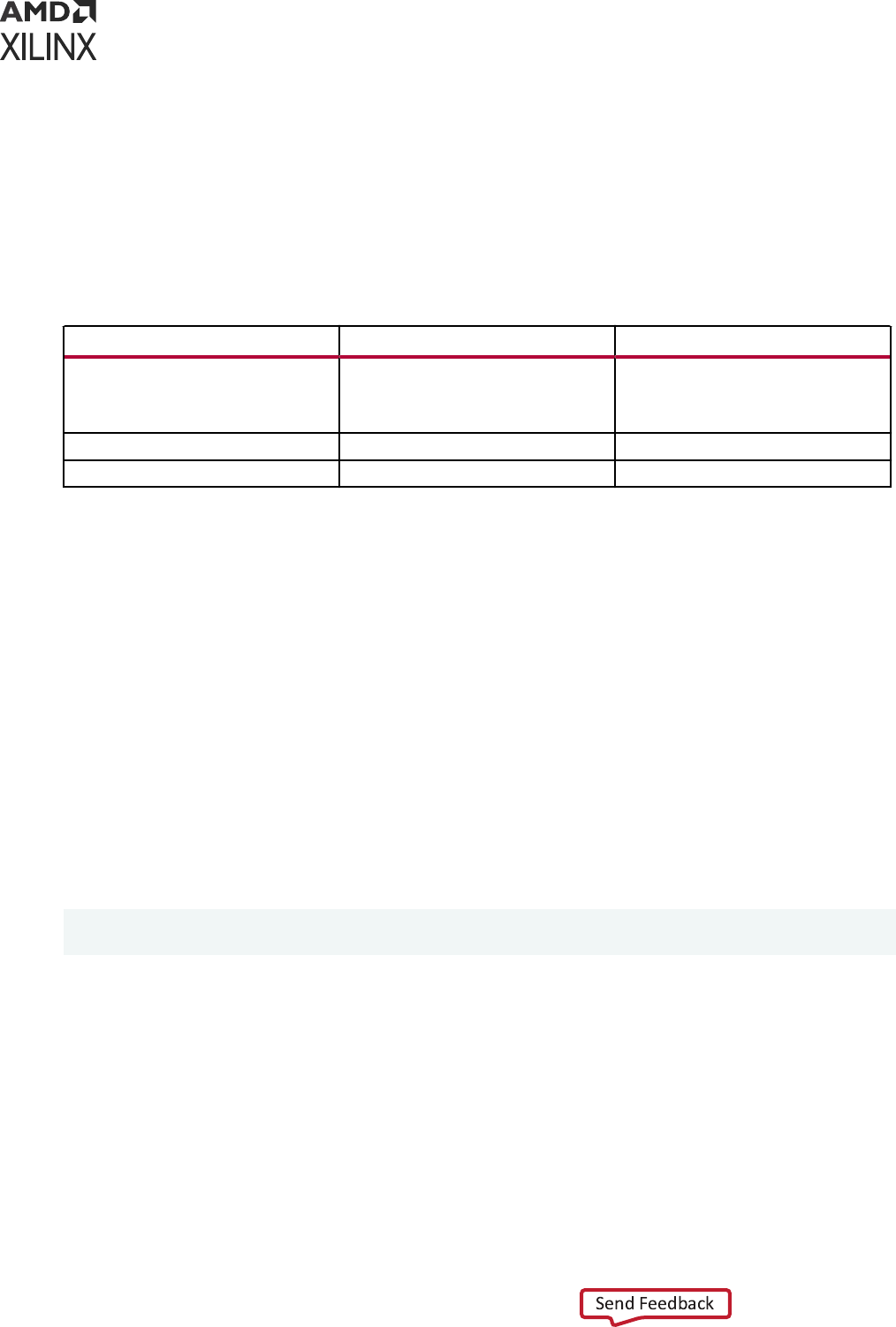

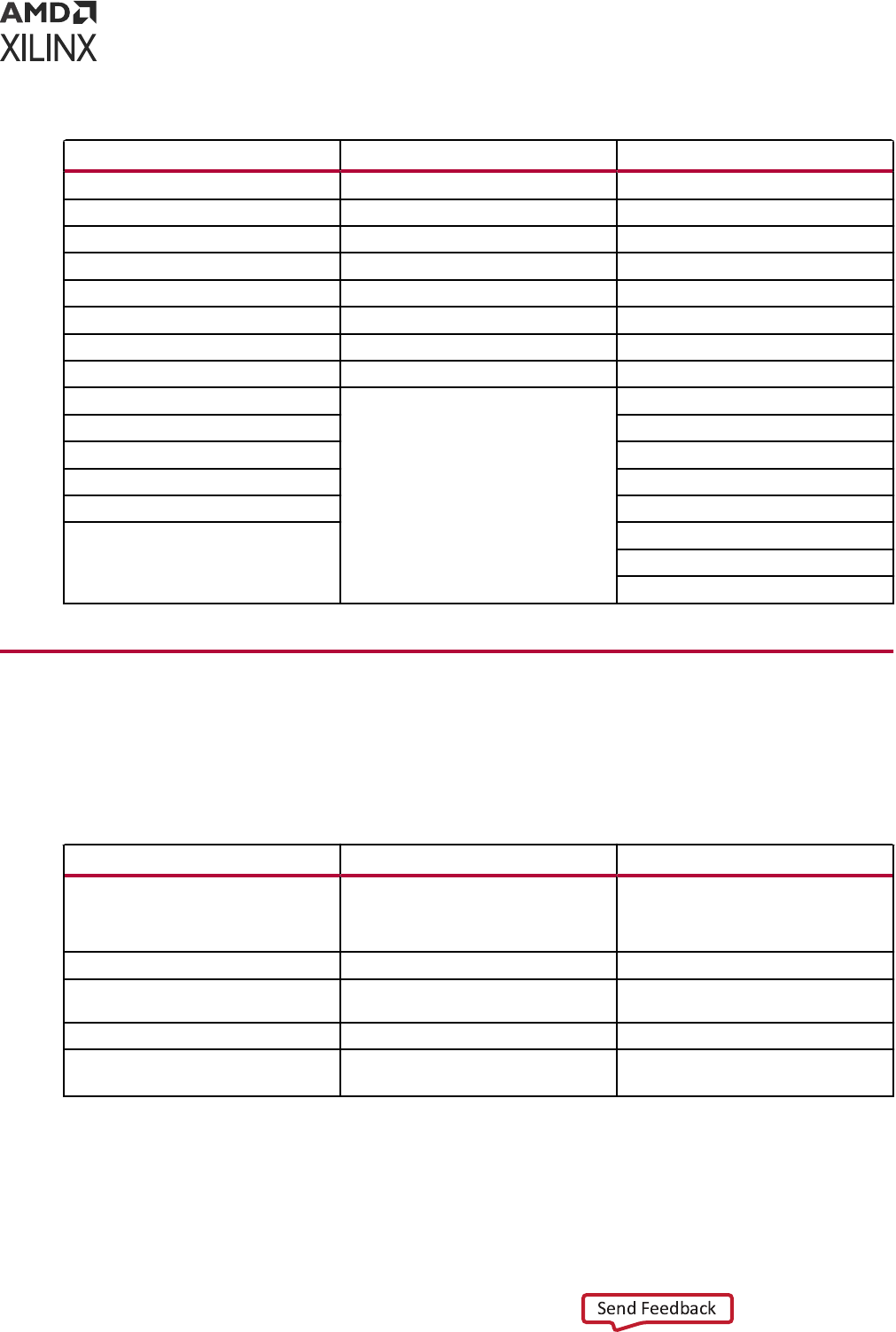

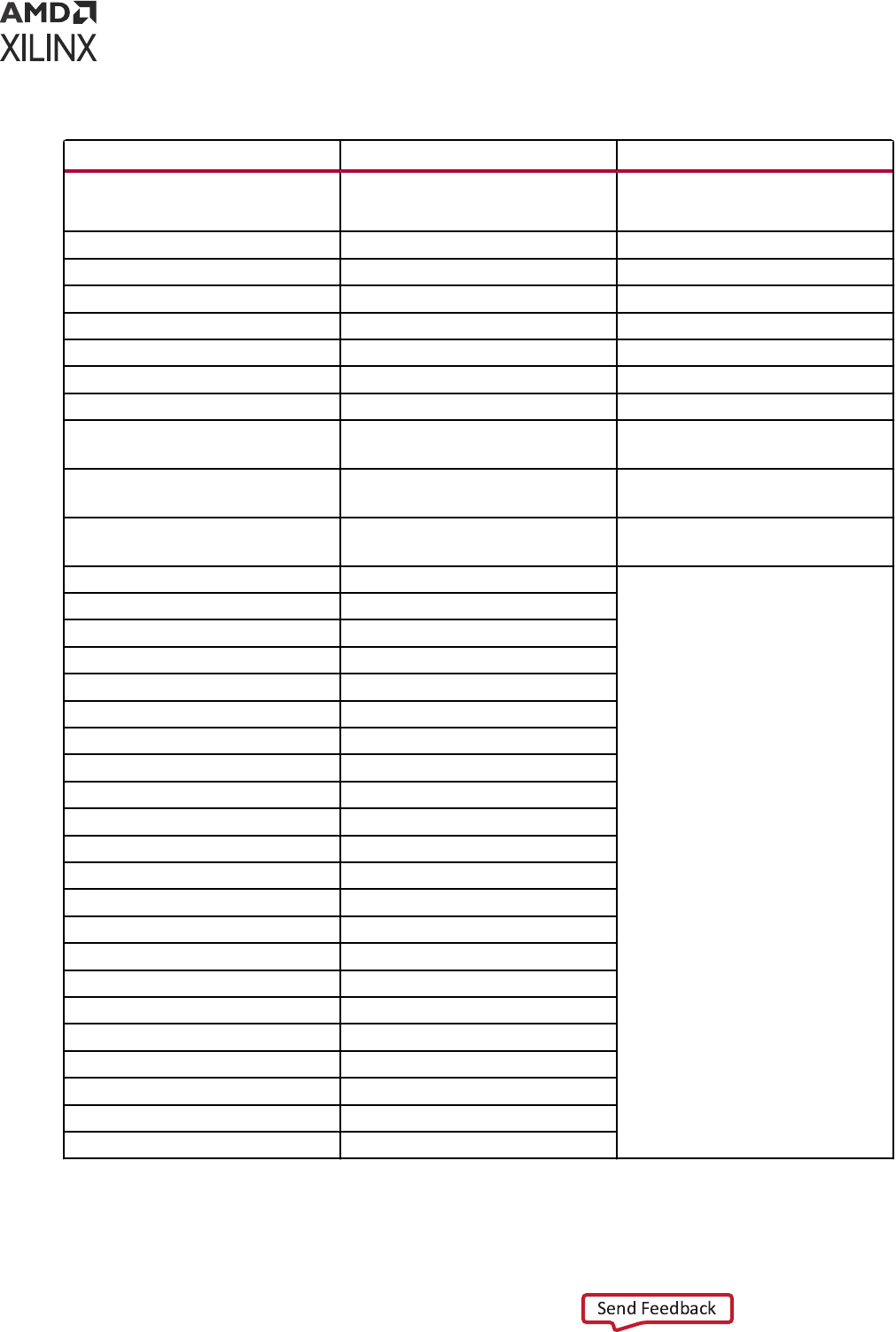

Table 1: Reading XDC Files Before and After Synthesis

File Name File Placement Used For

wave_gen_timing.xdc Before synthesis

• Synthesis

• Implementation

wave_gen_pins.xdc After synthesis

• Implementation

TIP: The constraints read in aer synthesis are applied in addion to the constraints read in before

synthesis.

Ordering Your Constraints

Because XDC constraints are applied sequenally, and are priorized based on clear precedence

rules, you must review the order of your constraints carefully. For more informaon, see Chapter

7: XDC Precedence.

Note: If mulple physical constraints are conicng, the latest constraint wins. For example, if an I/O port

gets assigned a dierent locaon (LOC) through mulple XDC les, the latest locaon assigned to the port

takes precedence.

The Vivado IDE provides full visibility into your design. To validate your constraints step by step:

1. Run the appropriate report commands.

2. Review the messages in the Tcl Console or the Messages window.

Recommended Constraints Sequence

Whether you use one or several XDC les for your design, organize your constraints in the

following sequence.

## Timing Assertions Section # Primary clocks

# Virtual clocks

# Generated clocks # Clock Groups

# Bus Skew constraints

# Input and output delay constraints

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 12

## Timing Exceptions Section # False Paths

# Max Delay / Min Delay # Multicycle Paths

# Case Analysis # Disable Timing

## Physical Constraints Section

# located anywhere in the file, preferably before or after the timing

constraints # or stored in a separate constraint file

Note: The case analysis constraints that change the clock relaonships or clock propagaon should be

dened prior to dening the generated clocks. This includes the case analysis dened on clock buers that

result in the output clock of the buer to be impacted by the case analysis.

Start with the clock denions. The clocks must be created before they can be used by any

subsequent constraints. Any reference to a clock before it has been declared results in an error

and the corresponding constraint is ignored. This is true within an individual constraint le, as

well as across all the XDC les (or Tcl scripts) in your design.

The order of the constraint les maers. You must be sure that the constraints in each le do not

rely on the constraints of another le. If this is the case, you must read the le that contains the

constraint dependencies last. If two constraint les have interdependencies, you must either

merge them manually into one le that contains the proper sequence, or divide the les into

several separate les and order them correctly.

Constraints Sequence Editing

The Vivado IDE constraints manager saves any edited constraint back to its original locaon in

the XDC les, but not in Tcl scripts. Any new constraint is saved at the end of the XDC le

marked as target. In many cases, when your constraints set contains several XDC les, the target

constraint le is not the last le in the list, and will not be loaded last when opening or reloading

your design. As a consequence, the constraints sequence saved to constraint source les can be

dierent from the one you had previously in memory.

IMPORTANT!

You must verify that the nal sequence stored in the constraint les sll works as expected.

If you must modify the sequence, you must modify it by directly eding the constraint les. This is

especially important for ming constraints.

Constraint Files Order

In a project ow without any IP, all the constraints are located in a constraints set. By default, the

order of the XDC les (or Tcl scripts) displayed in the Vivado IDE denes the read sequence used

by the tool when loading an elaborated or synthesized design into memory. The le at the top of

the list is read in rst, and the boom one is read in last. You can change the order by simply

selecng the le in the IDE, and moving it to the desired place in the list.

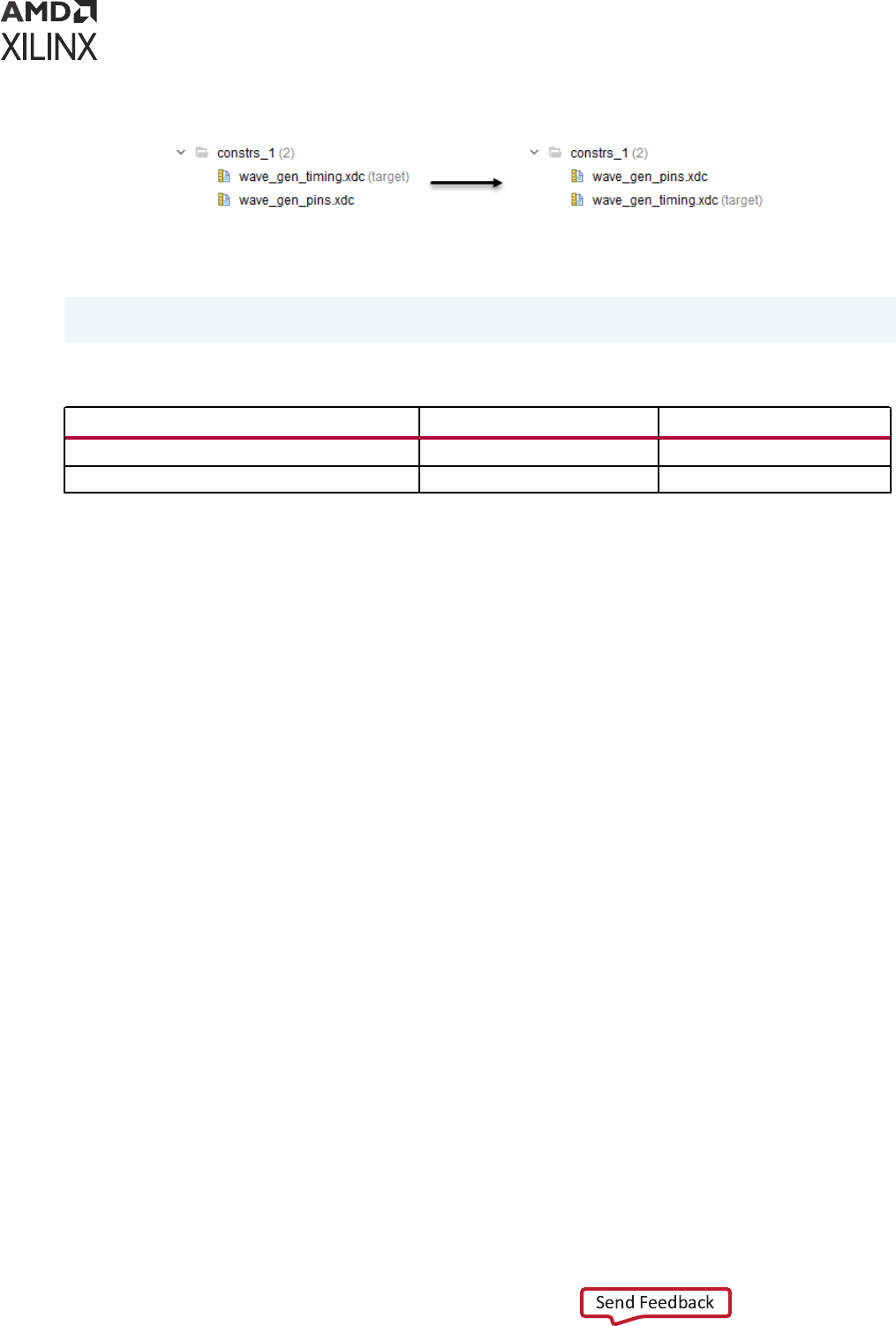

For example, in the following gure, the le wave_gen_pin.xdc was moved to before the le

wave_gen_timing.xdc by using drag and drop.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 13

Figure 2: Changing XDC File Order in the Vivado IDE Example

The equivalent Tcl command is:

reorder_files -fileset constrs_1 -before [get_files wave_gen_timing.xdc] \

[get_files wave_gen_pins.xdc]

Table 2: File Order Before and After

File Order (Before) Order (After)

wave_gen_timing.xdc 1 2

wave_gen_pins.xdc 2 1

In Non-Project Mode, the sequence of the read_xdc calls determine the order in which the

constraint les are evaluated.

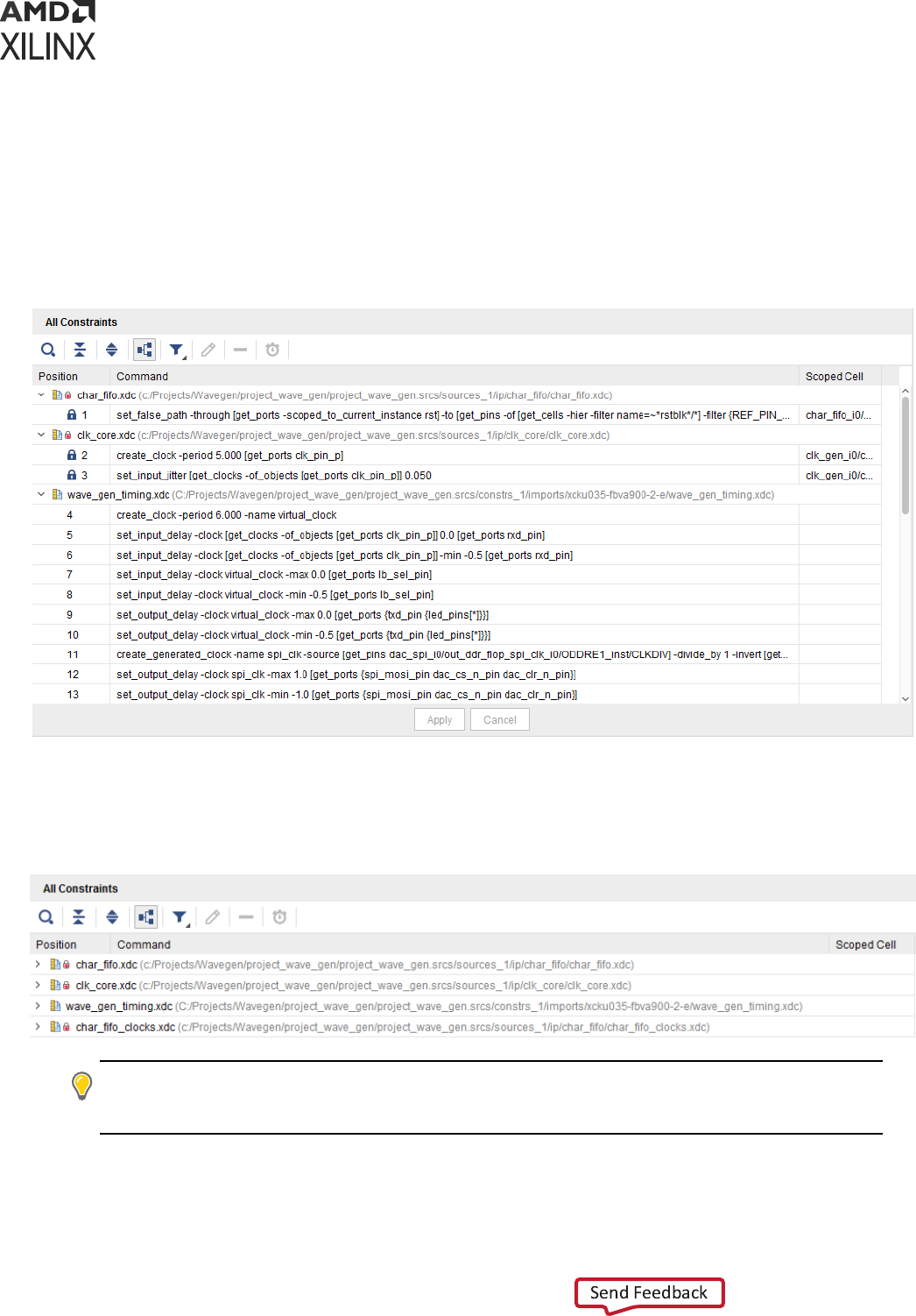

Constraint Files Order with IP Cores

Many IP cores are delivered with one or more XDC les. When such IP cores are generated

within your RTL project, their XDC les are also used during the various design compilaon

steps.

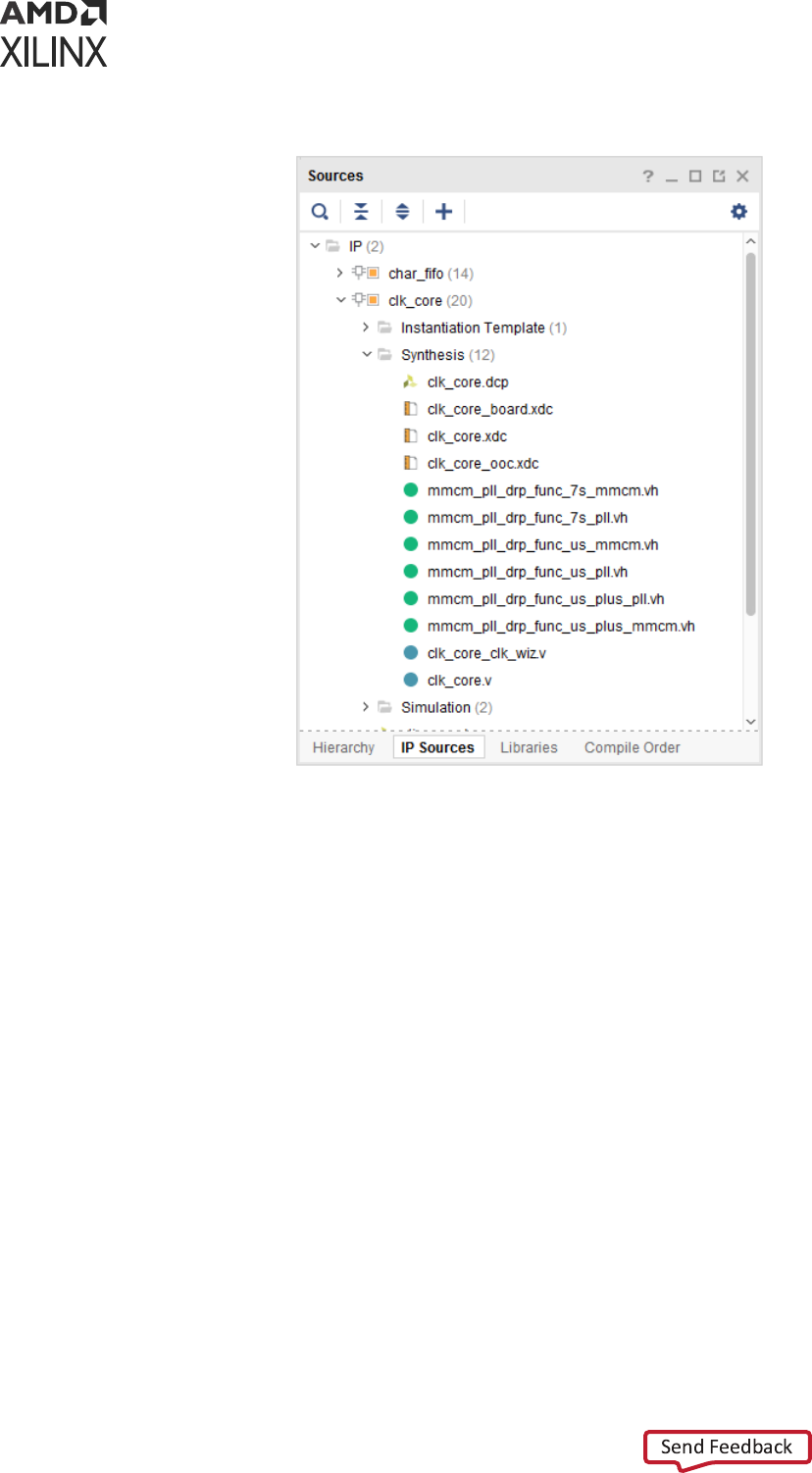

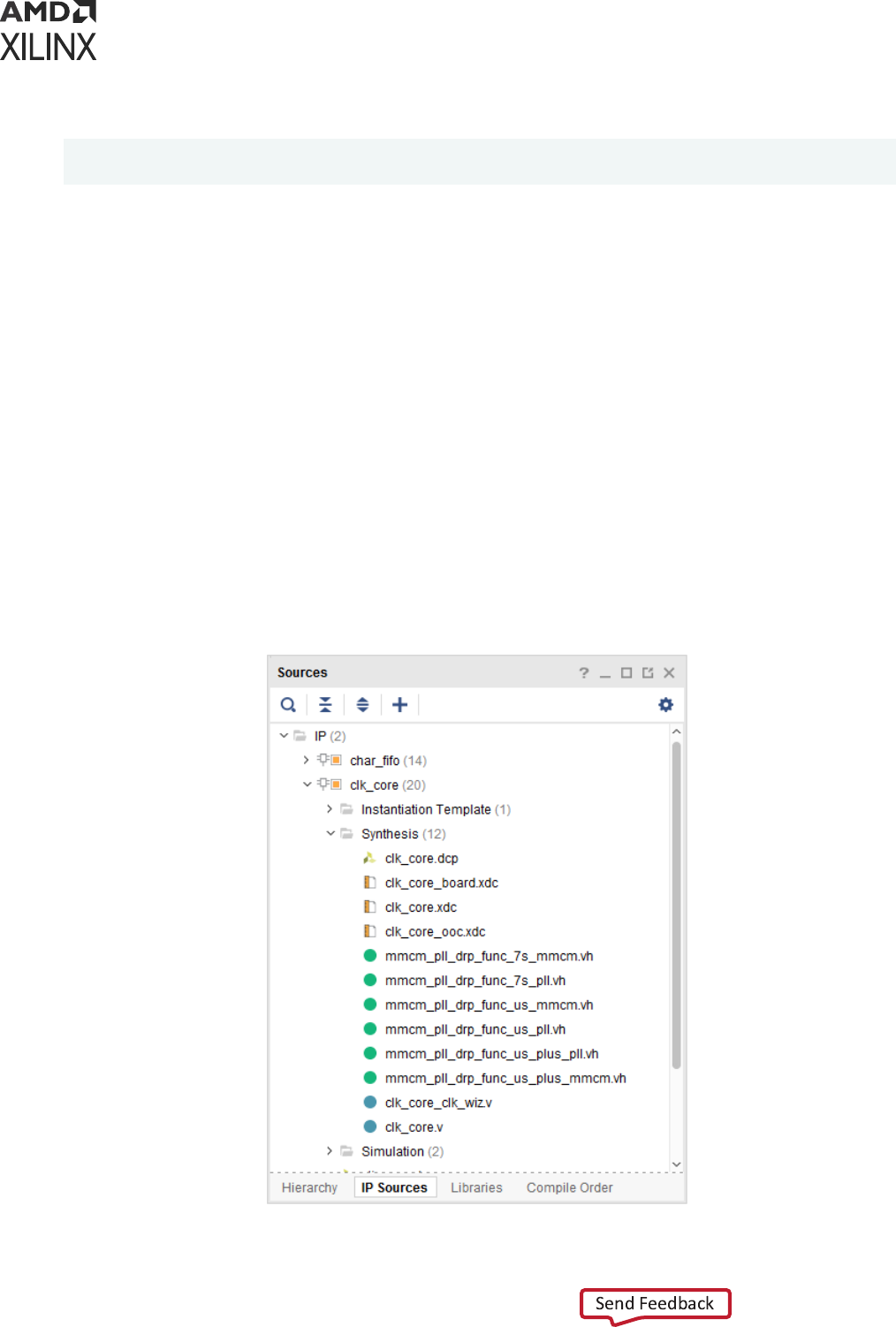

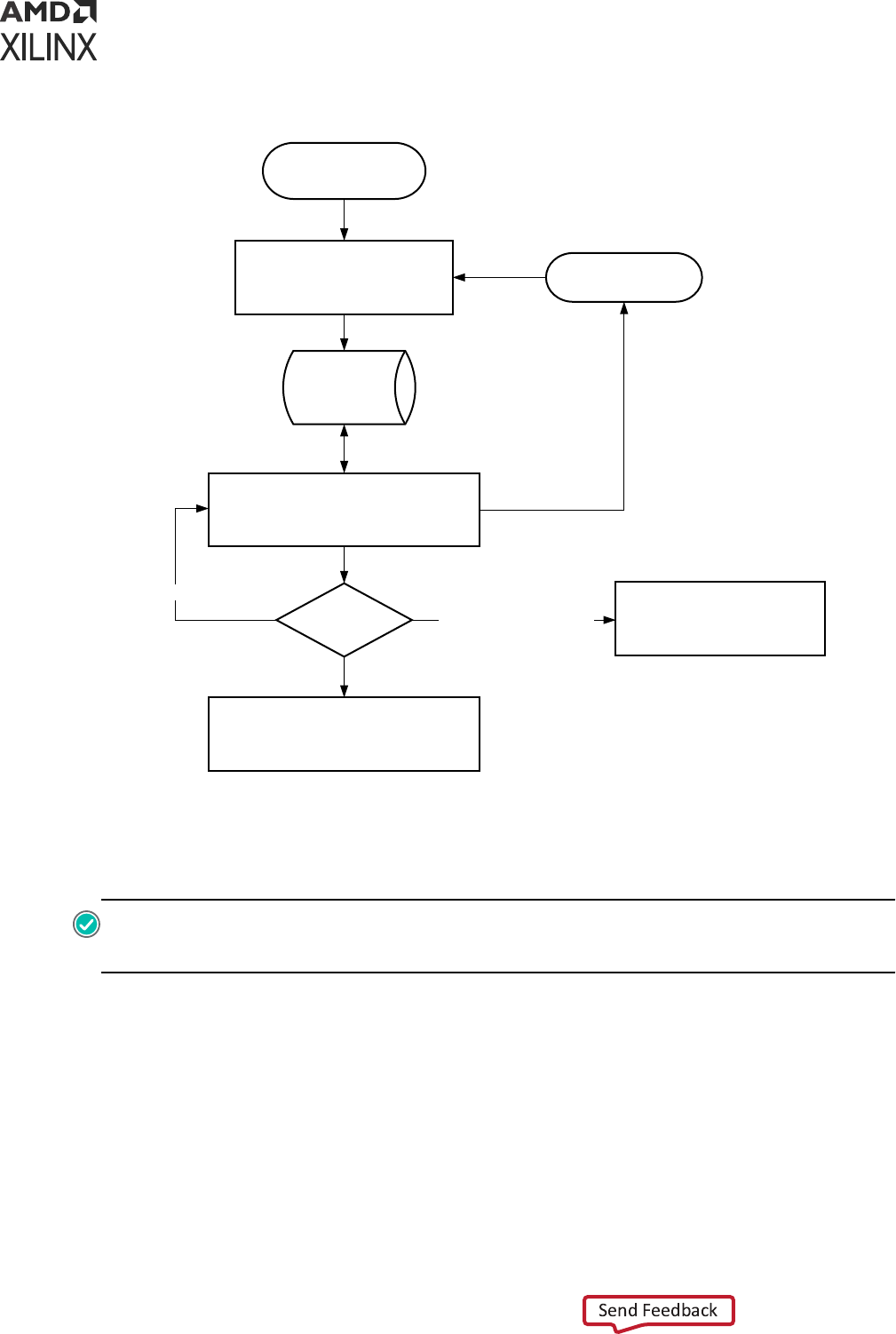

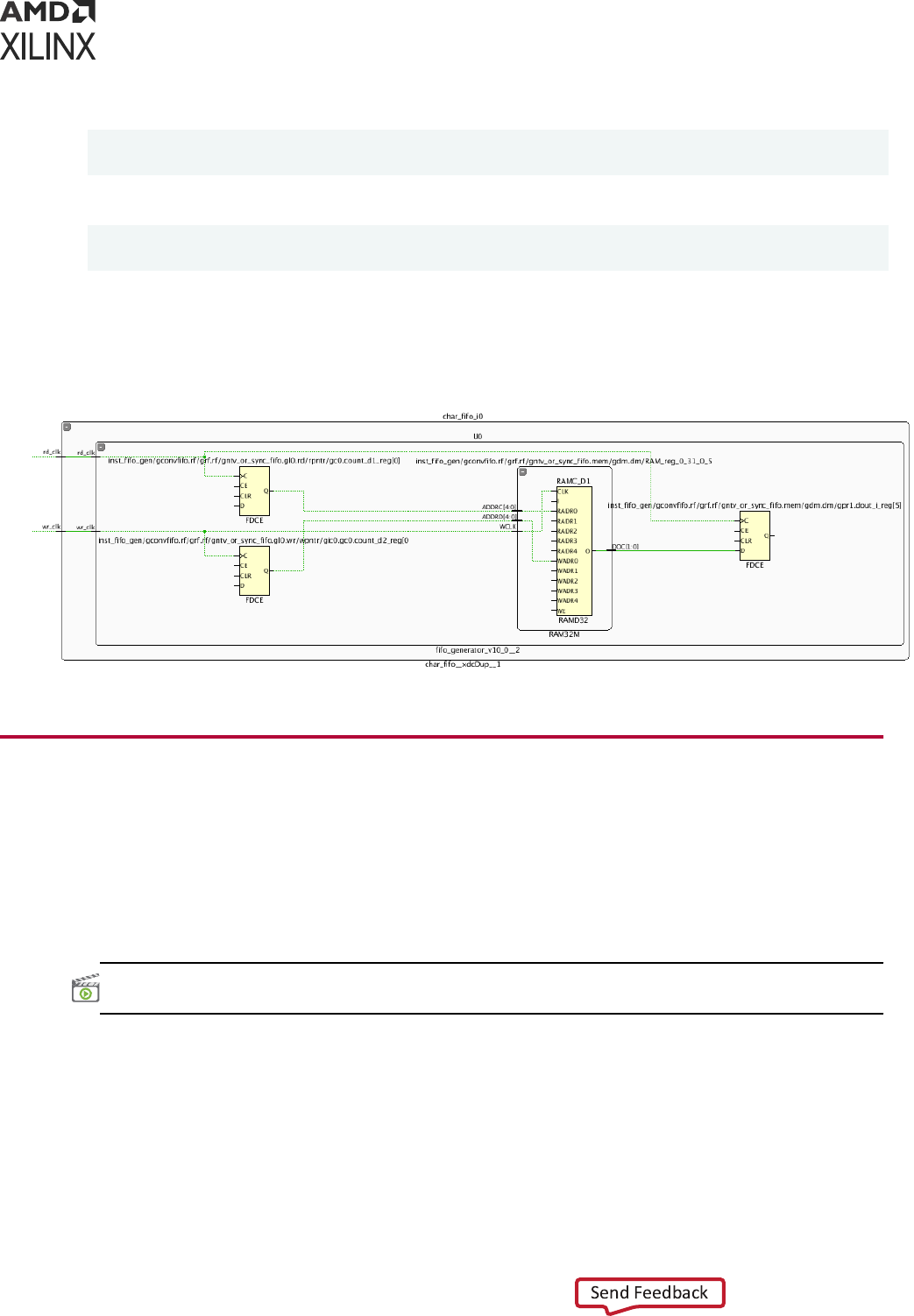

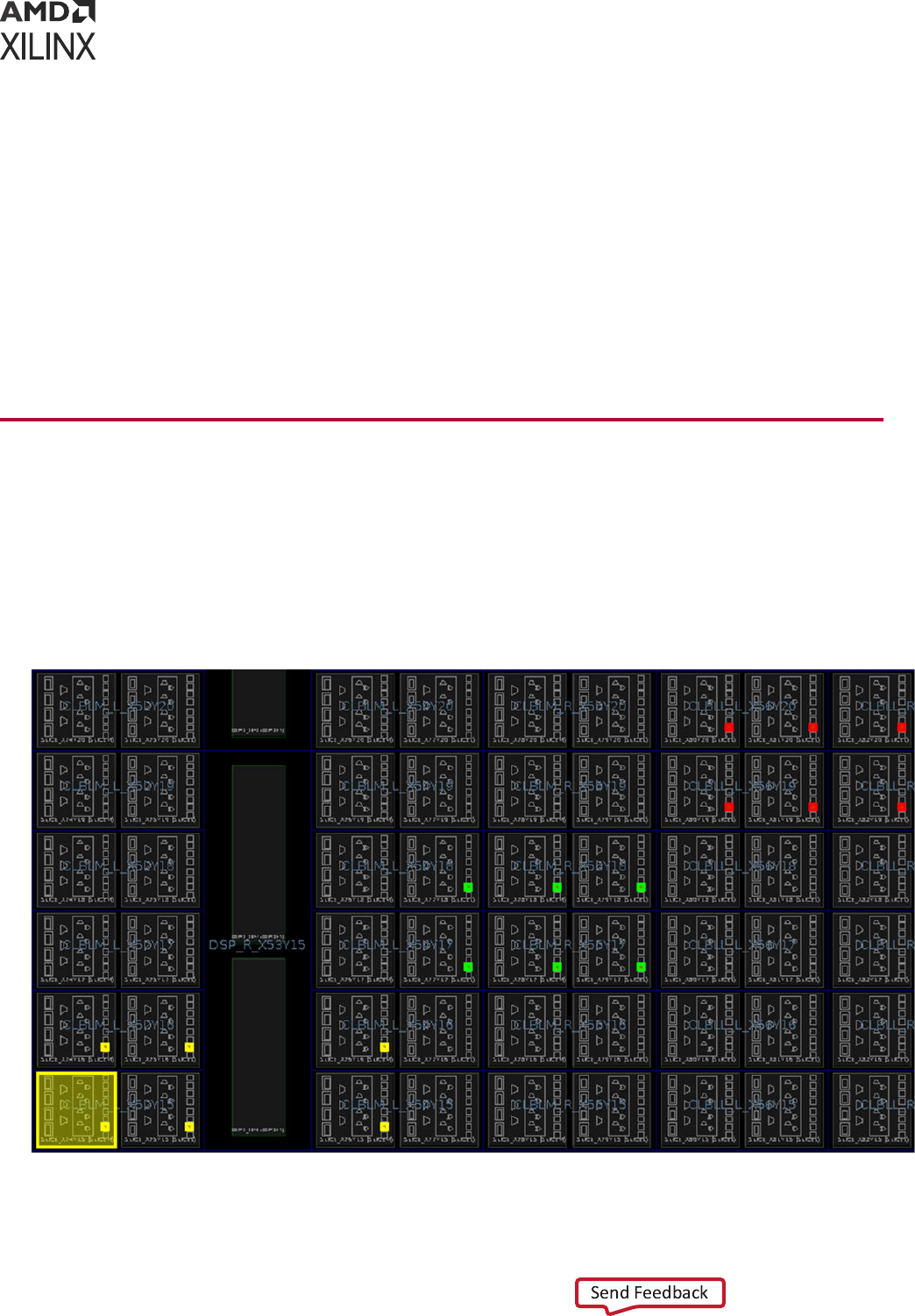

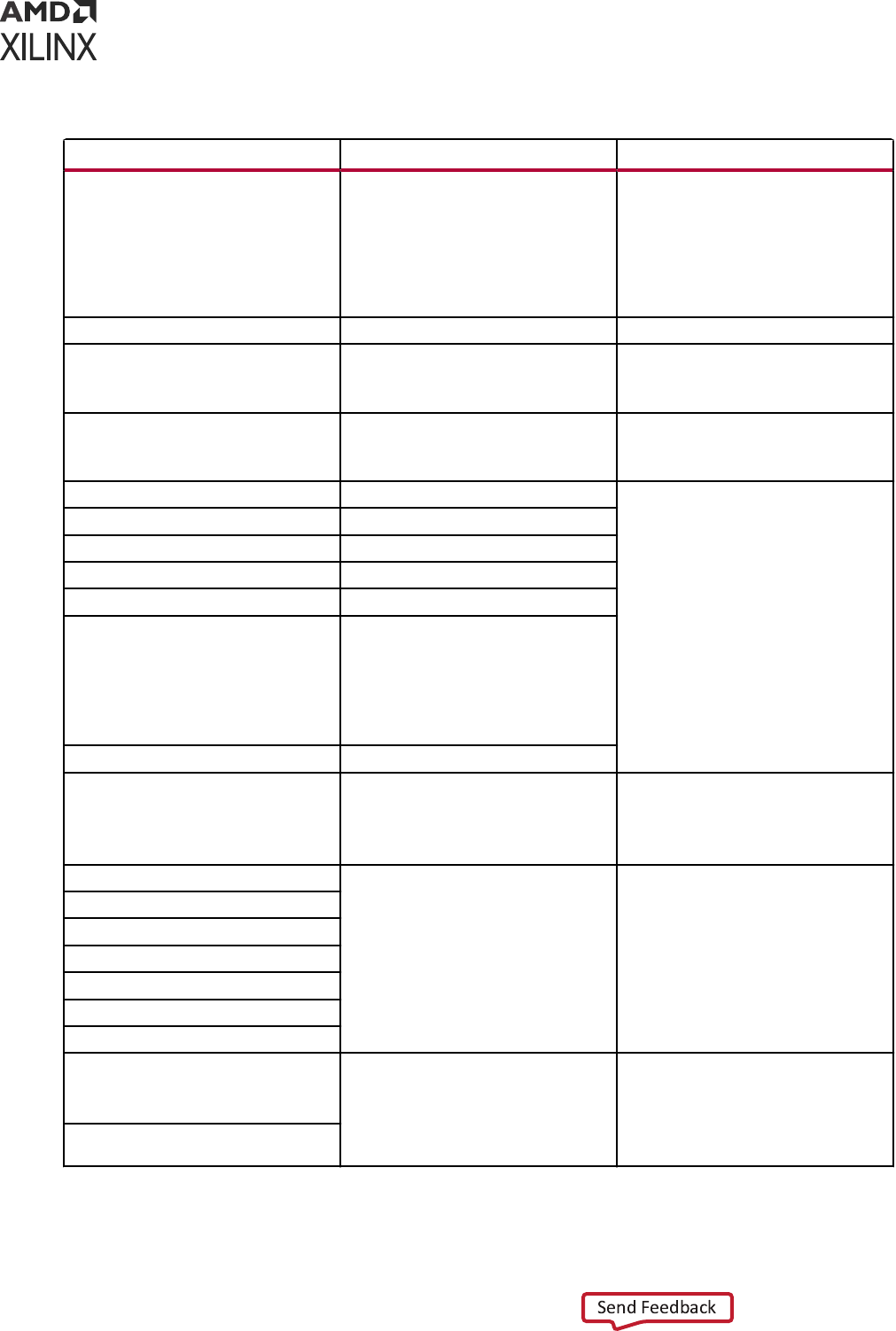

For example, the following gure shows that one of the IP cores in the project comes with an

XDC le.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 14

Figure 3: XDC Files in the IP Sources

By default, IP XDC les are read in before the user XDC les. Processing it in this way allows an

IP to create a clock object that can be referenced in the XDC. It also allows you to overwrite

physical constraints set by an IP core because the user constraints are evaluated aer the IP.

There is an excepon to this order for the IP cores that have a dependency on clock objects

being created by the user or by another IP (for example, get_clocks -of_objects

[get_ports clka]). In this case, the IP XDC is read aer the user les.

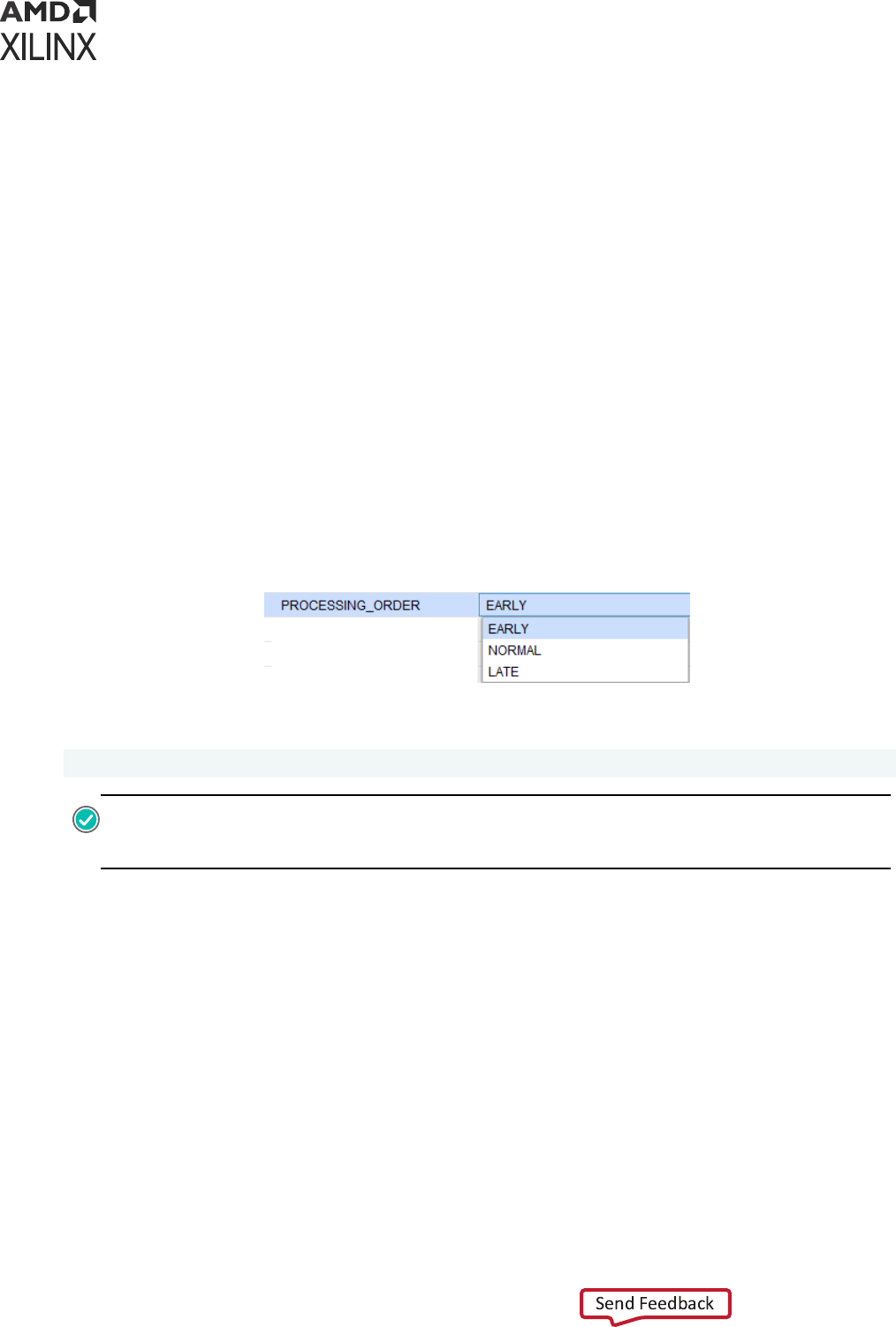

This behavior is controlled by the PROCESSING_ORDER property, set for each XDC le:

• EARLY: Files that must be read rst

• NORMAL: Default

• LATE: Files that must be read last

An IP XDC will have its PROCESSING_ORDER property set to either EARLY or LATE. No IP

delivers XDC les that belong to the NORMAL constraints group. For user XDC (or Tcl) les that

belong to the same PROCESSING_ORDER group, their relave order displayed in the Vivado IDE

determines their read sequence. The order within the group can be modied by moving the les

in the Vivado IDE constraints set, or by using the reorder_files command.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 15

For IP XDC les that belong to the same PROCESSING_ORDER group, the order is determined

by import or creaon sequence of the IP cores. This order cannot be changed aer the project

has been created.

Finally, the relave order between user groups and IP XDC PROCESSING_ORDER groups are as

follows:

1. User Constraints marked as EARLY

2. IP Constraints marked as EARLY (default)

3. User Constraints marked as NORMAL

4. IP Constraints marked as LATE (contain clock dependencies)

5. User Constraints marked as LATE

Note: IP XDC les that have their PROCESSING_ORDER set to LATE (in order to be processed aer the

user constraints) are named <IP_NAME>_clocks.xdc.

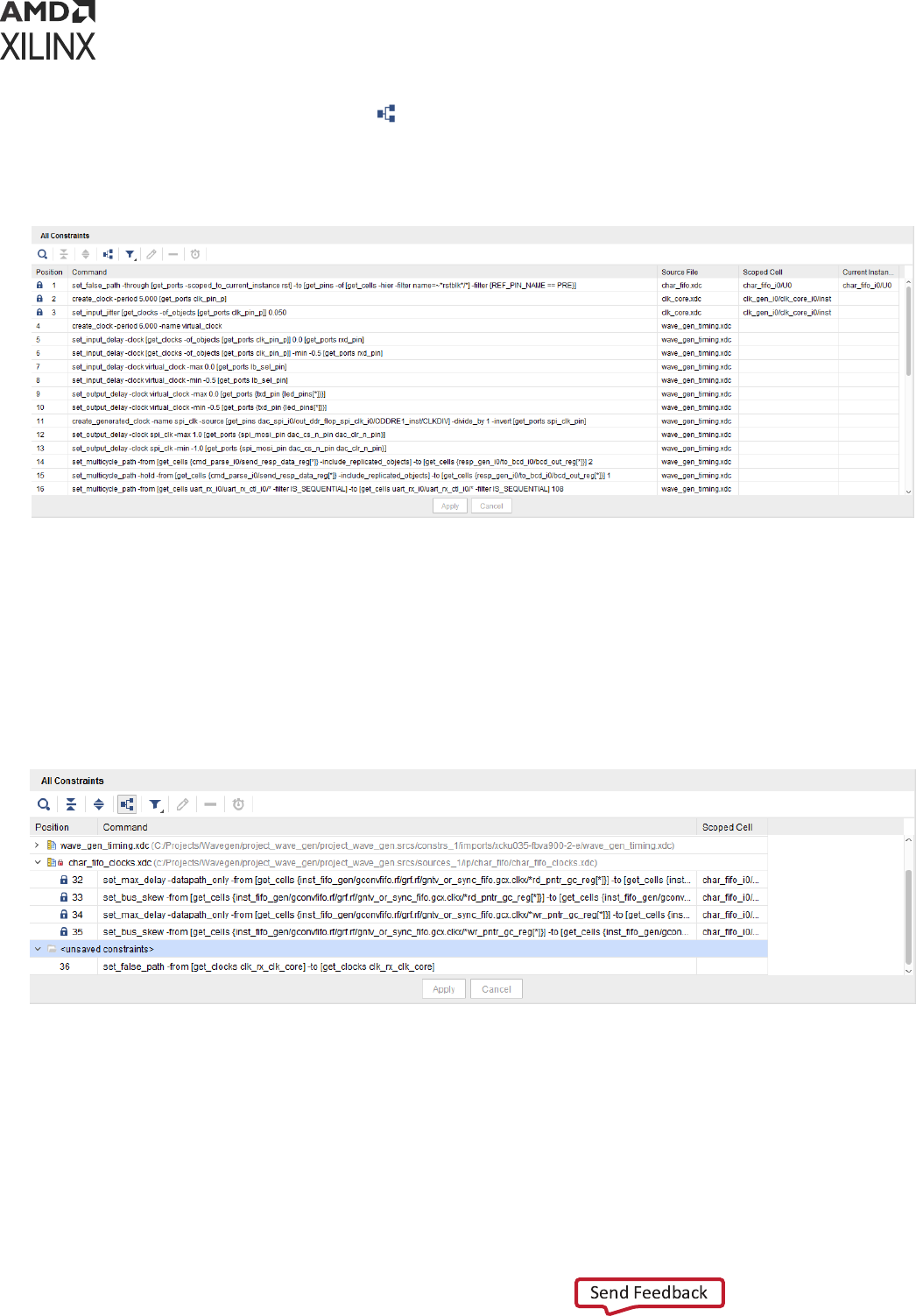

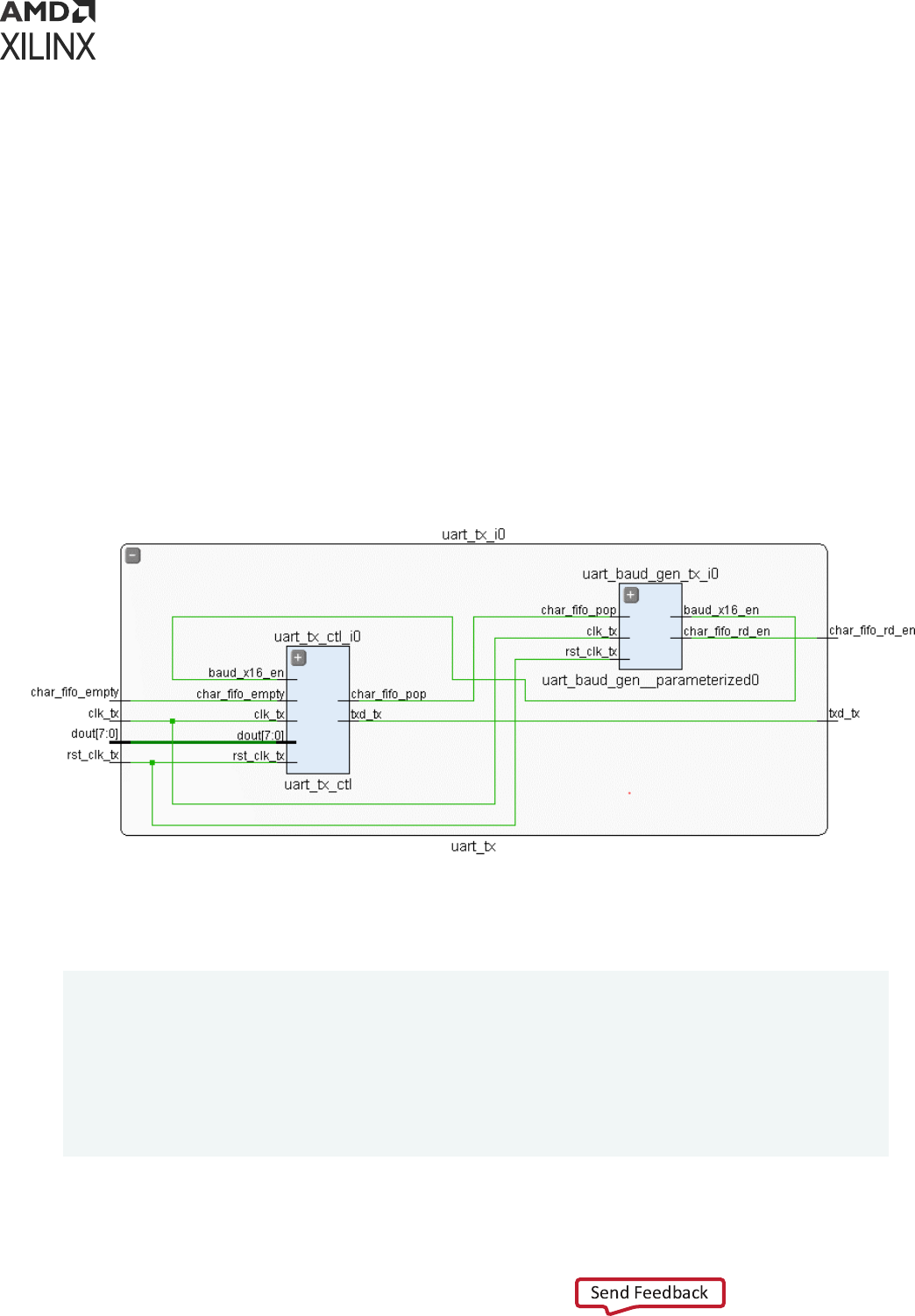

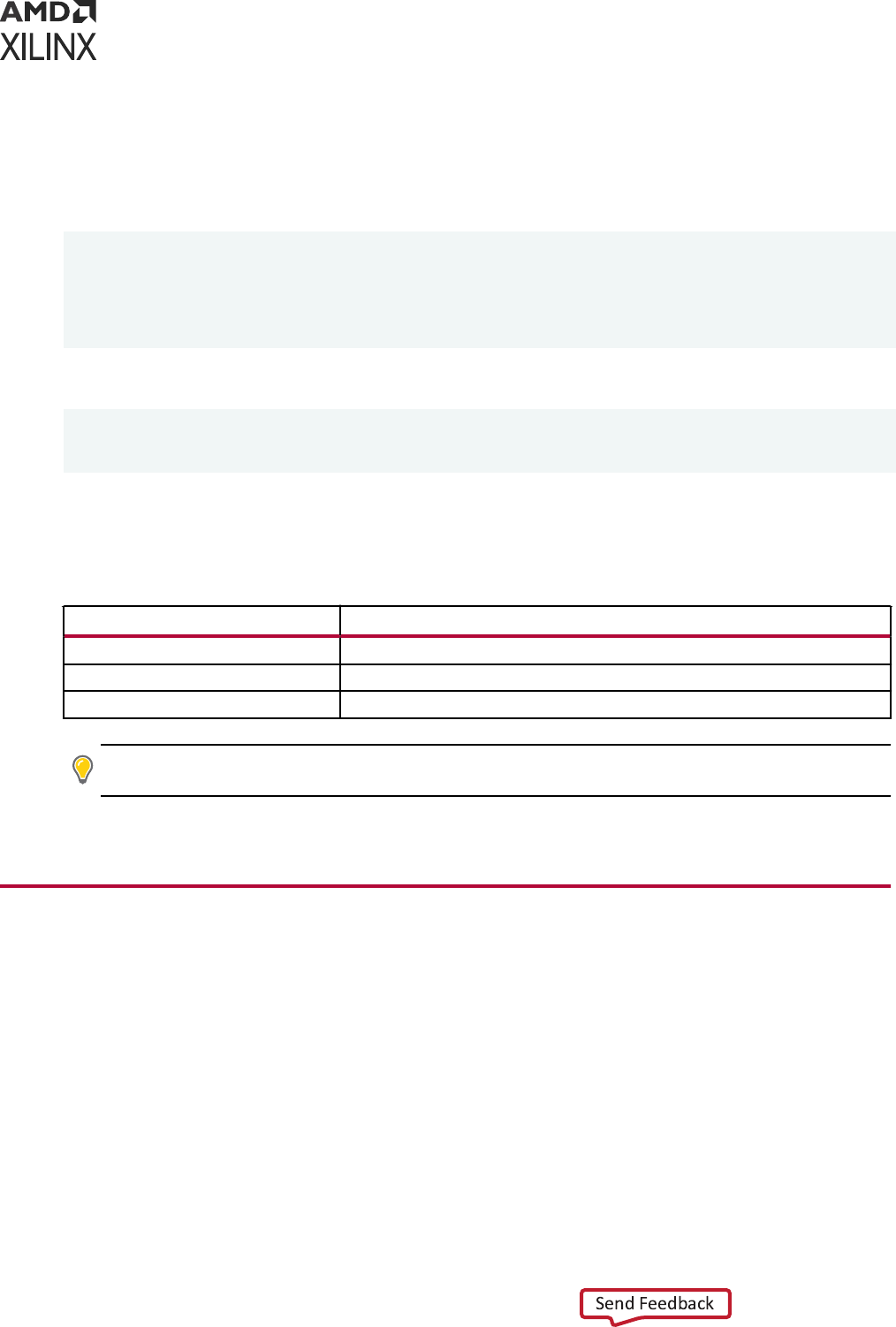

The following gure shows an example of how to set the PROCESSING_ORDER property:

Figure 4: Setting the XDC File PROCESSING_ORDER Example

The equivalent Tcl command is:

set_property PROCESSING_ORDER EARLY [get_files wave_gen_pins.xdc]

RECOMMENDED:

Use the

report_compile_order -constraints

command in the Tcl Console

to report the XDC les read sequence determined by the tool based the properes menoned above,

including IS_ENABLED, USED_IN_SYNTHESIS, and USED_IN_IMPLEMENTATION.

Note: When an IP is synthesized Out of Context, the IP provides, when needed, an _ooc.xdc le which

contains the default clock denion. The _ooc.xdc has the USED_IN property set to "synthesis

out_of_context implementaon" (order does not maer). During the Out Of Context synthesis, the _ooc

le is always processed before all other constraints.

Changing Read Order

To change the read order of an XDC le or unmanaged Tcl script in a constraints set:

1. In the Sources window, select the XDC le or Tcl script you want to move.

2. Drag and drop the le to the desired posion in the constraints set.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 16

For the example shown in Figure 2, the equivalent Tcl command is:

reorder_files -fileset constrs_1 -before [get_files wave_gen_timing.xdc] \

[get_files wave_gen_pins.xdc]

In Non-Project Mode, the sequence of the read_xdc or source commands determines the order

the constraint les are read.

If you use an IP core that comes with constraints, two groups of constraints are handled

automacally as follows:

• Constraints that do not depend on clocks are grouped in an XDC le with

PROCESSING_ORDER set to EARLY,

• Constraints that depend on clocks are grouped in an XDC le with PROCESSING_ORDER set

to LATE.

By default, user XDC les belong to the PROCESSING_ORDER NORMAL group. They are loaded

aer EARLY XDC les and before LATE XDC les. For each PROCESSING_ORDER group, IP

XDC les are loaded in the same sequence as how the IP cores are listed in the IP Sources

window. For example, the following gure shows one of the project IP cores that comes with an

XDC le.

Figure 5: XDC Files in the IP Sources

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 17

When you open your design, the log le shows that the IP XDC le was loaded last:

Parsing XDC File [C:/project_wave_gen_hdl.srcs/sources_1/ip/clk_core/

clk_core.xdc] for cell 'clk_gen_i0/clk_core_i0/inst'

Finished Parsing XDC File [C:/project_wave_gen_hdl.srcs/sources_1/ip/

clk_core/clk_core.xdc] for cell 'clk_gen_i0/clk_core_i0/inst'

Parsing XDC File [C:/project_wave_gen_hdl.srcs/sources_1/ip/char_fifo/

char_fifo/char_fifo.xdc] for cell 'char_fifo_i0/U0'

Finished Parsing XDC File [C:/project_wave_gen_hdl.srcs/sources_1/ip/

char_fifo/char_fifo/char_fifo.xdc] for cell 'char_fifo_i0/U0'

Parsing XDC File [C:/project_wave_gen_hdl.srcs/constrs_1/imports/verilog/

wave_gen_timing.xdc] Finished Parsing XDC File [C:/

project_wave_gen_hdl.srcs/constrs_1/imports/verilog/wave_gen_timing.xdc]

Parsing XDC File [C:/project_wave_gen_hdl.srcs/sources_1/ip/char_fifo/

char_fifo/char_fifo_clocks.xdc

] for cell 'char_fifo_i0/U0'

Finished Parsing XDC File [C:/project_wave_gen_hdl.srcs/sources_1/ip/

char_fifo/char_fifo/char_fifo_clocks.xdc

] for cell 'char_fifo_i0/U0' Completed Processing XDC Constraints

Unlike with the User XDC les, you cannot directly change the read order of the IP XDC les that

belong to the same PROCESSING_ORDER group. If you must modify the order, do the following:

1. Disable the corresponding IP XDC les (IS_ENABLED set to false).

2. Copy their content.

3. Paste the content into one of the XDC les included in your constraints set.

4. Update the copied IP XDC commands with the full hierarchical netlist object path names

wherever needed. Doing so is required because the IP XDC constraints are wrien in such a

manner that they can be scoped to the IP instance.

5. Review the get_ports queries that are processed in a special way for scoped constraints. For

more informaon on XDC scoping, see Constraints Scoping.

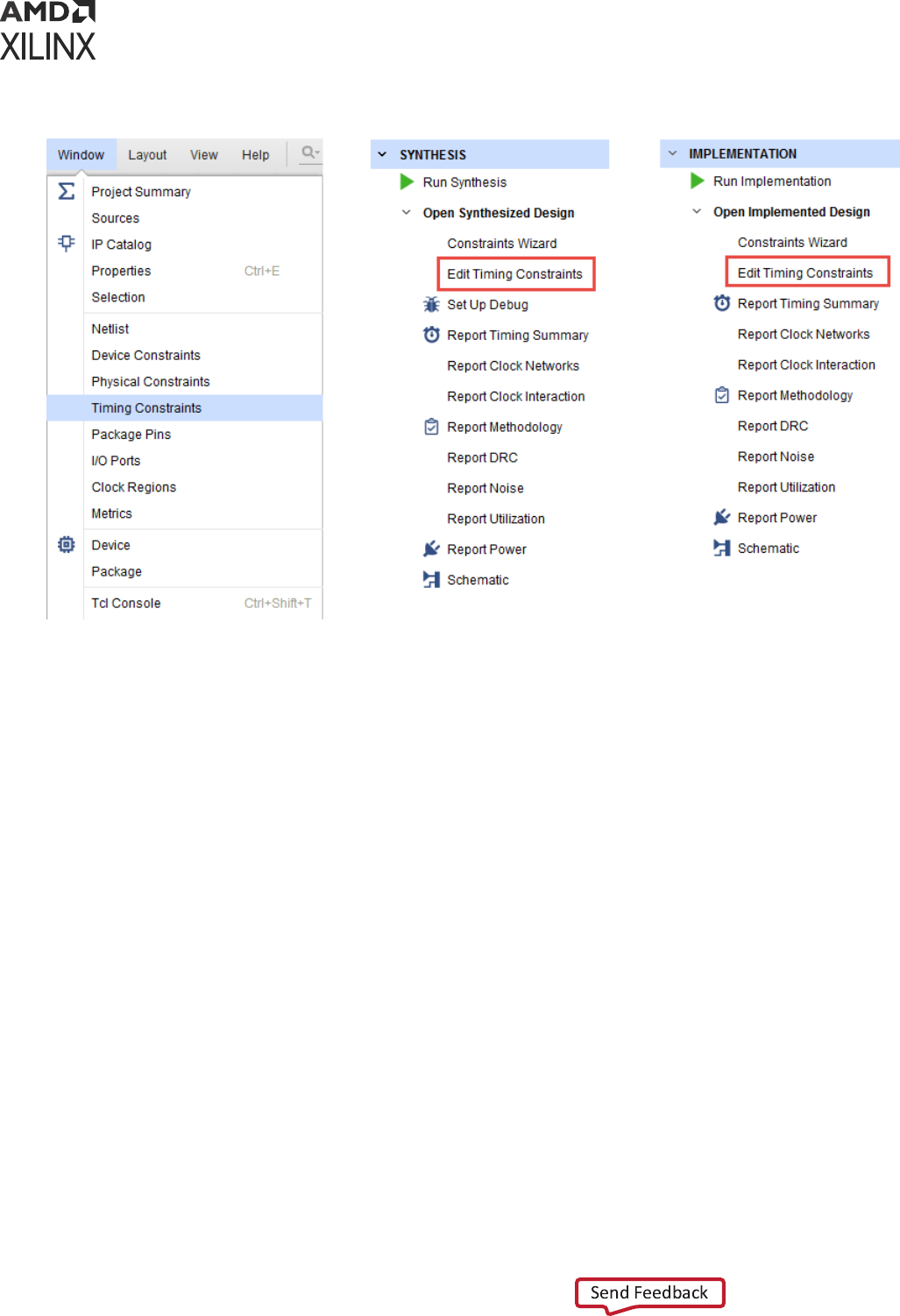

Entering Constraints

The Vivado IDE provides several ways to enter constraints. Unless you directly edit the XDC le

in a text editor, you must open a design database (elaborated, synthesized or implemented) in

order to access the constraints windows in the Vivado IDE.

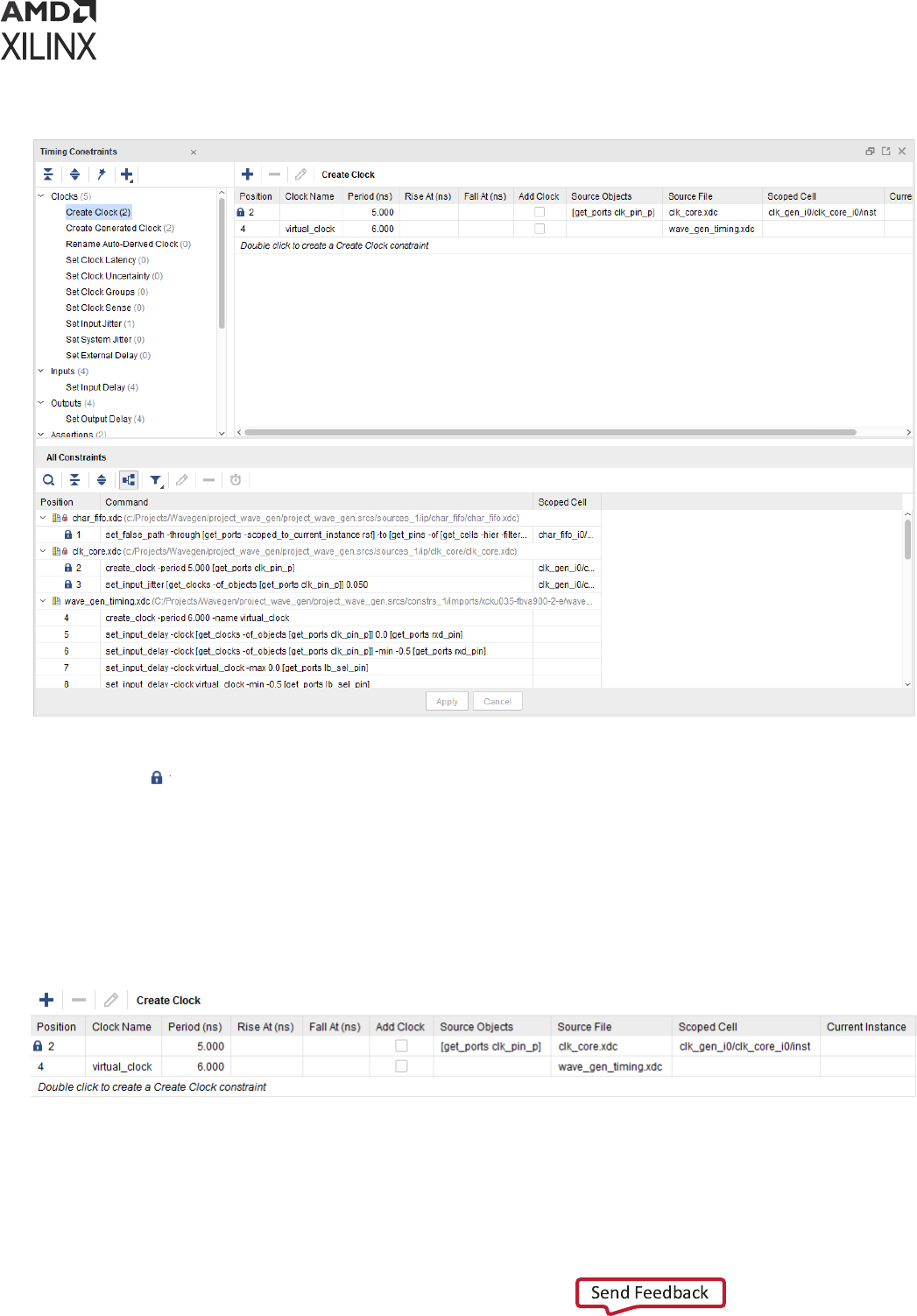

Saving Constraints in Memory

You must have a design in memory to validate your constraints during eding. When you edit a

constraint using the Vivado IDE user interface, the equivalent XDC command is issued in the Tcl

Console in order to apply it in memory. An edited ming constraint must be applied in memory

before it can be saved to the XDC le.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 18

Before you can run synthesis or implementaon, you must save the constraints in memory back

to an XDC le that belongs to the project. The Vivado IDE prompts you to save your constraints

whenever necessary.

Do one of the following to save your constraints manually:

• Click Save Constraints.

• Select File → Constraints → Save.

Note: When you save the in-memory constraints, a dialog box opens to remind you that this could cause

the synthesis and implementaon to go out of date. Select the Remember Preference check box on this

dialog box to disable future instances of this warning.

When you run these commands, Vivado does the following:

• Saves all new constraints to the XDC le marked target in the constraints set associated with

your design.

• Saves all edited constraints back to the XDC le from which they originated.

Note: The constraints management system preserves the original XDC les format as much as possible.

Constraints Editing Flow Options

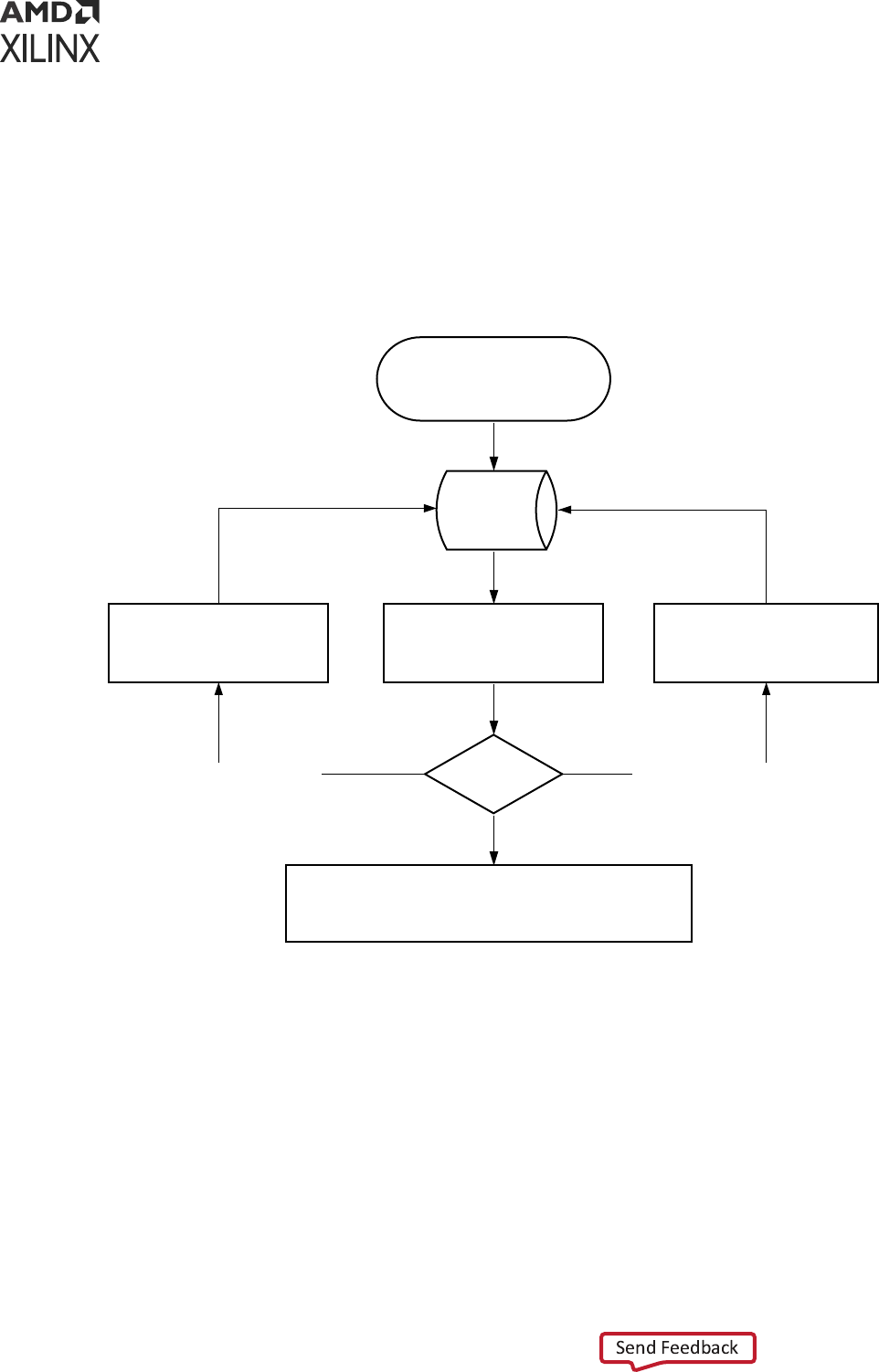

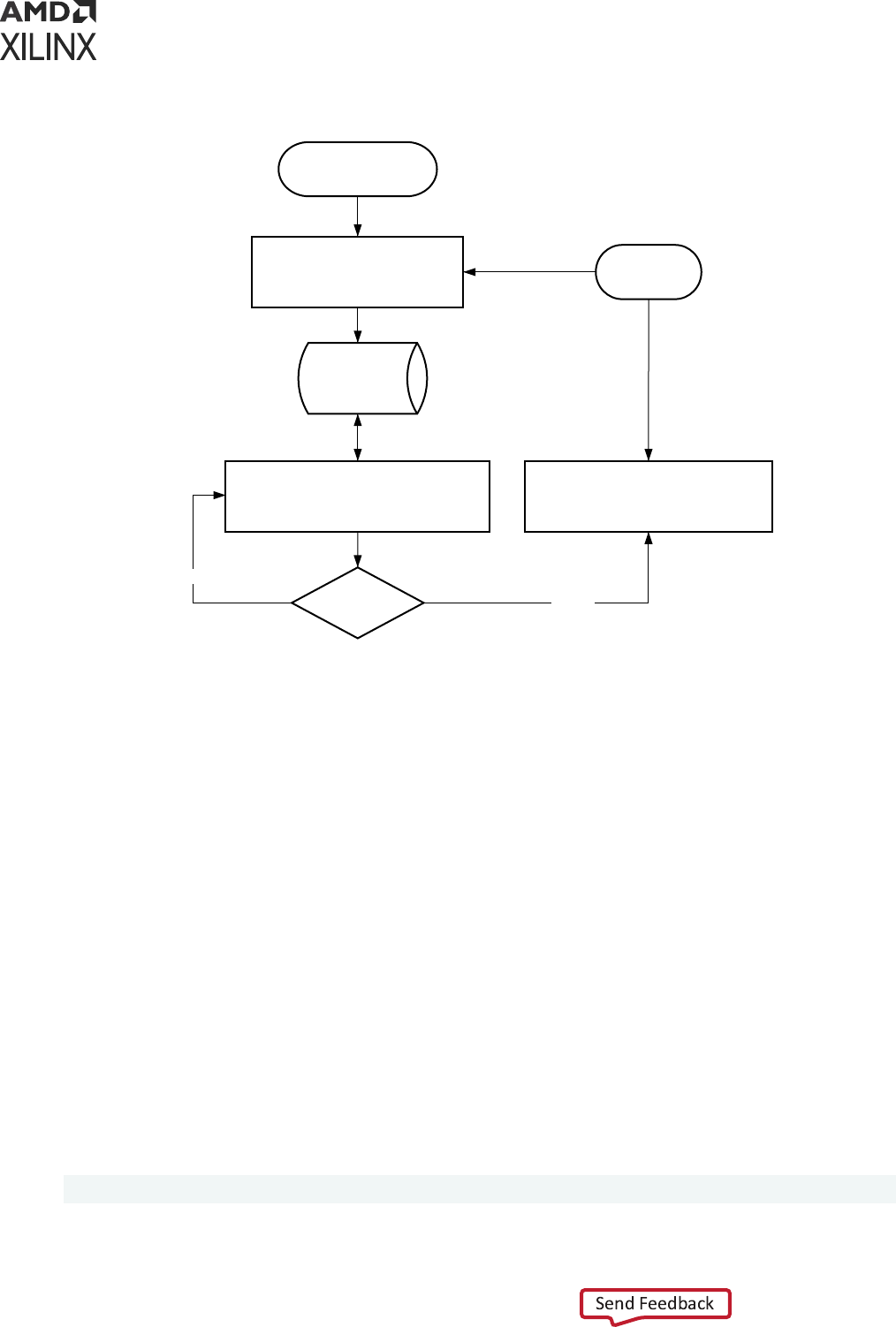

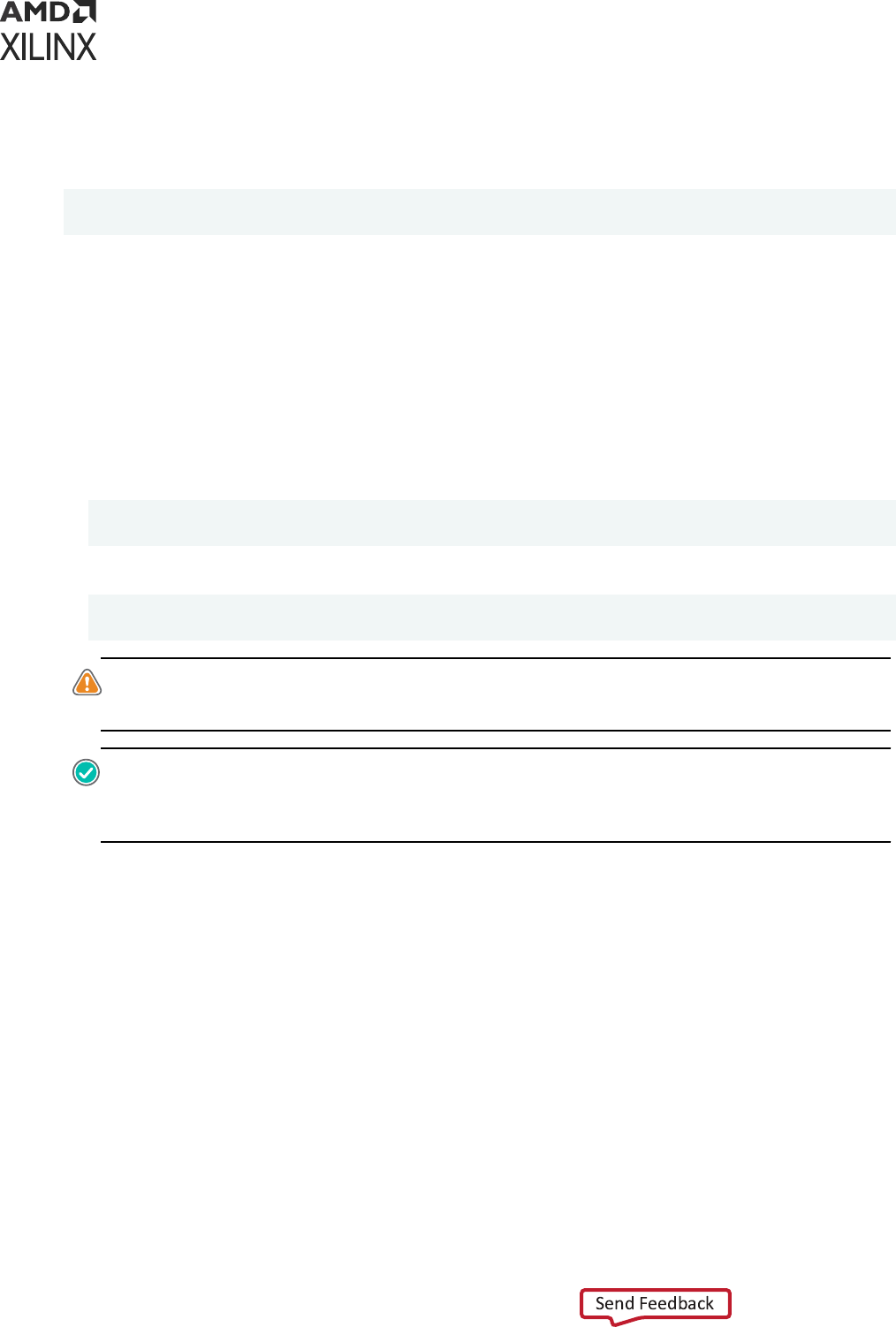

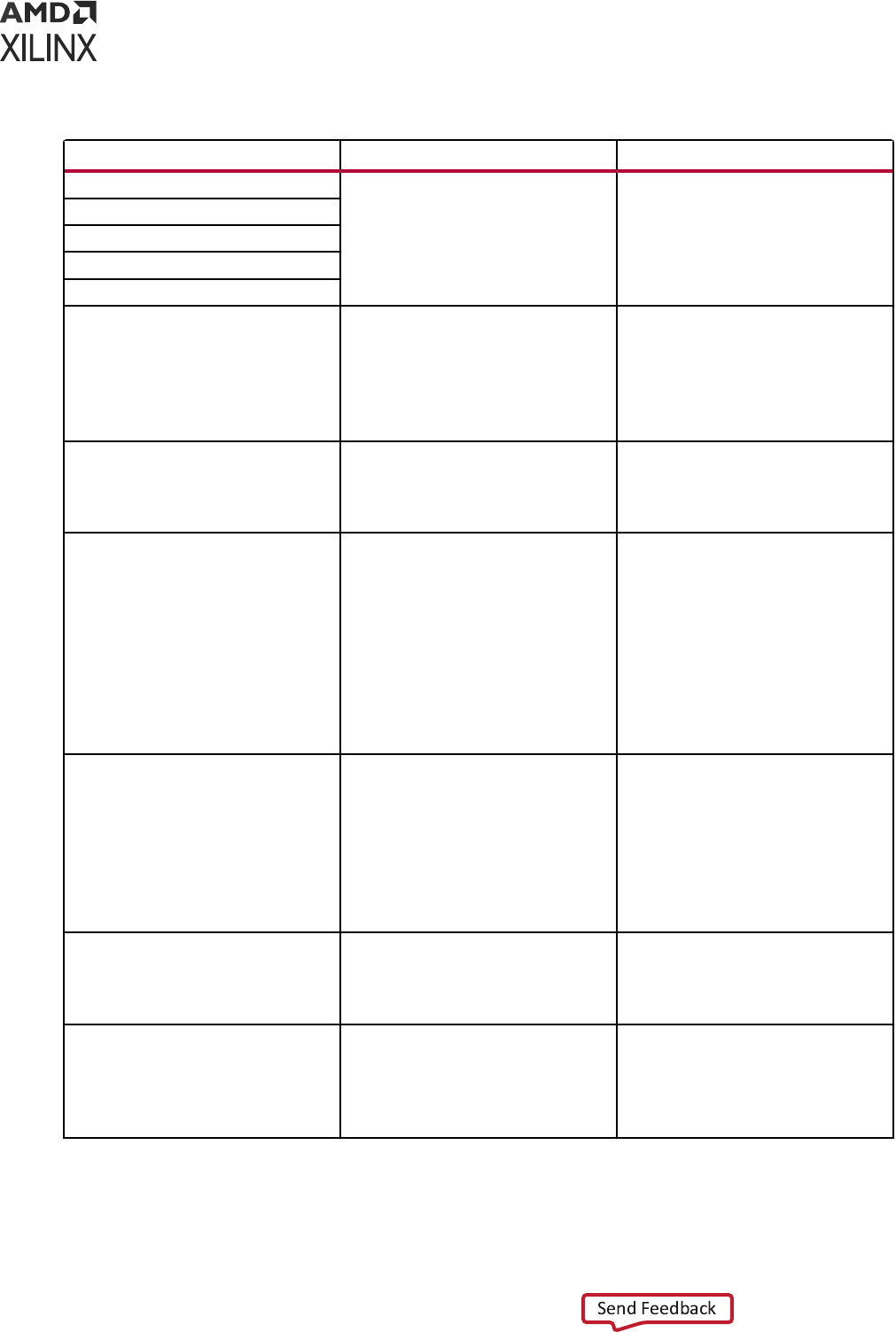

Figure 6 shows the recommended ow opons. Do not use both opons at the same me.

Mixing these opons might cause you to lose constraints. The recommended ow opons are:

• User Interface Opon

• Hand Edit Opon

User Interface Option

Because the Vivado IDE manages your constraints, you must not edit your XDC les at the same

me. When the Vivado IDE saves the memory content, the following occurs:

• The modied constraints replace the original constraints in their original le.

• The new constraints are appended to the le marked as target.

• All manual edits in the XDC les are overwrien.

Hand Edit Option

When you use the Hand Edit opon, you are in charge of eding and maintaining the XDC les.

While you will probably use the Tcl Console to verify the syntax of some constraints, you must

discard the changes made in memory when closing or reloading your design.

In case of a conict when saving the constraints, you are prompted to choose one of the

following:

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 19

• Discarding the changes made in memory

• Saving the changes in a new le

• Overwring the XDC les

Constraints creaon is iterave. You can use IDE editors in some cases, and hand edit the

constraint les in others.

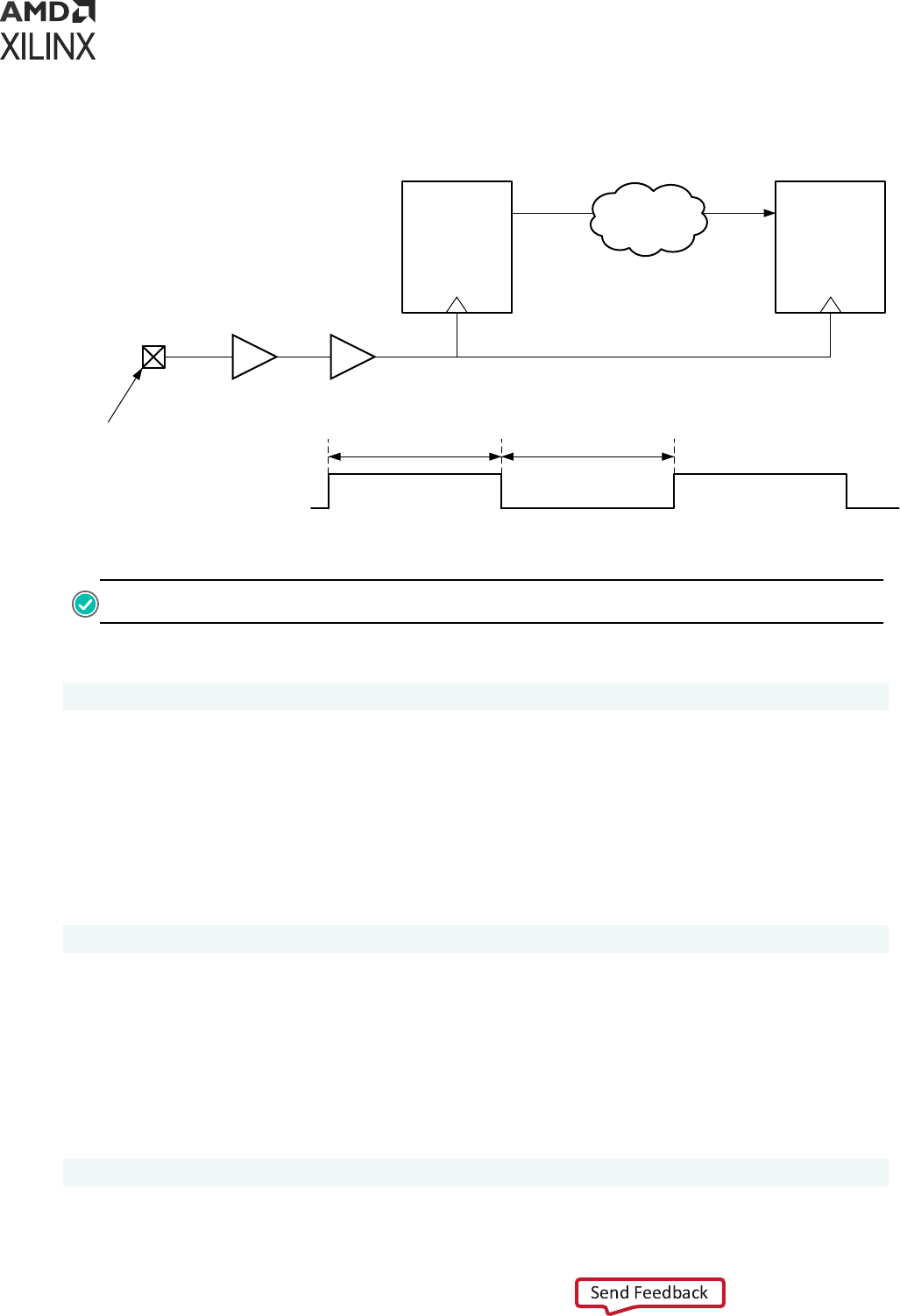

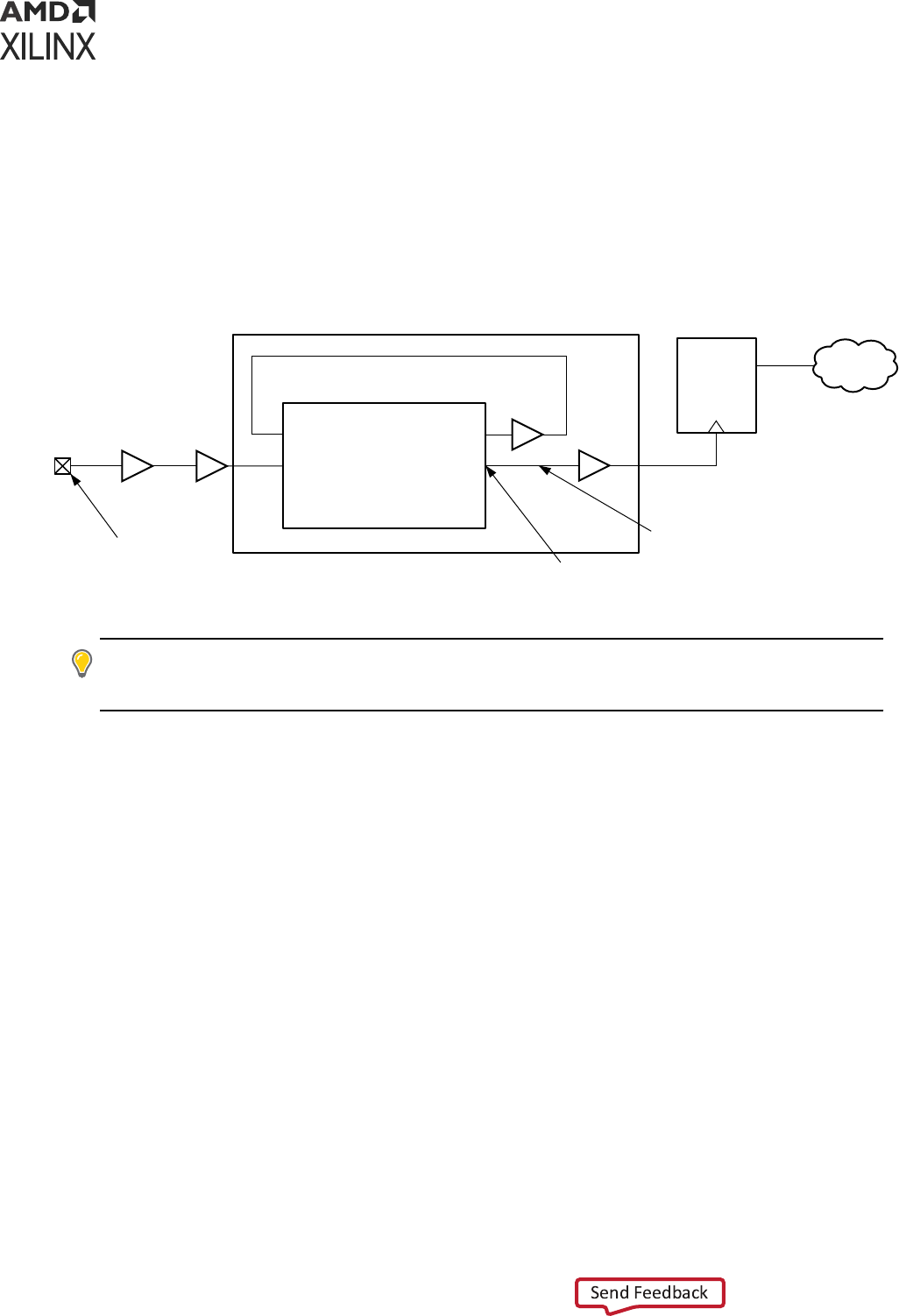

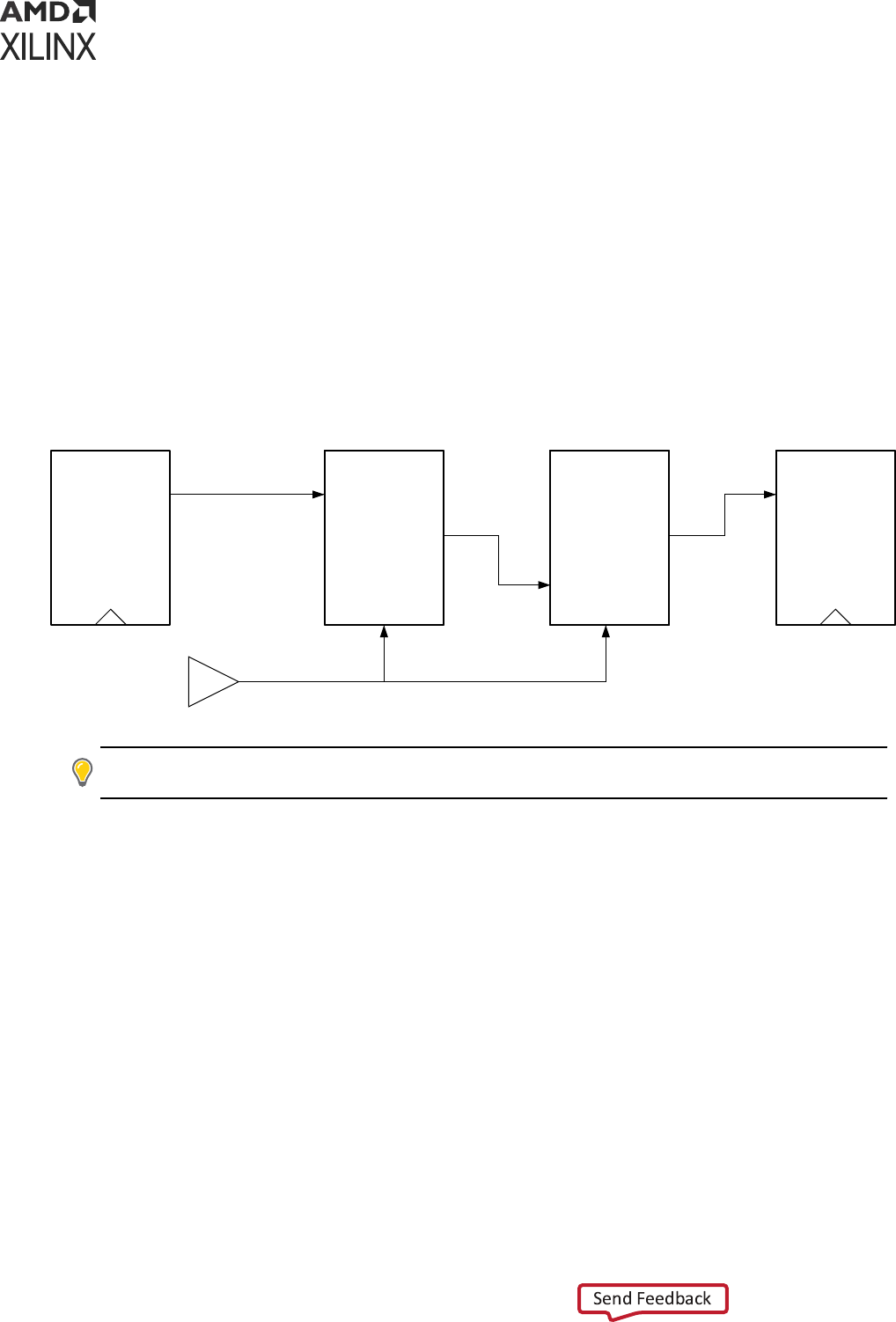

Figure 6: Constraints Editing Flow

Load your design in memory

Vivado

Database

Analyze your design

schematics/Device/

Reports)

Need more

constraints

?

Use Vivado IDE editors

(Device/Physical/Timing/

Others...) or Tcl Console

1. Edit XDC files in Text Editor

2. Save your XDC files

3. Reload your design

Close your design / Run compilation:

GUI Option: save changes to XDC file(s) (new or existing)

Hand Edit Option: do nothing (or discard any changes)

NO

YES (GUI Option) YES (Hand Edit Option)

X12983

Within each iteraon described in the previous gure, do not use both opons at the same me.

If you switch between the two opons, you must rst save your constraints or reload your

design, to ensure that the constraints in memory are properly synchronized with the XDC les.

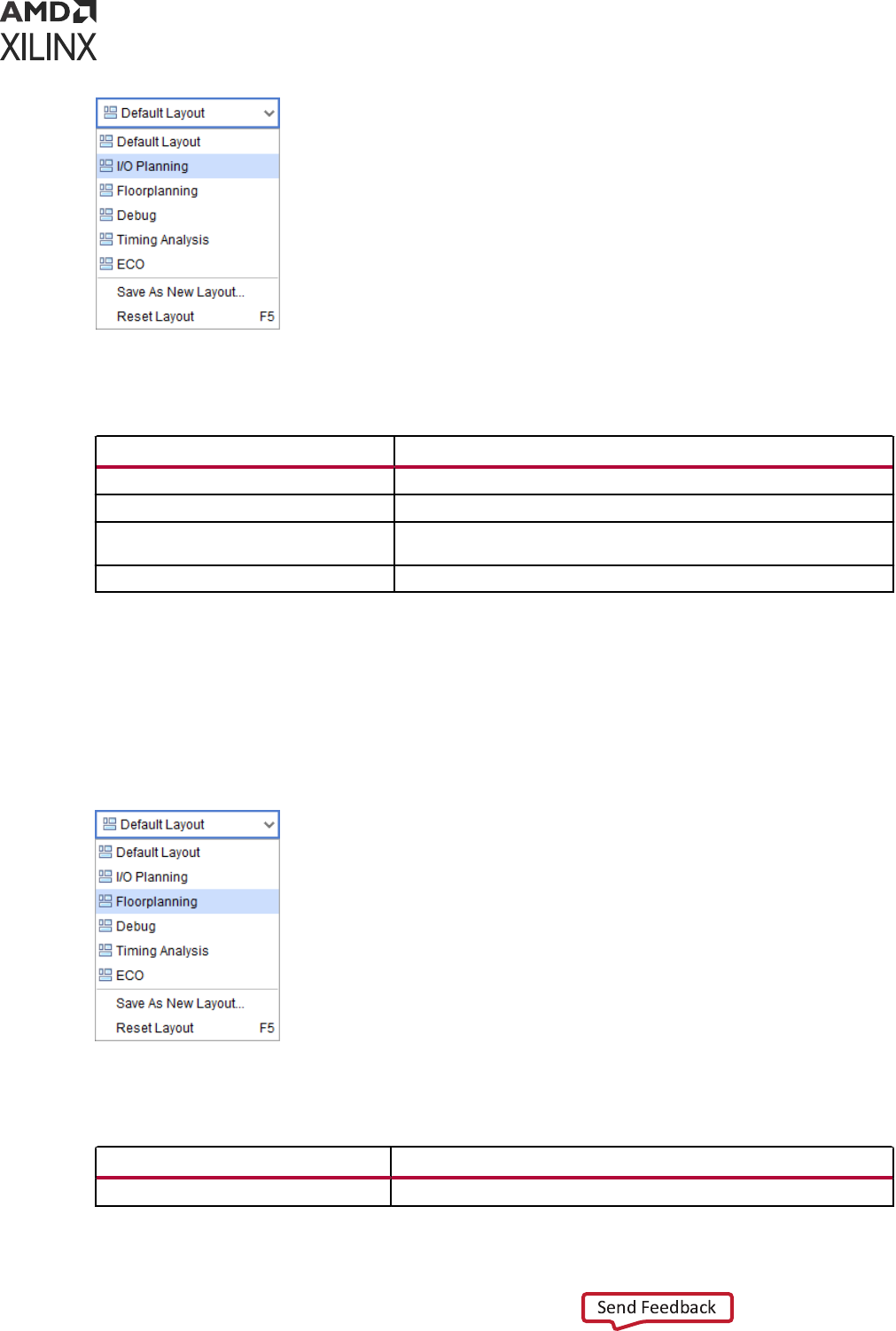

Pin Assignment

To create and edit exisng top-level ports placement when using the RTL Analysis, Synthesis, or

Implementaon views:

1. Select the I/O Planning pre-congured layout.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 20

2. Open the windows shown in the following table:

Table 3: Creating and Editing Existing Top-Level Ports Placement

Window Function

Device View and edit the location of the ports on the device floorplan.

Package View and edit the location of the ports on the device package.

I/O Ports Select a port, drag and drop it to a location on the Device or Package

view, as well as review current assignment and properties of each port.

Package Pins View the resource utilization in each I/O bank.

For more informaon on Pin Assignment, see this link in the Vivado Design Suite User Guide: I/O

and Clock Planning (UG899).

Floorplanning

To create and edit Pblocks when using the RTL Analysis, Synthesis, or Implementaon views:

1. Select the Floorplanning pre-congured layout.

2. Open the windows shown in the following table.

Table 4:

Creating and Editing Pblocks

Window Function

Netlist Select the cells to be assigned to a Pblock.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 21

Table 4: Creating and Editing Pblocks (cont'd)

Window Function

Physical Constraints Review the existing Pblocks and their properties.

Device Create or edit the shape and location of your Pblocks in the device.

To create cell placement constraints on a parcular BEL or SITE:

1. Select the cell in the Netlist view.

2. Drag and drop the cell to the target locaon in the Device view.

For more informaon on Floorplanning, see this link in the Vivado Design Suite User Guide: Design

Analysis and Closure Techniques (UG906).

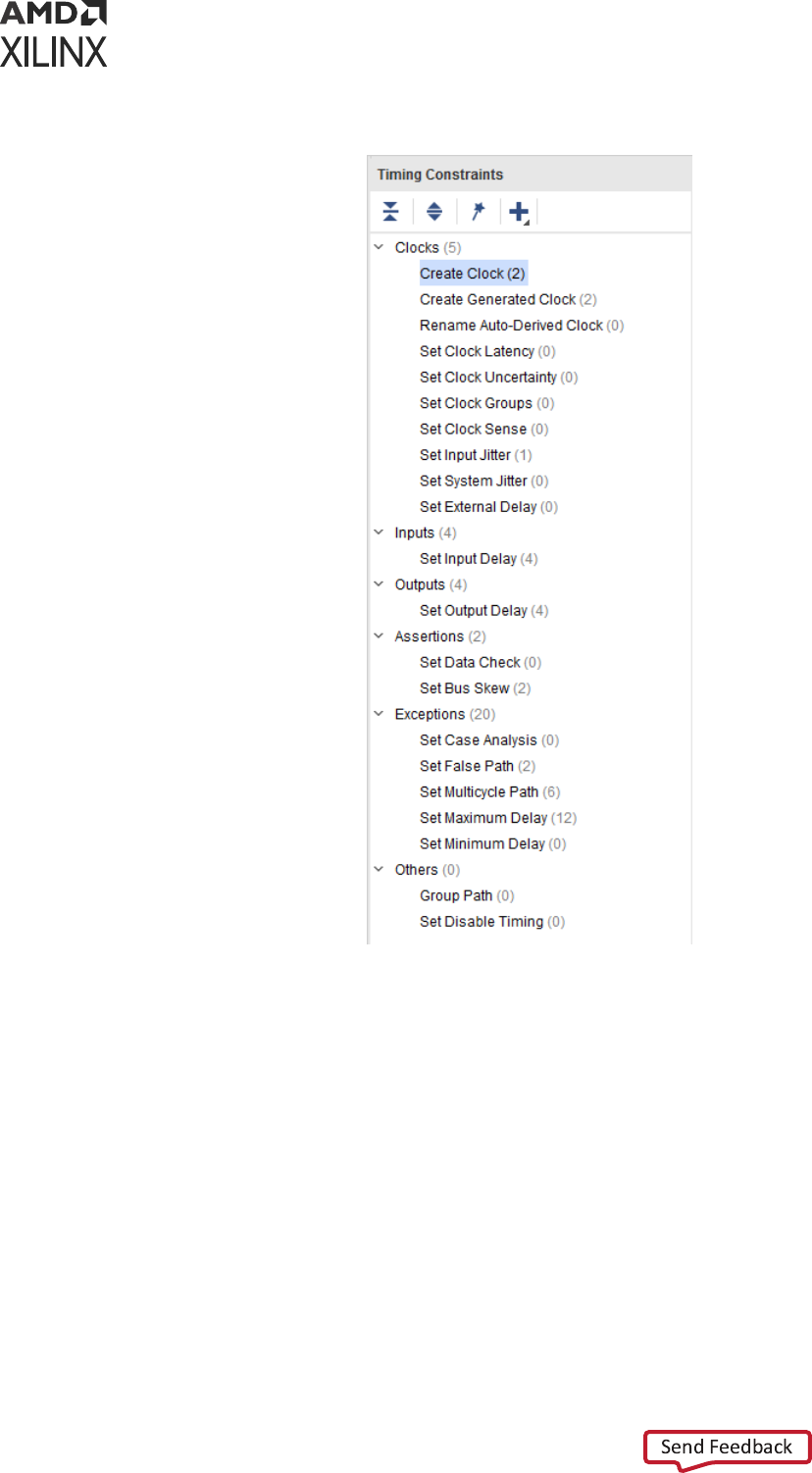

Timing Constraints Wizard

The Timing Constraints Wizard idenes missing ming constraints on a synthesized or

implemented design. It analyzes the netlist, the clock nets connecvity, and the exisng ming

constraints in order to provide recommendaons as per the UltraFast Design Methodology Guide

for Xilinx FPGAs and SoCs (UG949). Three categories of constraints are covered by the following

11 pages of the wizard, followed by a summary. The following steps are included:

• Clocks

○ Primary clocks

○ Generated clocks

○ Forwarded clocks

○ External feedback delays

• Input and output ports

○ Input delays

○ Output delays

○ Combinatorial delays

• Clock domain crossing

○ Physically exclusive clock groups

○ Logically exclusive clock groups with no interacon

○ Logically exclusive clock groups with interacon

○ Asynchronous clock domain crossings

• Constraints summary

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 22

During each step, you can accept the recommended constraints or modify the list by checking or

unchecking each of the proposed constraints. However, unchecking recommended constraints

early in the wizard can prevent the idencaon of other missing constraints in subsequent

steps. For example, if you decide to skip the creaon of a clock, the wizard will not idenfy and

recommend any constraints that refer to this clock or its auto-derived clocks.

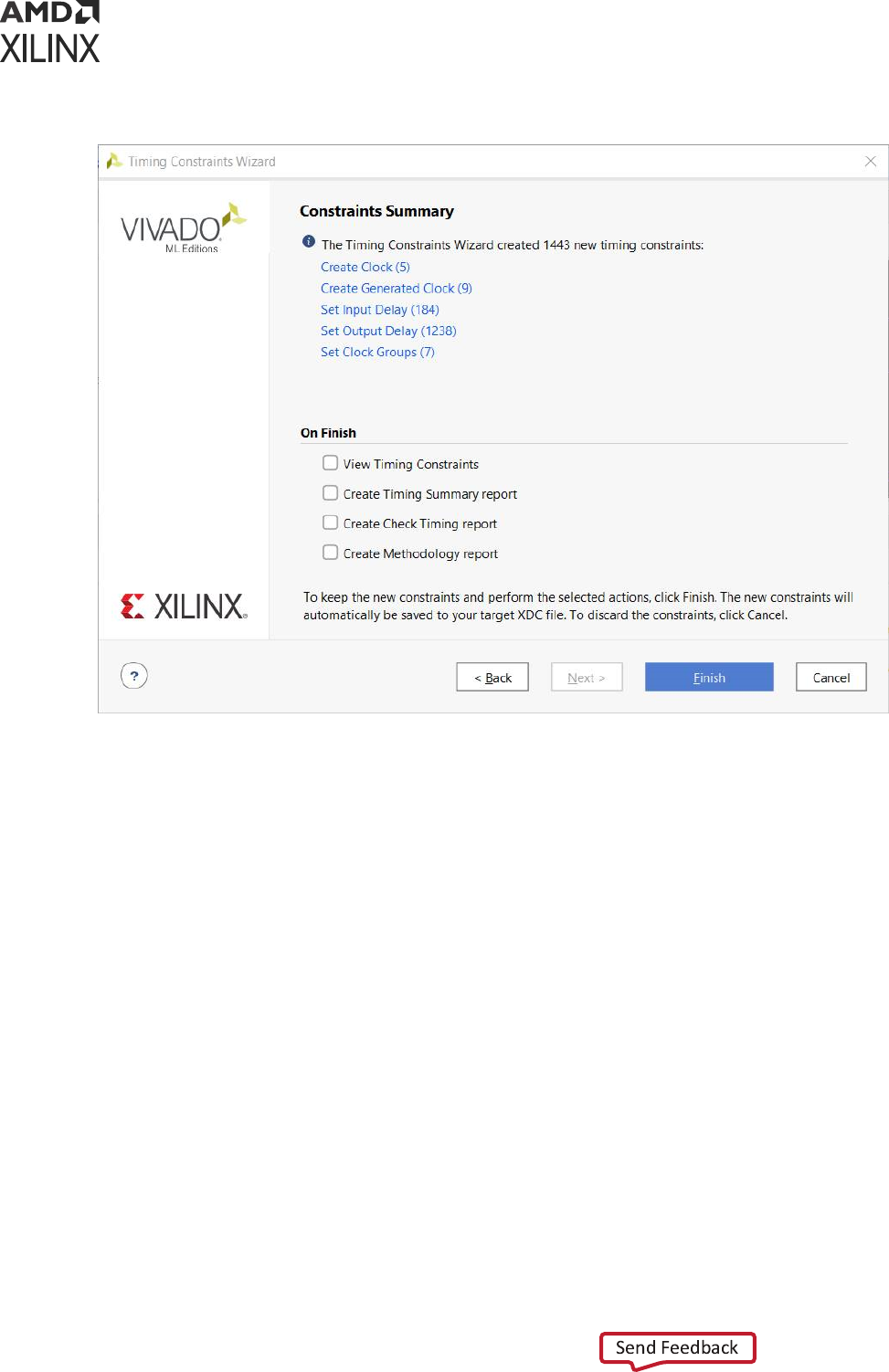

The nal page of the wizard provides a summary of the constraints that will be created. You can

click on each individual hyperlink to see the constraints details, or visualize the new constraints in

the Timing Constraints window aer exing the wizard.

You can also choose to generate the following recommended reports upon clicking Finish to

verify that the design is completely and properly constrained:

• Create Timing Summary report: Timing slack is reported with the new constraints, in addion

to a check_ming report. Timing violaons will likely display if the period or I/O delay

constraints that you entered are too dicult.

• Create Check Timing report: This report idenes missing or inappropriate constraints by

running the check_timing command.

• Create DRC Report using only Timing Checks: This report runs the Timing DRCs.

IMPORTANT!

The newly added constraints are automacally saved to the Target XDC le unless you click

Cancel. You can edit or delete the new constraints in the Timing Constraints window aer exing the

wizard.

The Timing Constraint Wizard does not recommend a constraint if it introduces unsafe ming

analysis. Also, the wizard does not x inappropriate constraints that already existed when loading

the design in memory. Nevertheless, some invalid constraints might become valid aer creang

all the missing clocks when using Vivado Design Suite in project mode; for more details, see

Constraints Processing Order and Invalid Constraints, below. Also, aer using the wizard, if

check_timing or report_drc sll ag some constraints issues, it is usually due to a

constraint problem that already existed in the source XDC les. You must address these problems

directly instead of using the wizard to resolve them.

VIDEO:

For more informaon on the Vivado Timing Constraints Wizard, see Vivado Design Suite

QuickTake Video: Using the Vivado Timing Constraint Wizard.

Constraints Processing Order and Invalid Constraints

The Timing Constraints Wizard recommends missing constraints that dene clocks or refer to

clocks, which will be saved either at the end of the target XDC le in project mode, or at the end

of all constraints in other modes. For this reason, you must understand the following rules:

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 23

• Project mode: You must specify a target XDC le with its processing order set to NORMAL

before launching the Timing Constraints wizard. The target XDC le must belong to the

Constraints Set of the design open in memory and currently selected. The posion of the

target XDC le among the other XDC les maers because it species where the

recommended constraints will be applied and saved later. Also, the wizard tries to re-apply any

invalid constraint that belongs to XDC les parsed aer the target XDC le in order to provide

the most complete and accurate recommendaons.

For example, consider the netlist from synth_1 run open in memory with the Constraints Set

constr_1. This Constraints Set contains three XDC les in the sequence a.xdc, b.xdc, and

c.xdc. If you choose b.xdc as the target XDC le and each le contains an invalid

constraint, the Timing Constraints wizard applies the recommended clocks, then re-applies the

invalid constraints from c.xdc before proceeding to the next step and discovering other

missing constraints.

• Non-project or Design Check Point (DCP) modes: You cannot specify a target XDC le in

these modes, so the Timing Constraints wizard recommends and applies new constraints at

the last posion of the constraints sequence. This is equivalent to entering new constraints in

the Tcl Console or via the Timing Constraints window. In these modes, the wizard does not

aempt to re-apply invalid constraints. If the new constraints need to be applied earlier in the

overall constraints sequence in order to resolve constraints dependencies or precedence

issues, you must edit the constraints sequence manually.

Here is an example of how to manually edit constraints.

1. Create new constraints using the Vivado Design Suite.

2. Run one of the following commands:

write_xdc -exclude_physical timing_constraints.xdc write_xdc -type

timing timing_constraints.xdc

3. Edit timing_constraints.xdc to move the new constraints higher in the XDC le.

4. Save the le.

5. Run the following command:

reset_timing

6. Read the edited ming constraints le by typing:

read_xdc timing_constraints.xdc

You can review the updated ming constraints sequence using the Timing Constraints window.

Aer reviewing the new constraints, you can save the sequence into the DCP.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 24

Reporting Features Available When the Wizard is Open

When the Timing Constraints wizard is open, it prevents most acons in the Vivado IDE,

including using the Tcl Console or running ming analysis, in order to avoid database

discrepancies. The wizard window is always in front of the other Vivado IDE windows. If you

need to access the Vivado IDE menus or windows, you must move the wizard window to the

side.

Only the following features are available while the Timing Constraints wizard is open:

• Reporng and visualizing the clock networks: Most pages of the wizard have buons to

generate and access the clock network report to visualize the clock topologies, their source

point, and the shared segments for some of the clocks.

Refer to the Vivado Design Suite User Guide: Design Analysis and Closure Techniques (UG906) for

more details about the clock network report.

• Searching a name in source les or an object in the design in memory: The Find and Find In

Files dialog boxes are available from the Edit menu. You can use these dialog boxes to retrieve

some informaon about the design while entering the constraints in the wizard.

• Creang and Viewing schemacs: You can select design objects in the main Vivado IDE

window and visualize them in schemacs. All schemacs features are available. Only the last

step of the Timing Constraints wizard, Asynchronous Clock Domain Crossings, supports

convenient schemacs cross-probing when selecng one or several entries in the Timing

Paths tab.

Refer to the Vivado Design Suite User Guide: Using the Vivado IDE (UG893) for more info on

using schemacs.

• Visualizing constraints in memory with the Timing Constraints window: Each page of the

wizard includes a tab that shows the exisng constraints of the same type as recommended

by the step. This is convenient for quickly reviewing the details of constraints already created

in the XDC les. For a complete view of all ming constraints in memory, the Timing

Constraints window shows the full sequence of constraints, organized by XDC le, including

scoping informaon. It also displays the invalid constraints.

Constraints Editing within the Wizard

Each step of the wizard can recommend several constraints. Depending on the constraint, you

must take one of the following acons:

• Uncheck the constraints you do not want to create, using one of the following methods:

○ Remove each constraint from the list, one at a me, by unchecking each line.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 25

○ Remove all constraints by unchecking the upper le check box of the table.

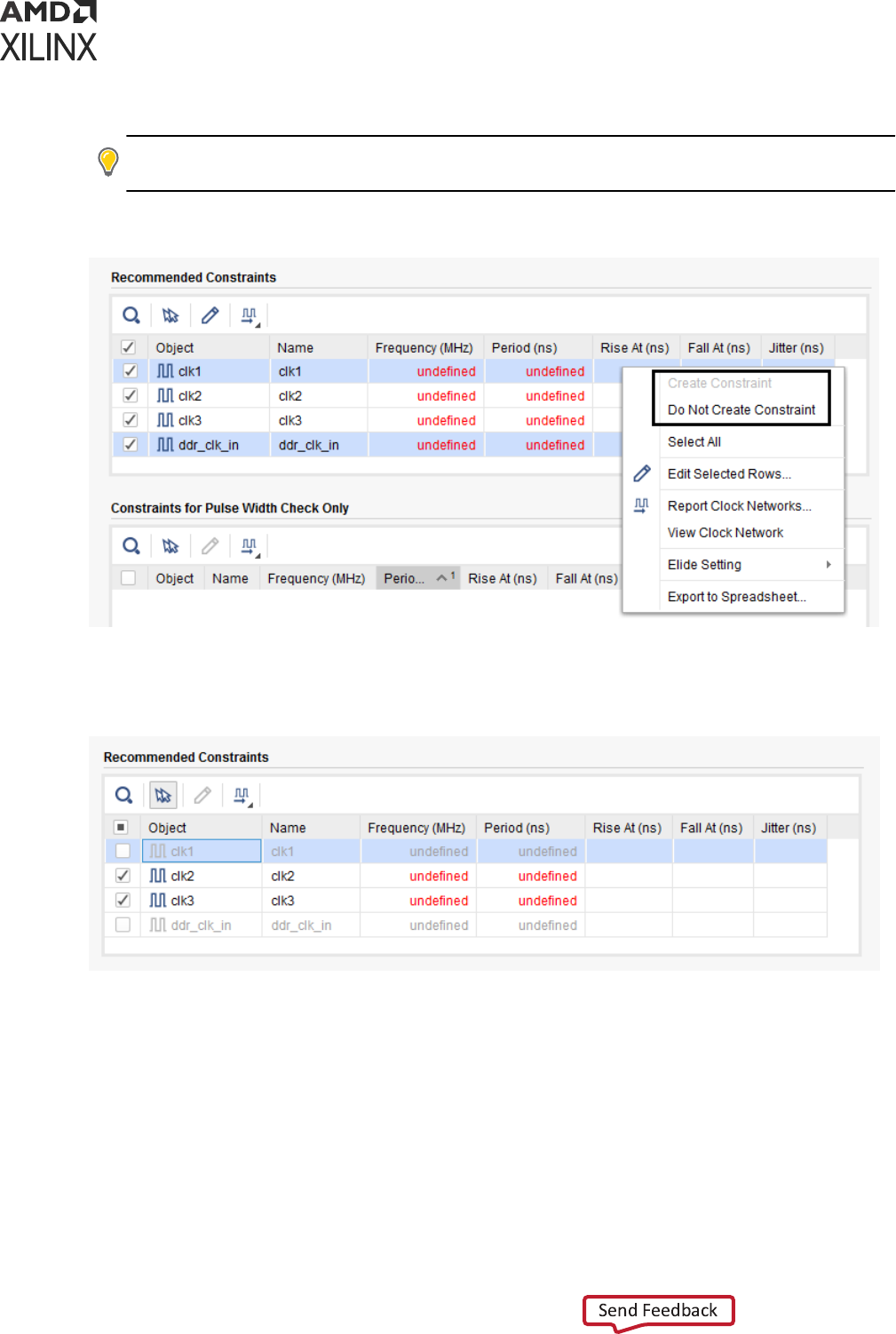

TIP: Alternavely, you can right-click the constraint, and select Do Not Create Constraint, as shown in

the following gure.

Figure 7: Skipping Recommended Constraints Using the Context Menu

In the following gure, clk1 and ddr_clk_in are unchecked and will be skipped.

Figure 8: Creating and Skipping Recommended Constraints

• Enter the missing values by clicking on the cells that show undened (for example, the

Frequency or Period value for clk2 and clk3 in the previous gure).

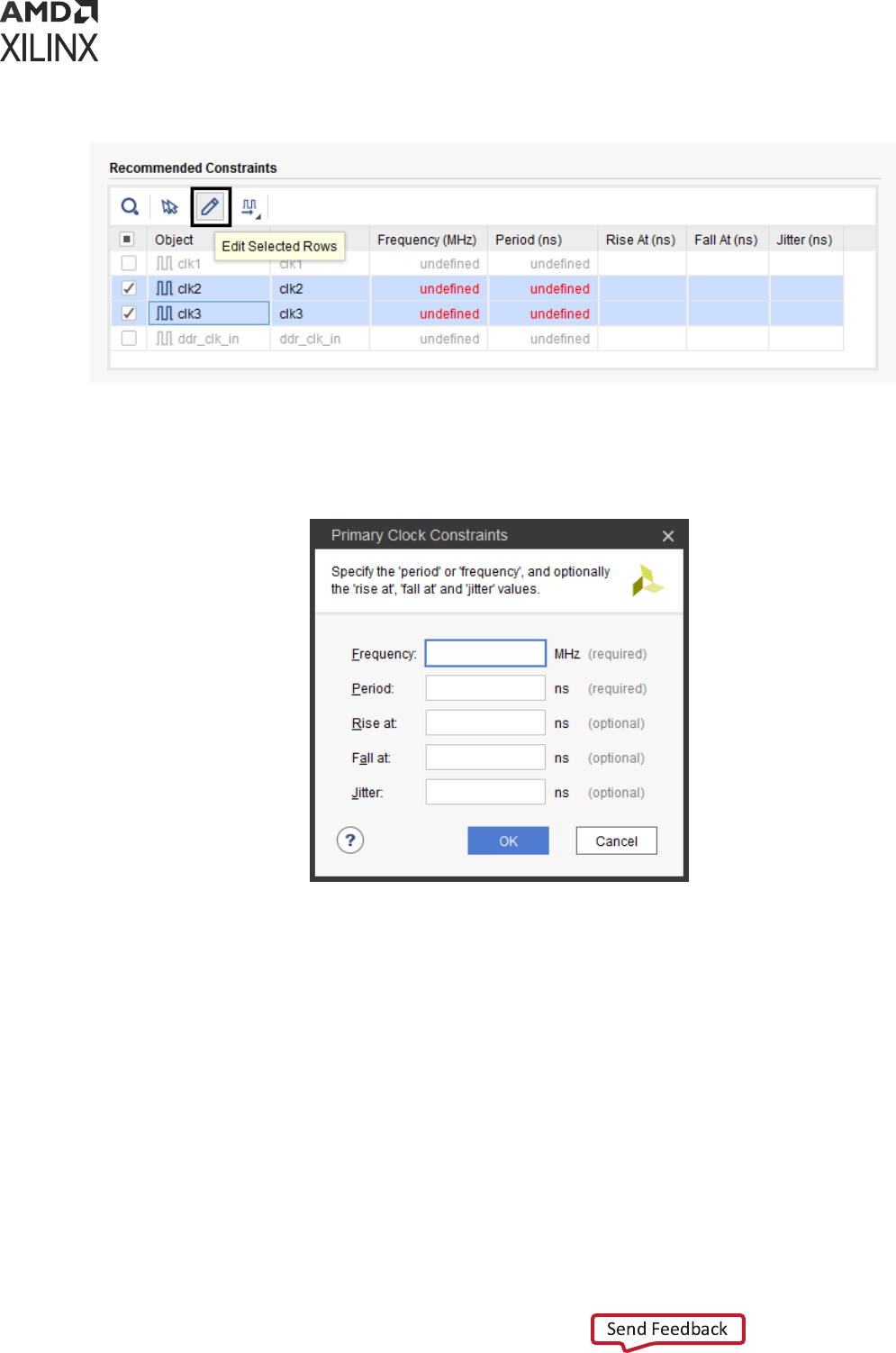

You can edit several constraints at the same me by selecng the corresponding rows and

clicking the Edit Selected Rows buon, as shown in the following gure.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 26

Figure 9: Editing Several Recommended Constraints

Next, ll out any required elds, such as Frequency and Period as shown in the following

gure:

Figure 10: Entering Parameters for Several Recommended Constraints

Eding mulple constraints at a me is parcularly helpful for input and output delay

constraints.

• Simply review the constraints if no acon is required.

When all the checked recommended constraints have been reviewed and completed, click Next

to proceed to the next page. Any entries that you missed prevent the wizard from moving to the

next step.

You can use the Back buon to revisit a page. If you edit any constraint on a previous page and

click Next, the wizard re-analyzes the design and recommends new constraints accordingly. In

most cases, the previously recommended constraints not aected by the change are reinstated. If

you only view a previous page without modifying any of its recommended constraints, the wizard

does not re-run any analysis, which usually saves runme.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 27

IMPORTANT! You cannot use the Timing Constraints wizard to edit exisng ming constraints. Instead,

you must use the Timing Constraints window.

Constraints Recommended by the Wizard

Primary Clocks

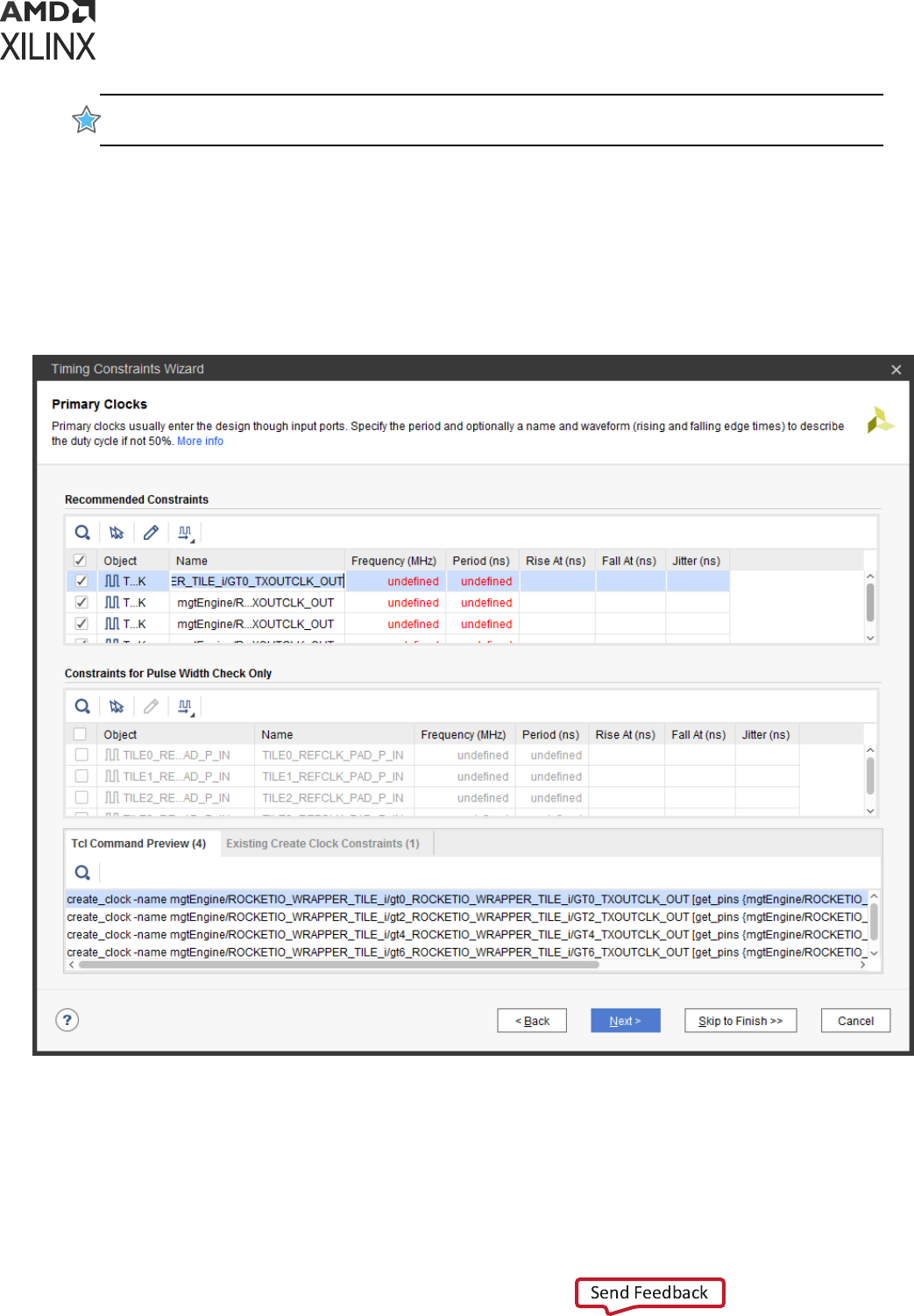

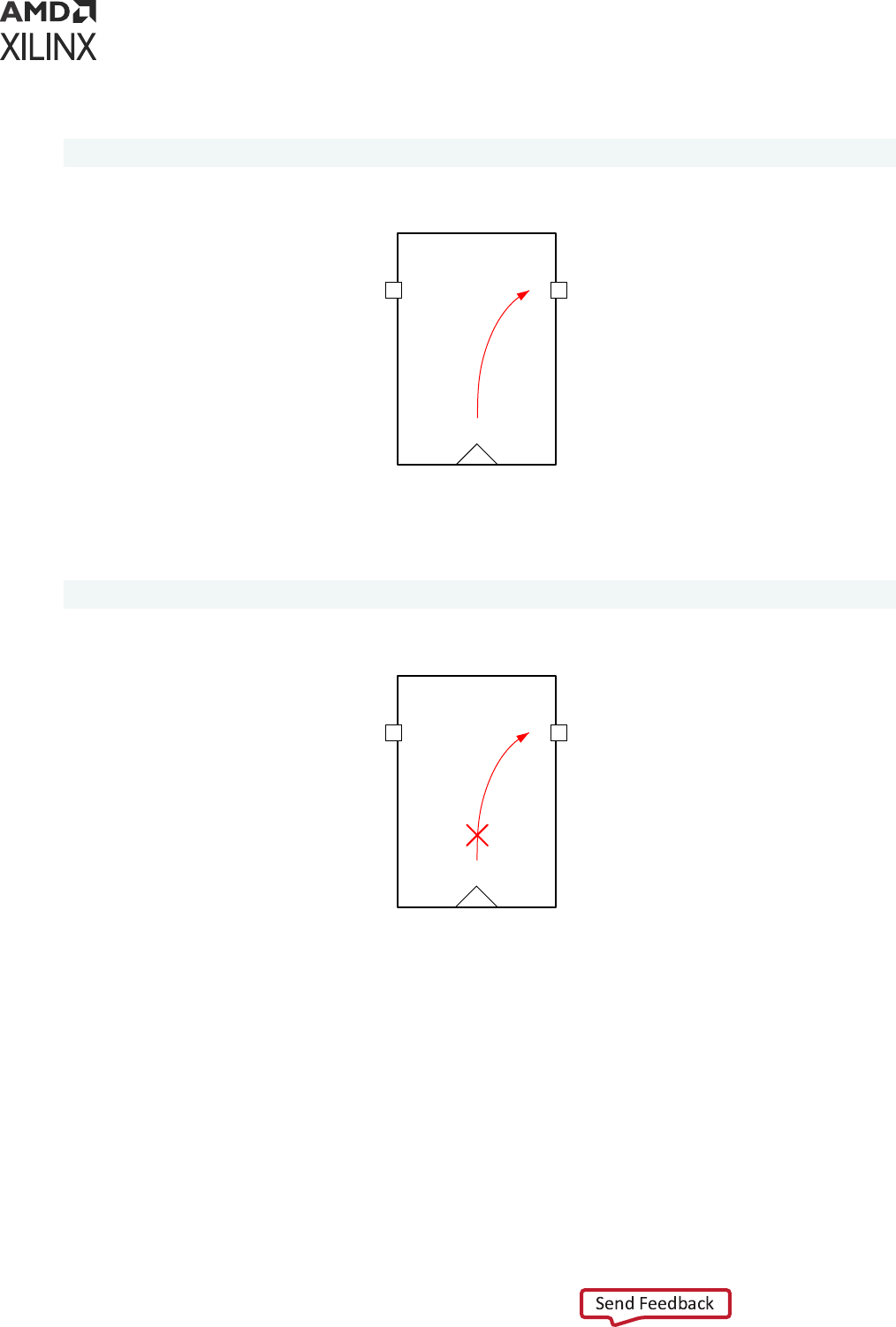

Two categories of clocks are idened by the wizard, as shown in the following gure:

Figure 11: Recommended Primary Clocks

• The primary clocks needed for compung the ming slack for setup, hold, recovery, and

removal checks appear in the Recommended Constraints table.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 28

• The clocks only needed for performing pulse width checks (min_period, max_period,

max_skew, min_low_pulse_width, and min_high_pulse_width) appear in the Constraints For

Pulse Width Check Only table. By default, these clocks are unchecked because they are only

used for reporng purposes and do not inuence the implementaon tools quality of result.

The wizard automacally idenes the proper clock source point for the constraint. In most

cases, the clock source point is an input clock port, and in some special cases it is the output of a

primive that does not have a ming arc. For example, in 7 series devices, the wizard idenes

missing primary clocks on the output of GT_CHANNEL primives. For UltraScale™ devices, the

Vivado Design Suite is able to auto-derive the GT_CHANNEL output clocks based on the

incoming clock characteriscs and the GT_CHANNEL conguraon and connecvity.

Consequently, the wizard recommends primary clocks located upstream from the GT_CHANNEL

cells on the design boundary.

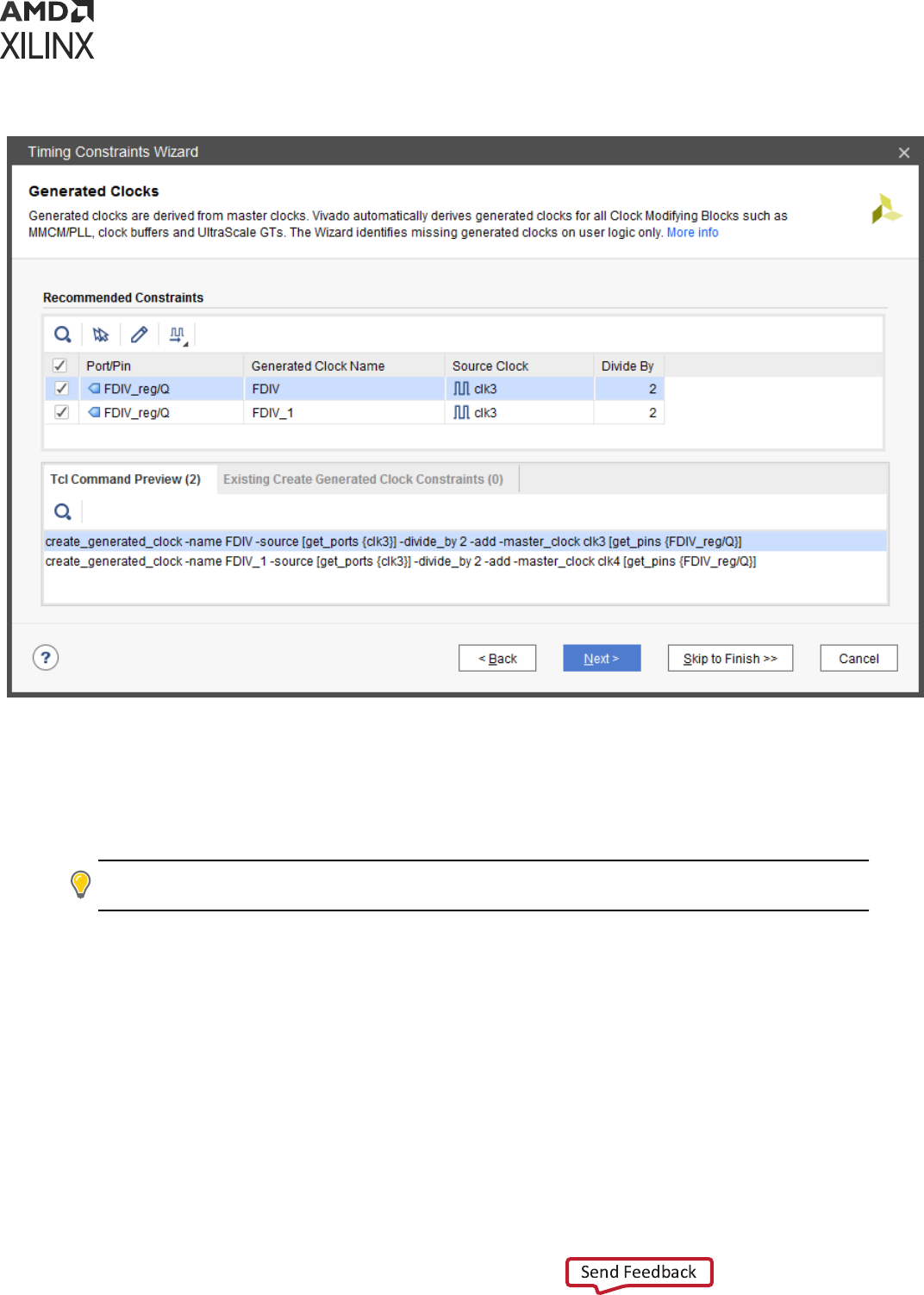

Generated Clocks

The Timing Constraints wizard recommends the creaon of a generated clock on the output of a

sequenal cell when it drives the clock pins of other sequenal cells either directly or through

some interconnect logic. Unlike PLL or MMCM, user logic cannot mulply the frequency of the

master clock, so the wizard only oers the opon to specify a division coecient, as shown in

the following gure:

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 29

Figure 12: Generated Clocks Page of the Timing Constraints Wizard

When several master clocks reach the generated clock source point, the wizard creates all the

corresponding generated clocks, using unique names and clear reference to individual master

clocks. The previous gure illustrates the scenario where two clocks (clk3 and clk4) reach the

sequenal cell FDIV_reg. Consequently, two generated clock constraints (FDIV and FDIV_1) are

recommended.

TIP:

Some clocking topologies, such as cascaded registers on the clock path, might require that you run the

Timing Constraints wizard mulple mes to discover all the missing generated clocks.

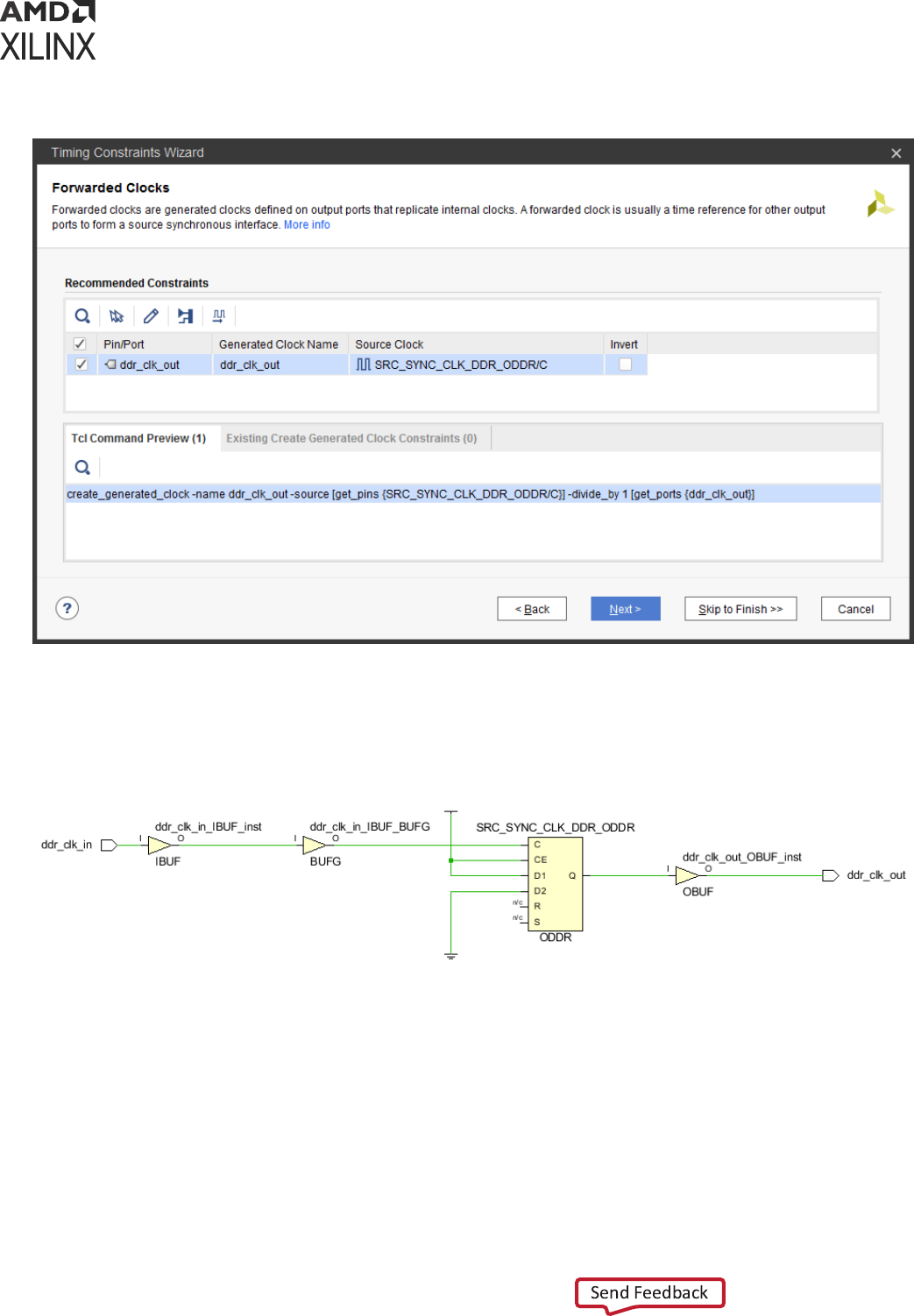

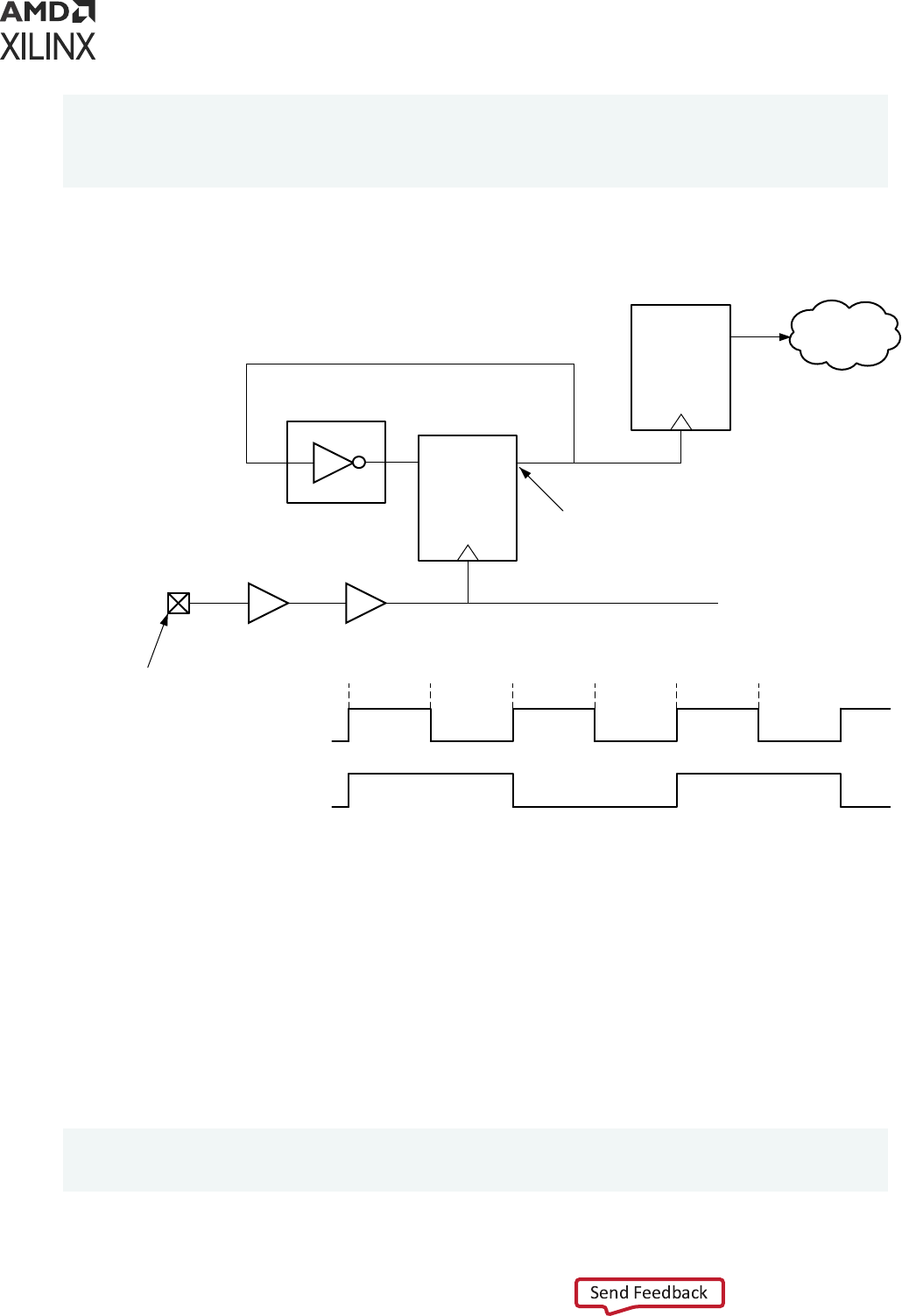

Forwarded Clocks

The Timing Constraints wizard recommends generated clock constraints on output ports that are

driven by double data-rate registers with constant inputs. Based on the input constant

connecvity, the generated clock phase is adjusted to either posive (0 degree phase shi) or

inverted (180 degree phase shi). The master clock used in the constraint is the clock that

reaches the clock pin of the double data-rate register. See the Source Clock column of the

Recommended Constraints table in the following gure:

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 30

Figure 13: Recommended Forwarded Clocks

For the 7 series device family, the topology recognized by the wizard is shown in the following

gure. There is no restricon on the nature of the master clock or the output buer.

Figure 14: 7 Series Forwarded Clock Typical Circuitry

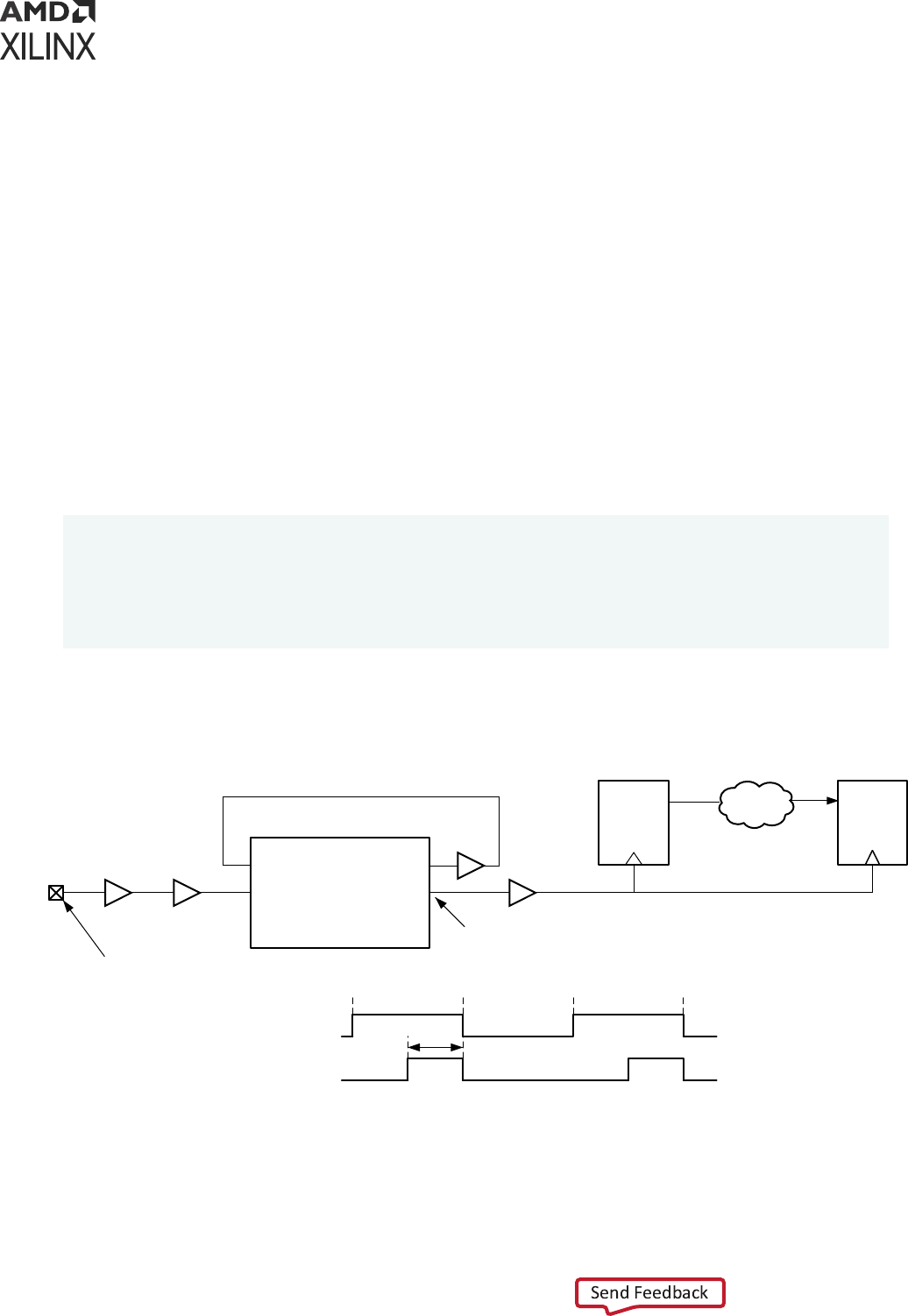

For the UltraScale device family, the ODDR and ODDRE1 primives are automacally retargeted

to OSERDESE3 with the property ODDR_MODE=TRUE. The wizard recognizes the topology

shown in the following gure, where OSERDESE3/D[0] is connected to 1 and OSERDESE3/D[4]

is connected to 0 (no phase-shi).

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 31

Figure 15: UltraScale Forwarded Clock Typical Circuitry

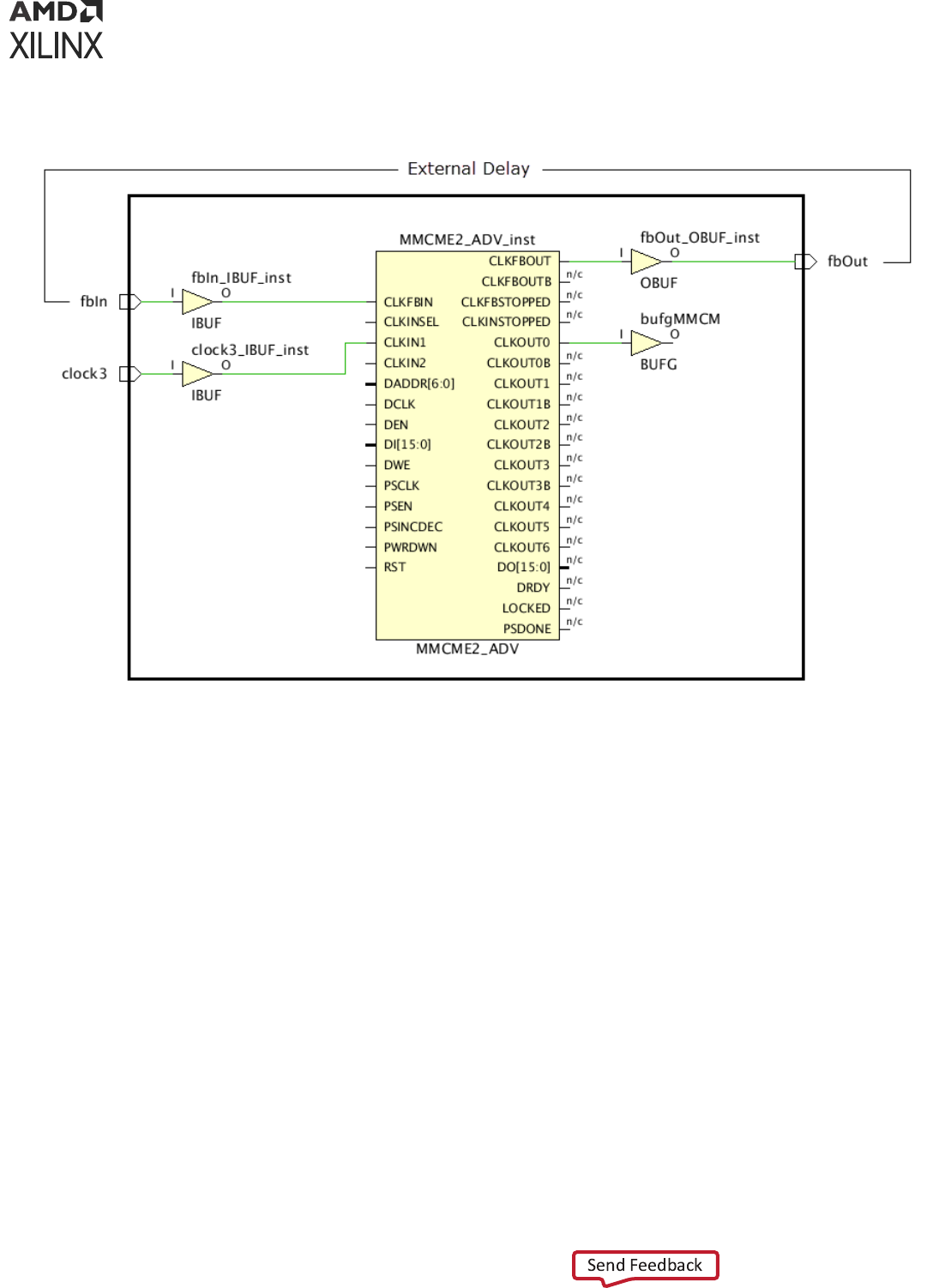

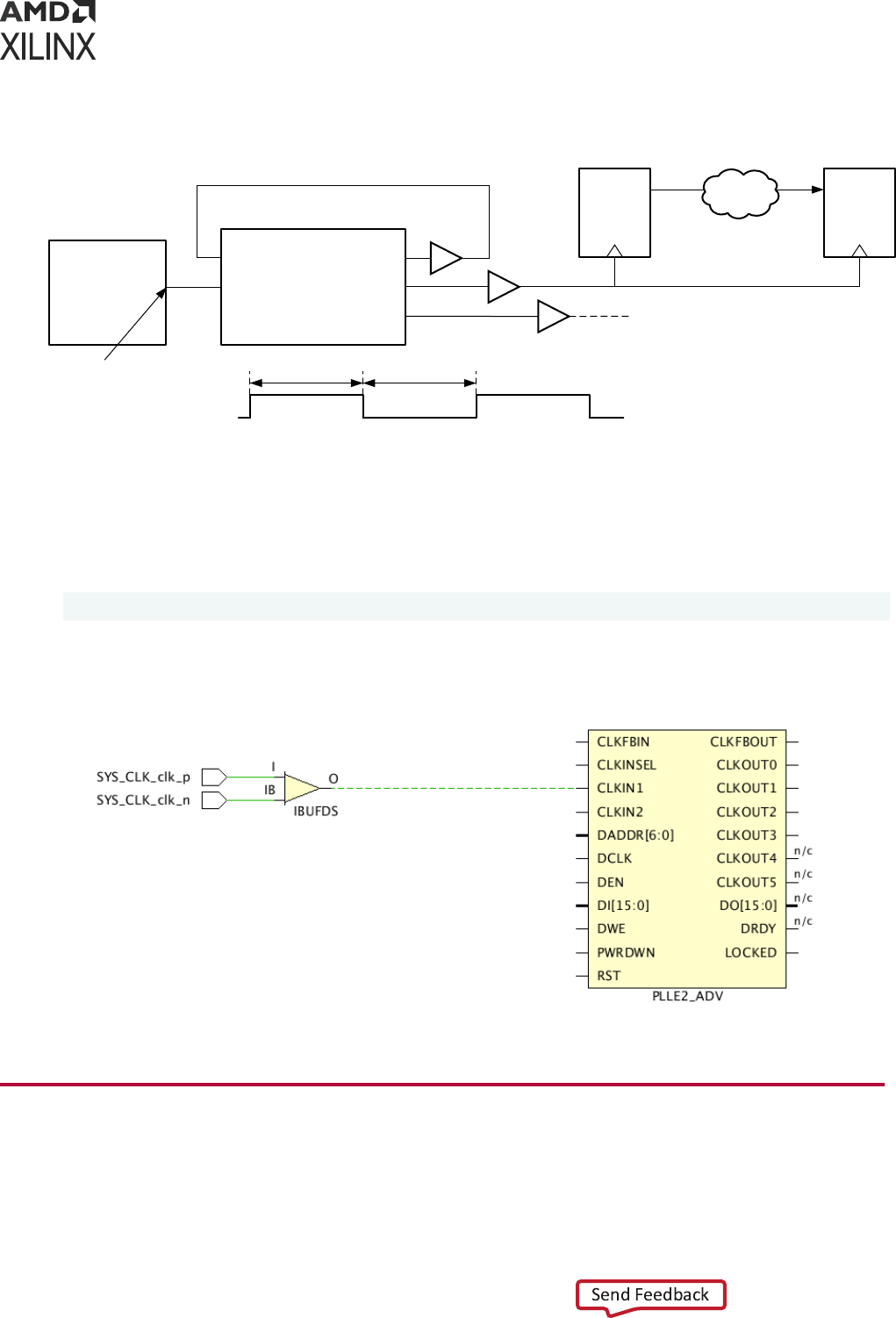

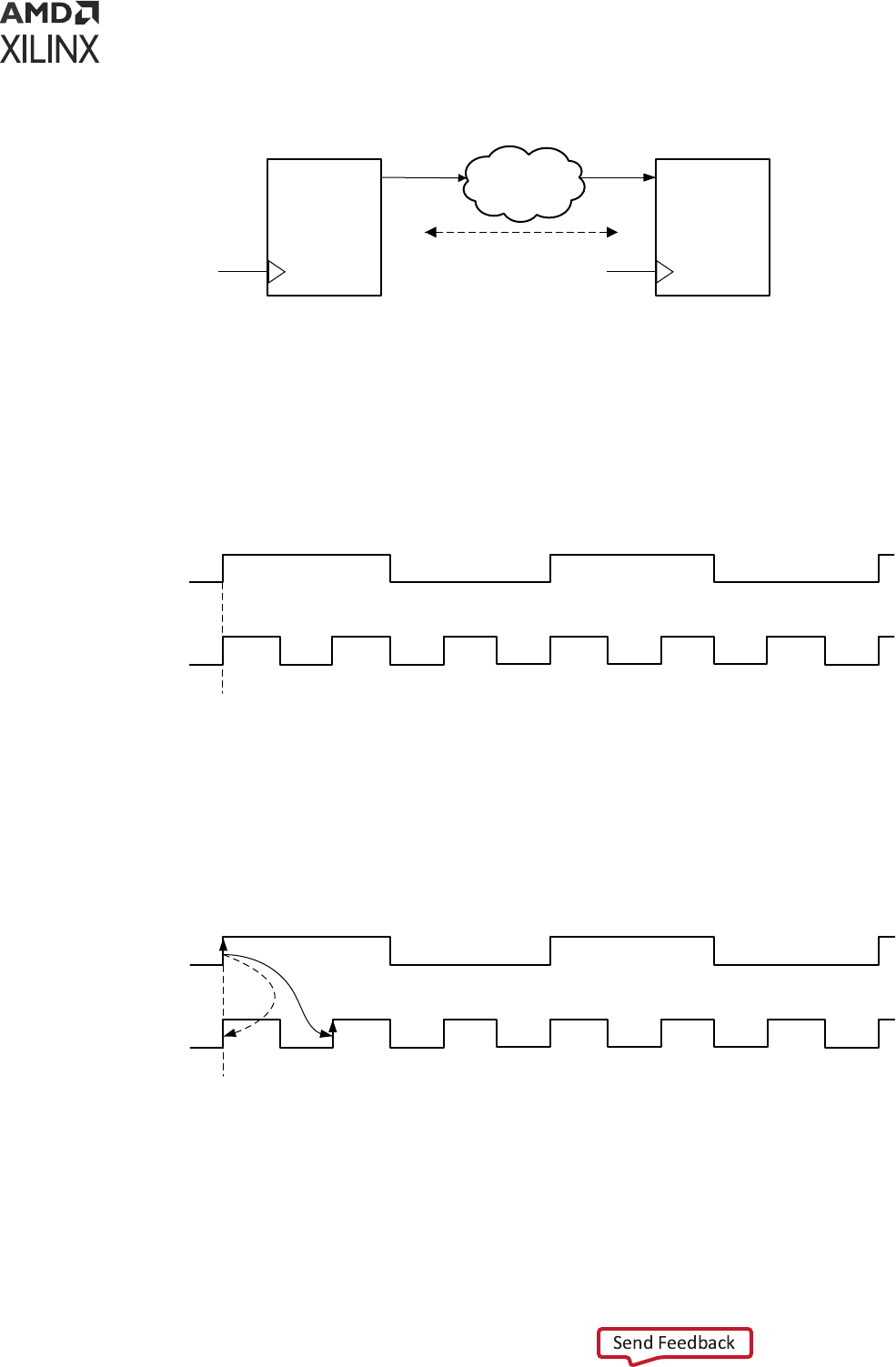

External Feedback Delays

The Timing Constraints wizard analyzes the feedback loop connecvity of the MMCM and PLL

cells present in the design. External delay constraints (min and max) are recommended when the

CLKFBIN and CLKFBOUT pins are connected to the design ports through IO buers and the

MMCM or PLL property COMPENSATION=EXTERNAL. The following gure illustrates the

recommended External Delay constraints.

Figure 16: Recommended External Delay Constraints

The following gure illustrates a typical MMCM with external feedback path circuit.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 32

Figure 17: Typical MMCM External Feedback Path Circuit

In the current Vivado Design Suite release, the Timing Constraints wizard cannot recommend

external delay constraints when there is a sequenal cell in the feedback path, such as ODDR,

which is used for generang a forwarded clock. In this case, you must create the external delay

constraints manually or using the Timing Constraints window aer exing the wizard.

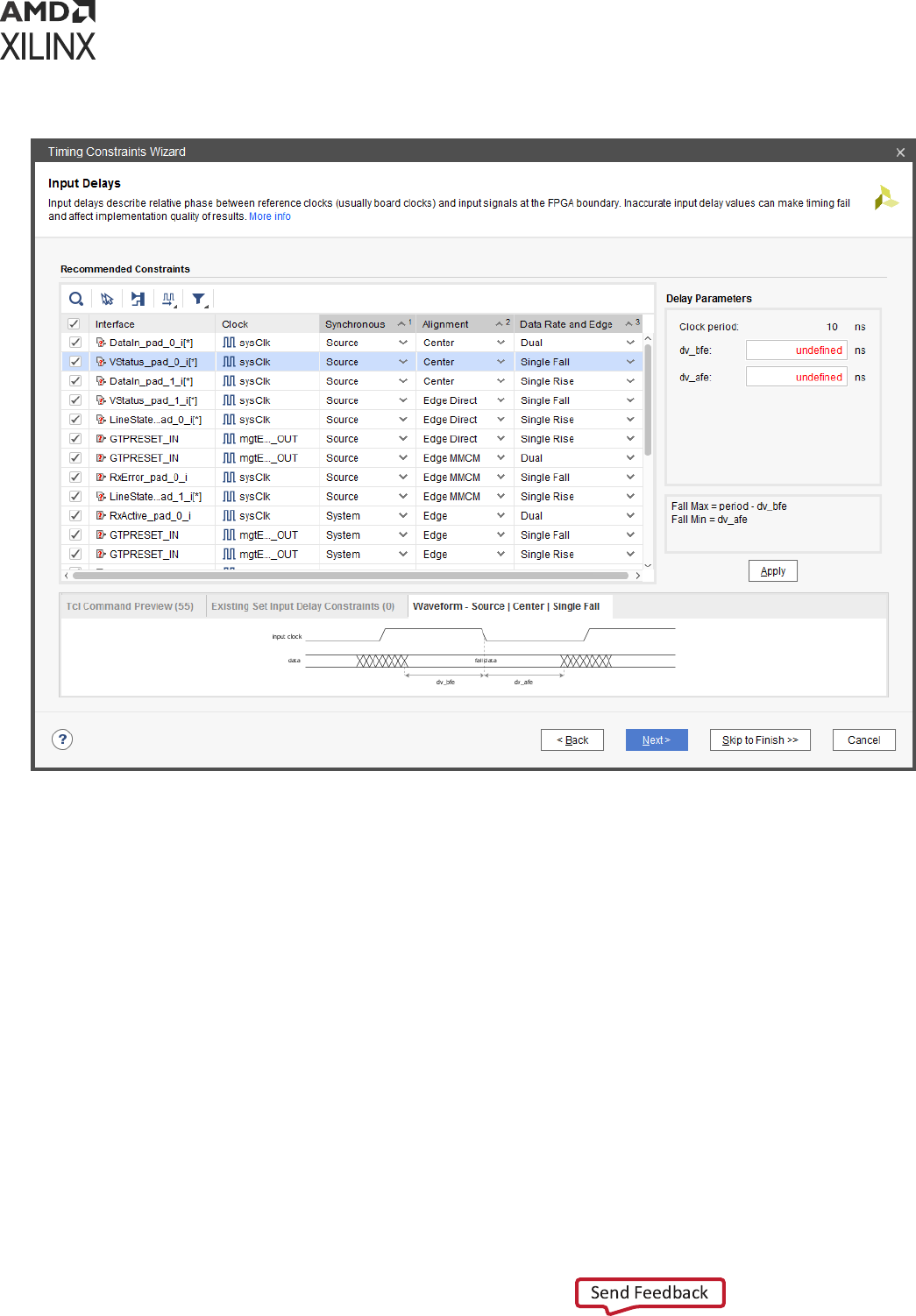

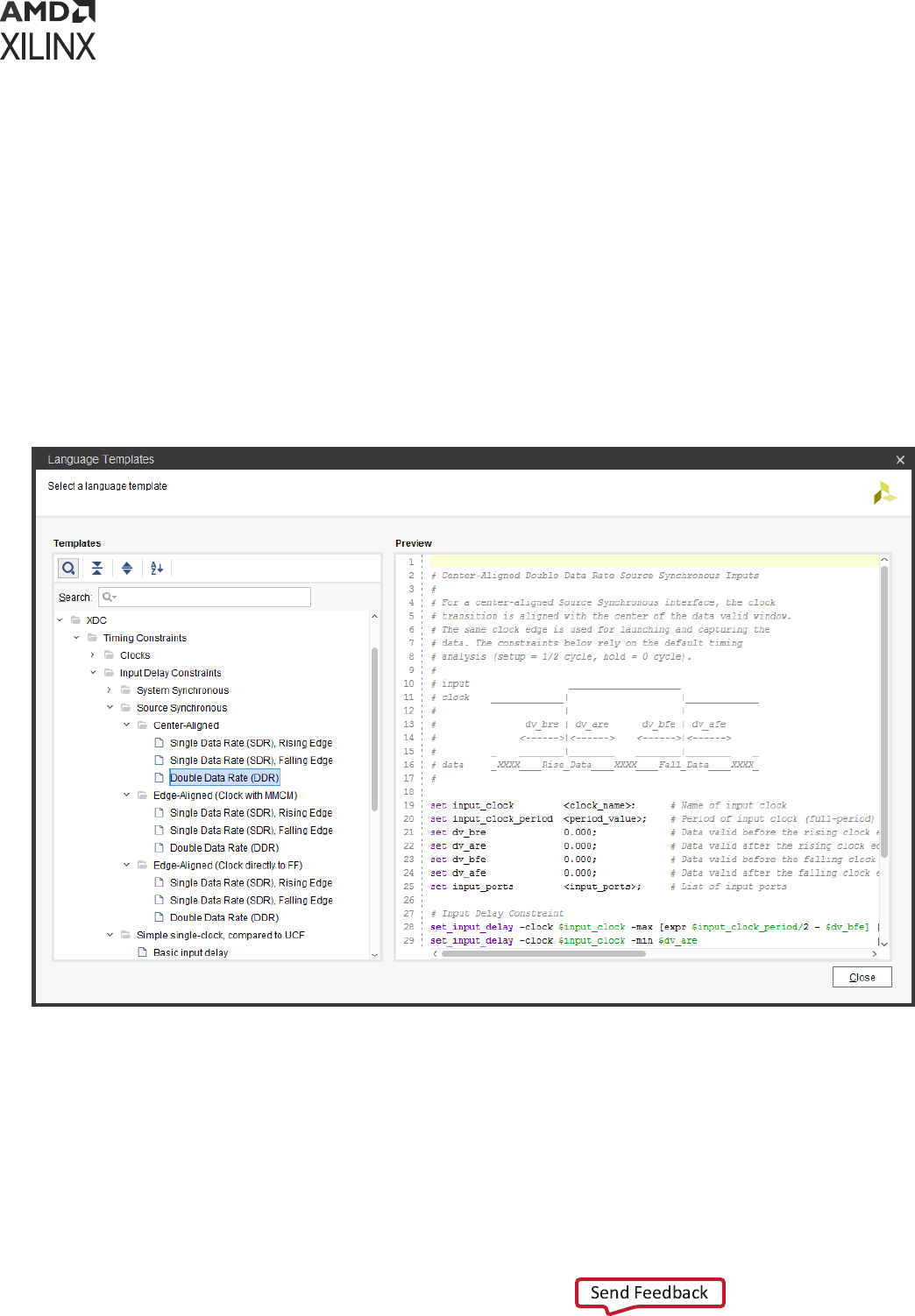

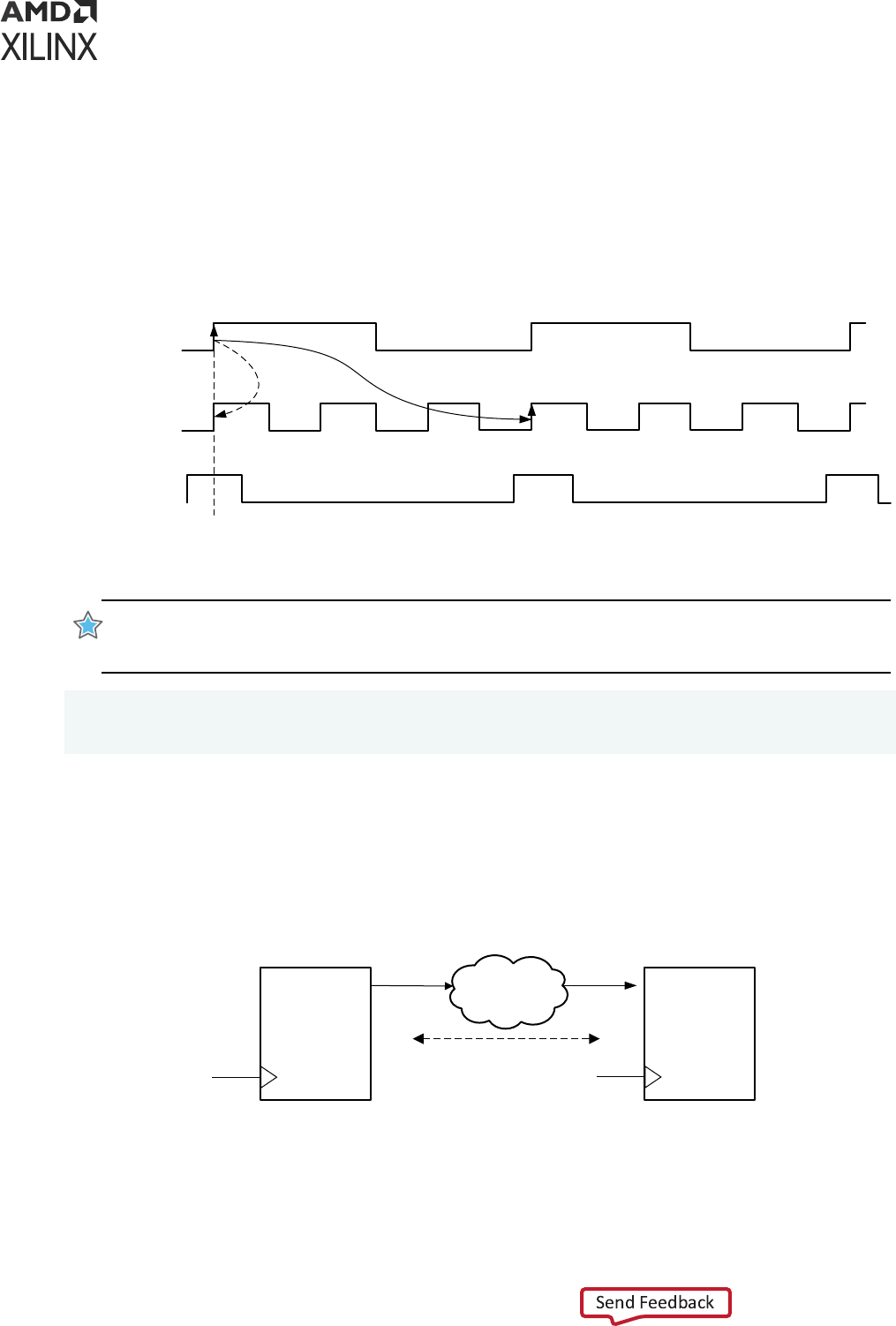

Input Delays

The Timing Constraints wizard analyzes all paths from input ports to idenfy their desnaon

clock inside the design and their acve edges. Based on this informaon, the wizard recommends

basic system synchronous input delay constraints that are based on the XDC templates available

in the Vivado IDE (see XDC Templates for templates). The waveform associated with the selected

template is displayed at the boom of the window in the Waveform tab when you select a

constraint entry in the Recommended Constraints table.

The following gure shows an example of several input constraints proposed by the wizard and

parally edited by the user.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 33

Figure 18: Recommended Input Delay Constraint Templates

For each constraint, you can edit three characteriscs in order to specify the appropriate

waveform that corresponds to the actual interface ming on the board:

• Synchronous: Describes the nature of the clock-data relaonship.

• System (for System Synchronous interface): Use this seng when the data is launched and

captured by dierent clock edges that are 1 period or ½ period apart.

• Source (for Source Synchronous interface): Use this seng when the data is launched and

captured by the same clock edge.

• Alignment: Describes the data transion alignment with respect to the acve clock edge.

• For System Synchronous interfaces only:

• Edge: Use this seng when the clock and data transion at the same me.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 34

• For Source Synchronous interfaces only:

• Center: Use this seng when the clock transions in the middle of the data valid

window.

• Edge Direct: Use this seng when the clock transions at the beginning of the data

valid window.

• Edge MMCM: Use this seng when the clock transions at the end of the data valid

window.

• Data Rate and Edge : Describes the acve clock edges constrained by the template. The

default value recommended by the wizard is based on the acve clock edges of the capturing

sequenal cell.

• Single Rise: Use this seng for cases where only the rising clock edges launch the data

outside the FPGA.

• Single Fall: Use this seng for cases where only the falling clock edges launch the data

outside the FPGA.

• Dual: Use this seng for cases where both rising and falling clock edges launch the data

outside the FPGA.

The recommended clock is usually the board clock related to the input path sequenal cell.

When the input path internal clock is an MMCM or PLL generated clock, the board clock that

drives the MMCM or PLL is used as the input constraint reference clock. The only excepons

exist when the internal clock waveform and the board clock waveform are not idencal, such as

the following scenarios:

• Dierent period scenario: The input constraint references a virtual clock that has the same

waveform as the internal clock so that the setup analysis is performed with a 1 cycle path

requirement. The virtual clock is automacally created.

• Posive phase-shi clock scenario: The wizard uses a virtual clock as the reference clock. The

virtual clock is automacally created with the same waveform as the board clock. In addion,

the wizard also species a mulcycle path constraint between the virtual clock and the

internal clock to adjust the default analysis to 1 period + the amount of phase-shi for setup.

The combinaon of the virtual clock and the mulcycle path constraint provides simpler

constraints for the Vivado Design Suite mer to handle and can only aect input ports that

reference to the virtual clock.

Note that for a negave phase-shi, the virtual clock and the mulcycle path constraint are

not needed because the default setup path requirement is 1-cycle minus the amount of

phase-shi.

The wizard does not allow you to change the reference clock selected for the constraint. To do

so, you must manually edit the XDC les or use the Timing Constraints window aer exing the

wizard.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 35

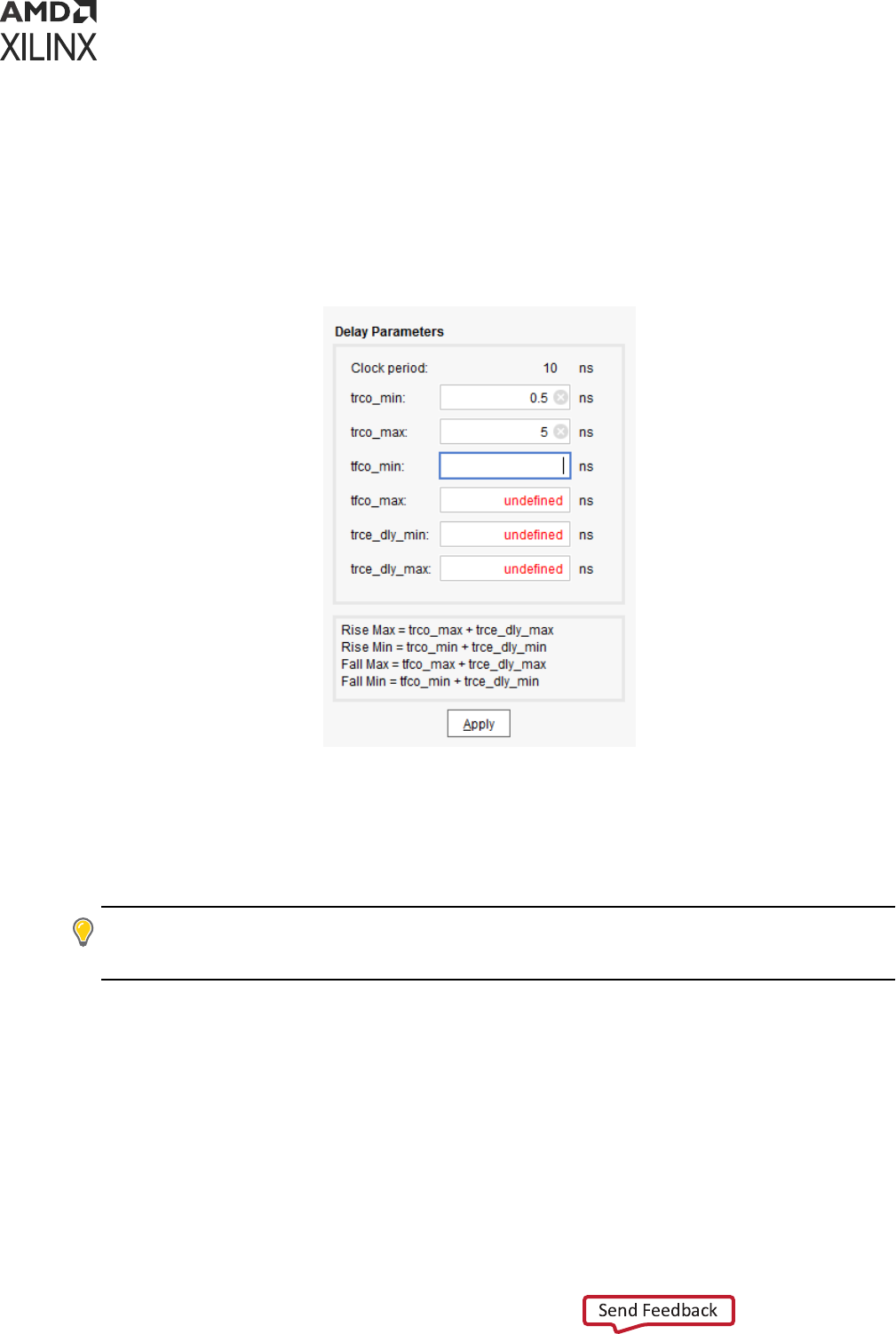

Aer you select the proper template, enter the delay parameter values in the Delay Parameters

panel located on the right hand side of the wizard and then click Apply to validate the entries.

The input delay equaons are displayed below the delay parameter elds and on some of the

template waveforms. The following gure shows the Delay Parameters panel for the DDR

System Synchronous interface template.

Figure 19: Input Delay Parameters Panel

To accelerate the delay parameter entry task, you can select and edit several constraints with

same clock and same template at once.

Aer the constraints have been completed and applied, you can review their corresponding Tcl

syntax in the Tcl Command Preview tab or you can click Next to proceed to the next step.

TIP:

The Timing Constraints wizard skips input ports with a false path constraint. This is parcularly useful

for skipping asynchronous resets that usually do not have a known phase relaonship with any clock of the

design. The false path constraint can only be created outside the wizard.

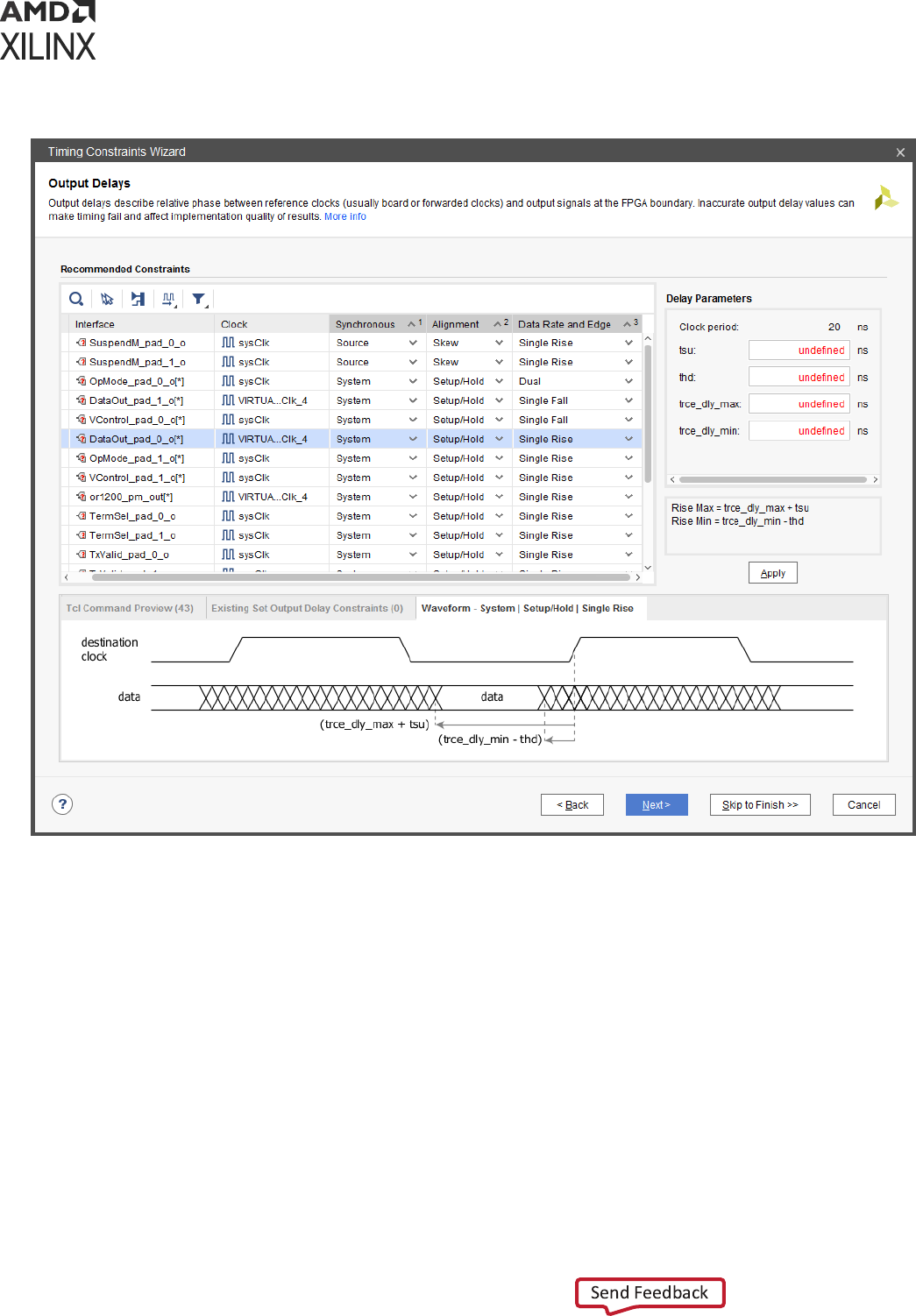

Output Delays

Similar to the Input delays step, the Timing Constraints wizard analyzes the paths to all output

ports to idenfy their source clocks inside the design and their acve edges. The template

selecon rules are the same as described in Input Delays. The following gure shows several

output constraints proposed by the wizard and parally edited by the user.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 36

Figure 20: Recommended Output Delay Constraint Templates

For each constraint, three characteriscs can be edited in order specify the appropriate

waveform that corresponds to the actual interface ming on the board:

• Synchronous: Describes the nature of the clock-data relaonship (see Input Delays for more

details).

• Alignment: Describes the data transion alignment with respect to the acve clock edge.

• Setup/Hold: Use this seng when the template delay parameters are specied based on

the data valid window ming characteriscs outside the FPGA.

• Skew (Source Synchronous only): Use this seng when the template delay parameters are

specied based on the skew requirements on the output pin of the FPGA.

• Data Rate and Edge: Describes the acve clock edges constrained by the template (see Input

Delays for more details).

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 37

As with recommended input delay constraints, the reference clock is typically the board clock,

except in the following cases:

• The board clock and the output path internal clock have dierent clock periods.

The output constraint references a virtual clock that has the same waveform as the internal

clock so that the setup analysis is performed with a 1-cycle path requirement. The virtual

clock is automacally created.

• The output path internal clock has a negave phase-shi compared to the board clock.

The wizard uses a virtual clock as the reference clock. The virtual clock is automacally

created with the same waveform as the board clock. In addion, the wizard also species a

mulcycle path constraint between the virtual clock and the internal clock to adjust the

default analysis to 1 period + the amount of phase-shi for setup. The combinaon of the

virtual clock and the mulcycle path constraint provides simpler constraints for the Vivado

Design Suite mer to handle and can only aect output ports that reference to the virtual

clock.

Note: For a posive phase-shi, the virtual clock and the mulcycle path constraint are not needed

because the default setup path requirement is 1 cycle minus the amount of phase-shi.

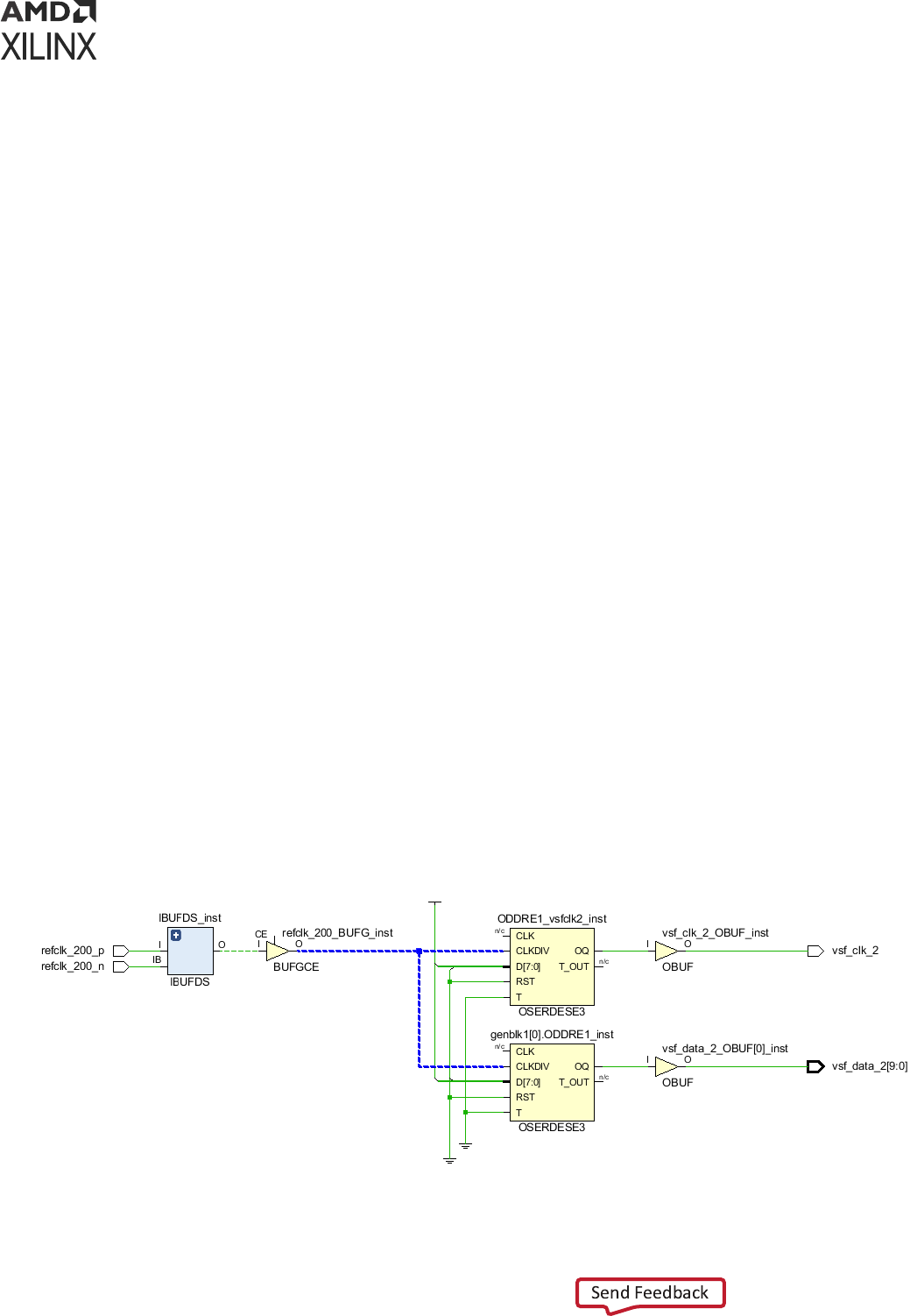

• A forwarded clock has been idened for ming the output path based on the shared clocking

connecvity.

The forwarded clock must have been created during the third step of the wizard "Forwarded

Clocks," or else the board clock or a virtual clock will be used as the output delay constraint

reference clock.

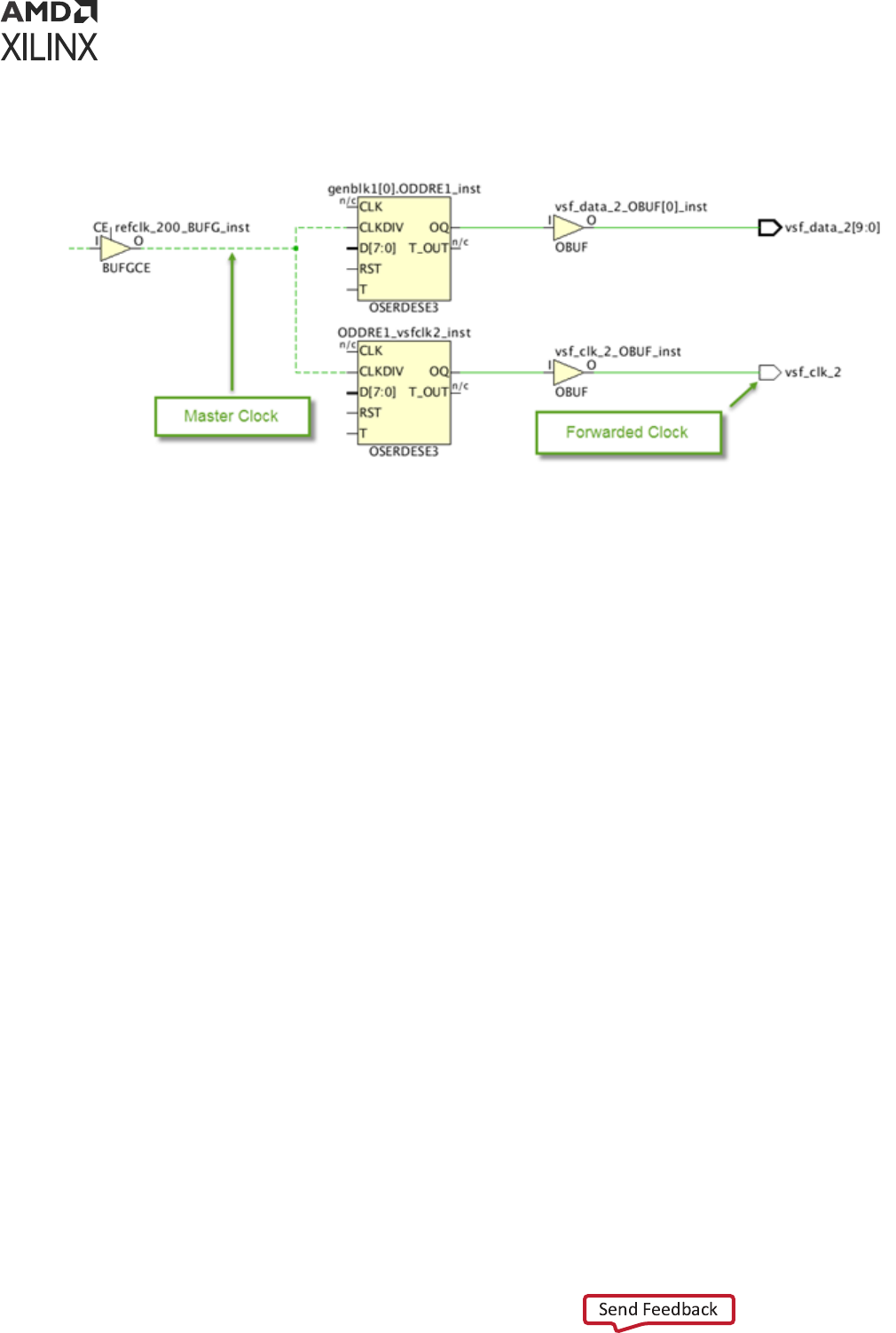

The following gure shows a basic example of an output source synchronous path along with its

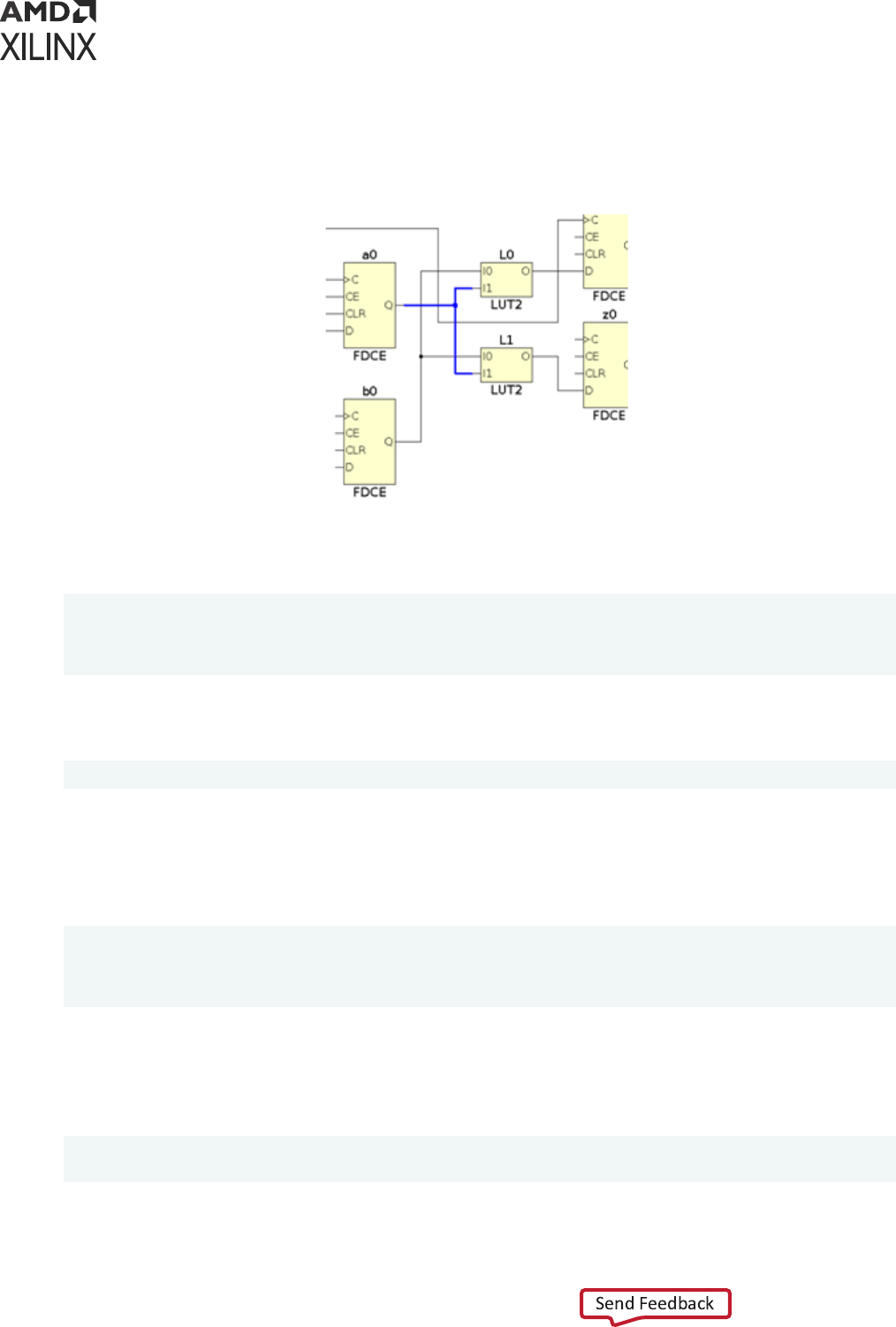

forwarded clock for the 7 series family. Both ODDR/OSERDES instances are connected to the

same clock net (highlighted in blue). The ck_vsf_clk_2 generated clock is already dened on

the vsf_clk_2 output port.

Figure 21: Example of a Source Synchronous Output Path with its Forwarded Clock

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 38

The following gure shows the corresponding constraints in the wizard.

Figure 22: Recommended Source Synchronous Output Path Delay Constraint with a

Forwarded Clock

Aer you select the proper template, you must enter the delay parameters values. To accelerate

the delay parameter entry task, you can select and edit several constraints with same clock and

same template at once. Aer the constraints have been completed and applied, you can review

their corresponding Tcl syntax in the Tcl Command Preview tab or you can click Next to proceed

to the next step.

TIP:

The Timing Constraints wizard skips output ports with a false path constraint. The false path

constraint can only be created outside the wizard.

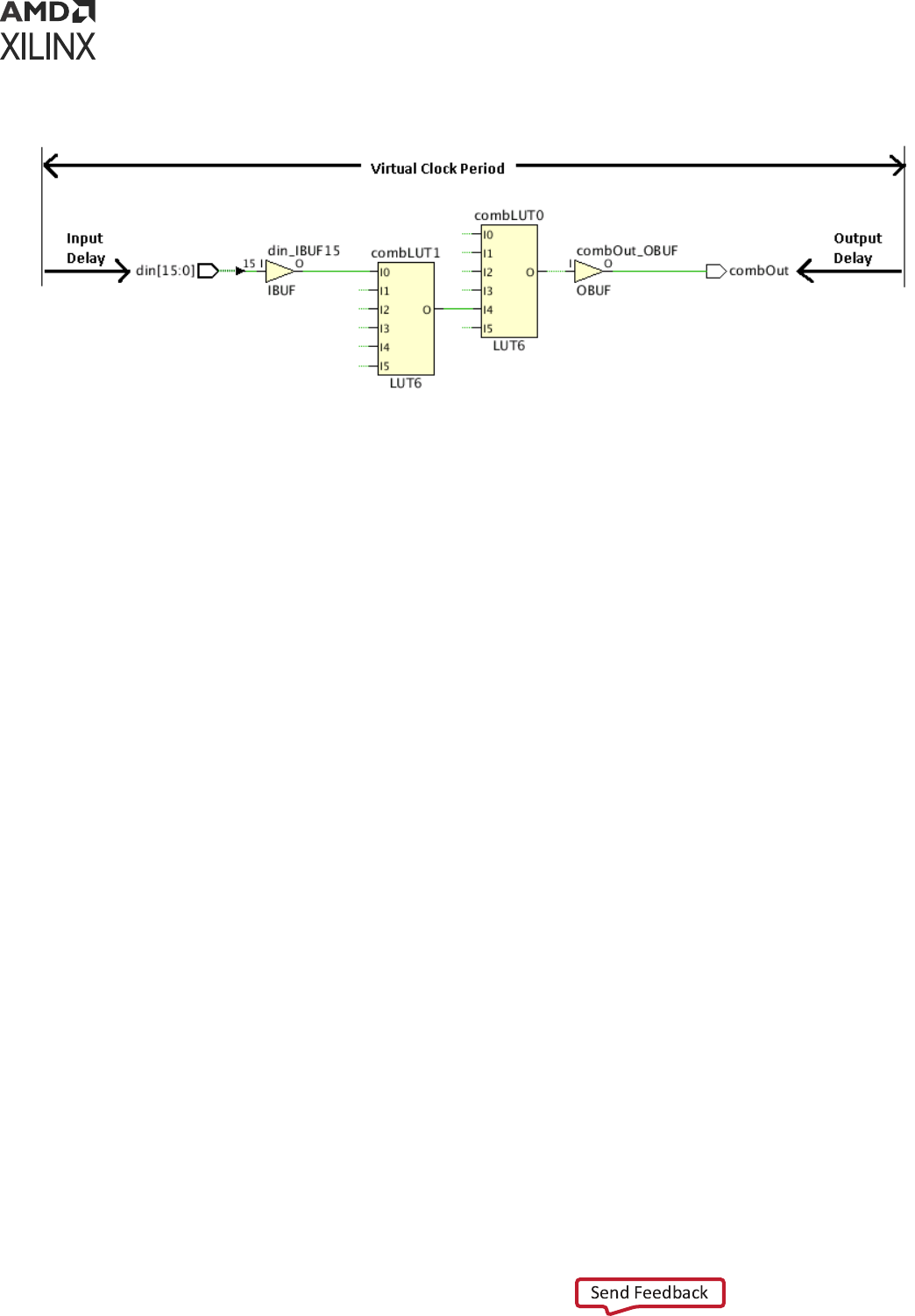

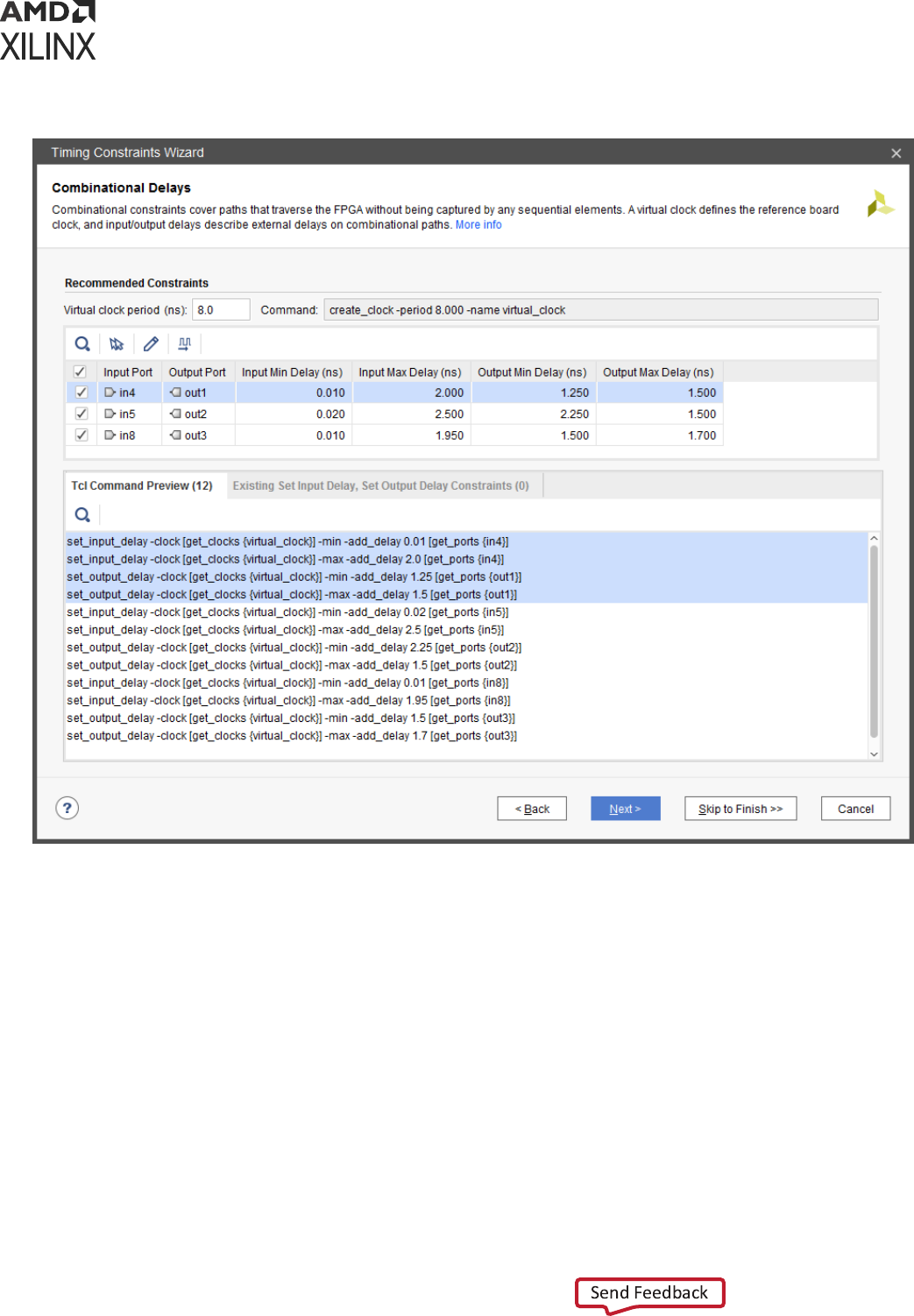

Combinatorial Delays

Some paths propagate directly from input ports to output ports without being captured inside

the device by a sequenal cell. If an input port is connected to both an output port and a

sequenal cell, the Timing Constraints wizard does not recommend combinaonal constraints

between the input/output port pair, because the input port should have been constrained during

the Input Delay step. For the combinaonal paths, the wizard recommends to dene a virtual

clock along with input and output delays on the design ports as shown in the following gure.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 39

Figure 23: Combinational Path Schematics and Delay Constraints

The nal combinaonal path delay constraints are:

• For setup analysis:

virtual clock period - max input delay - max output delay

• For hold analysis:

0 - min output delay - min input delay

The virtual clock period must be modied so that it is greater than the largest combinaonal

delay constraint across all constrained combinaonal paths. The following gure shows the delay

entries needed per input/output ports pair.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 40

Figure 24: Recommended Combination Paths Constraints

None of the input and output delay constraints override exisng ones. If a given port has

mulple delay constraints with respect to the same clock, the smallest value of all constraints is

used by the Vivado Timing analysis feature during hold analysis, and the largest one during setup

analysis.

Aer all delay entries have been lled, you can click Next to proceed to the next step.

Note: Alternavely, you can constrain combinaonal paths using the set_max_delay and

set_min_delay commands outside the Timing Constraints wizard.

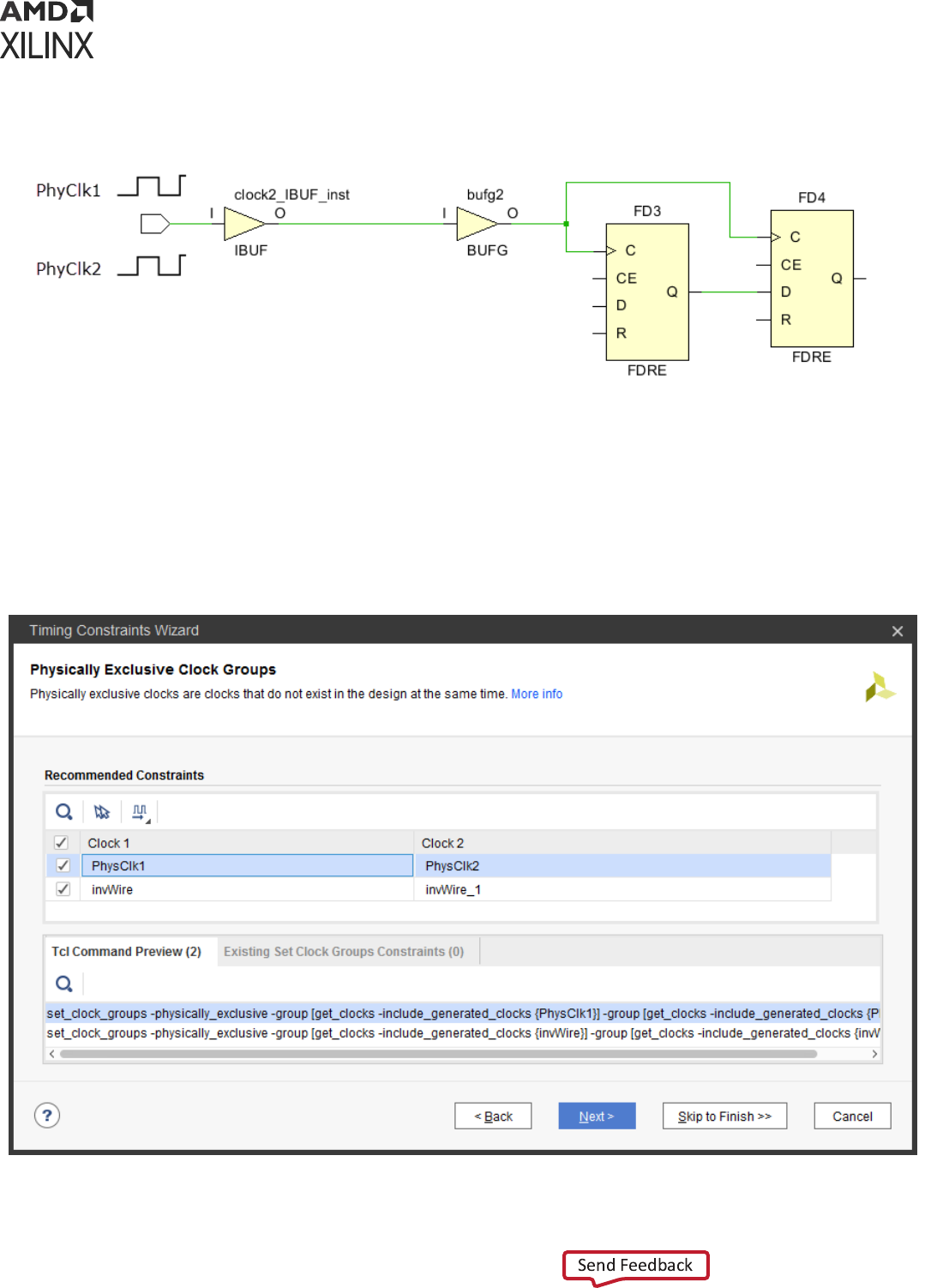

Physically Exclusive Clock Groups

Physically exclusive clocks are clocks that are dened on the same source point and propagate on

the same clock tree. The following gure shows an example where two primary clocks are

dened on the same input port.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 41

Figure 25: Example of a Design with Physically Exclusive Clocks

While their overlap is convenient for ming several applicaon modes with one design and

constraint database, these clocks and their children generated clocks should never be med

together. The Timing Constraints wizard idenes such clocks and recommends a clock groups

constraint to prevent unnecessary ming analysis on the clock domain crossing paths, as shown

in the following gure.

Figure 26: Example of a Design with Clock Groups Constraint

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 42

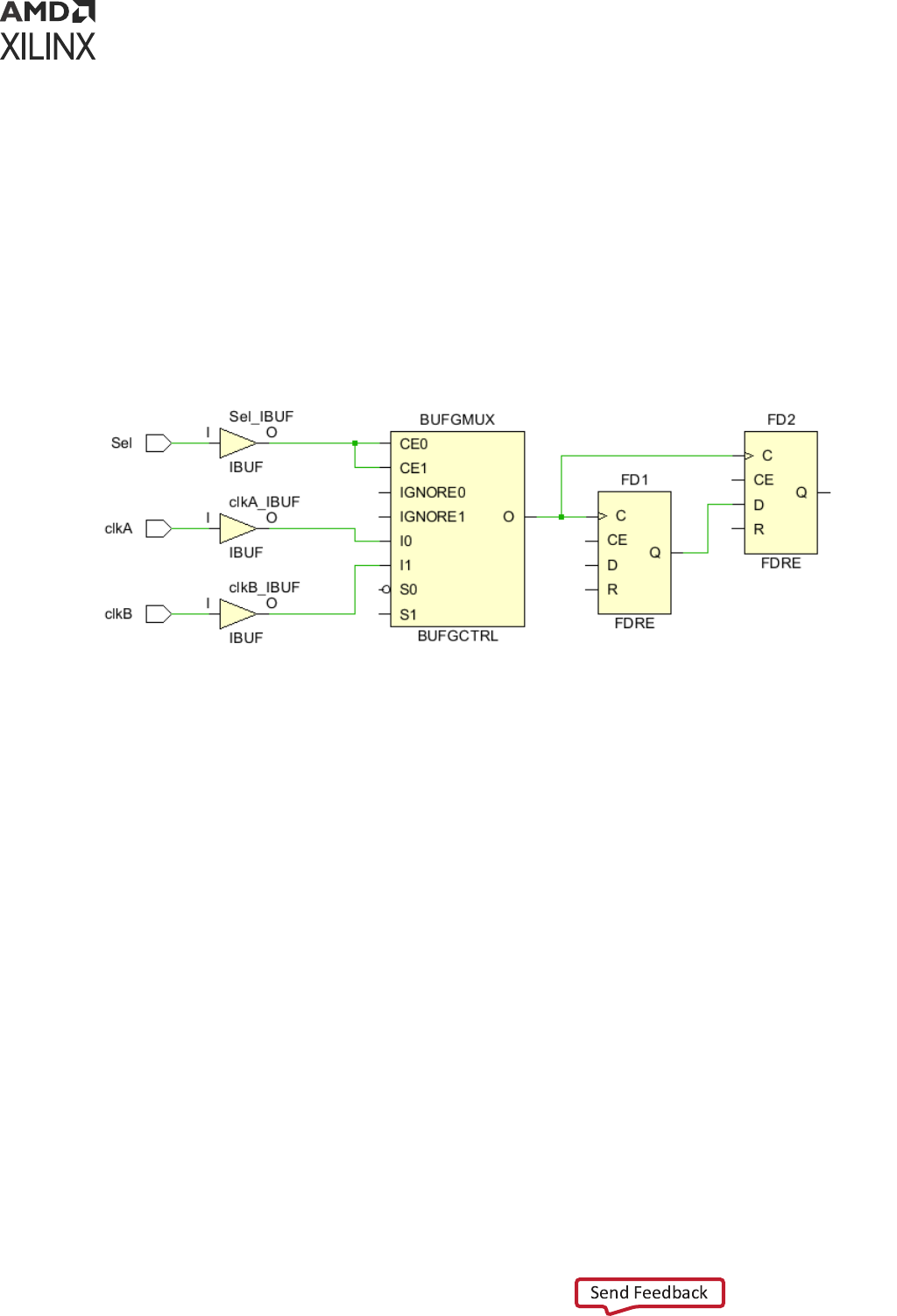

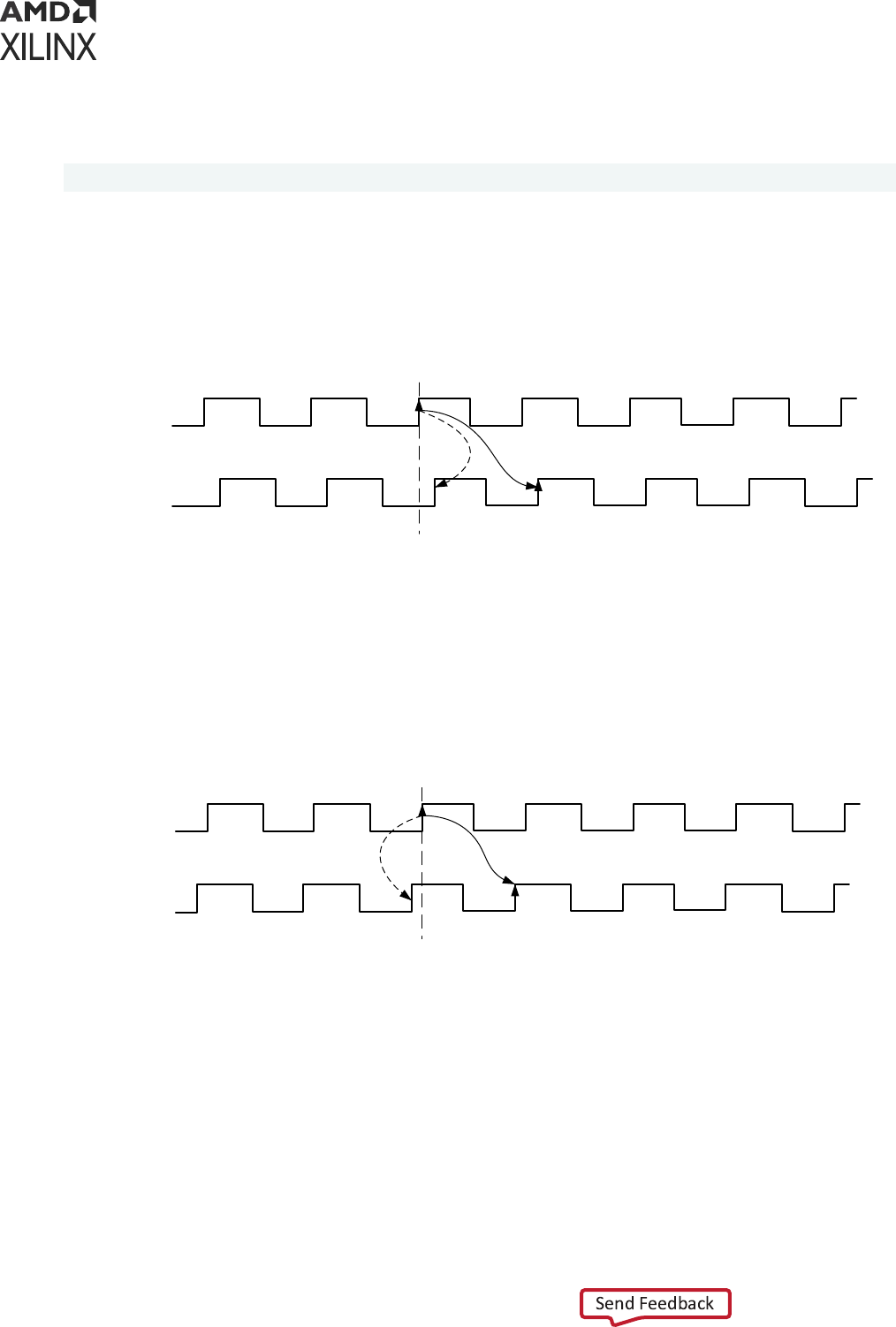

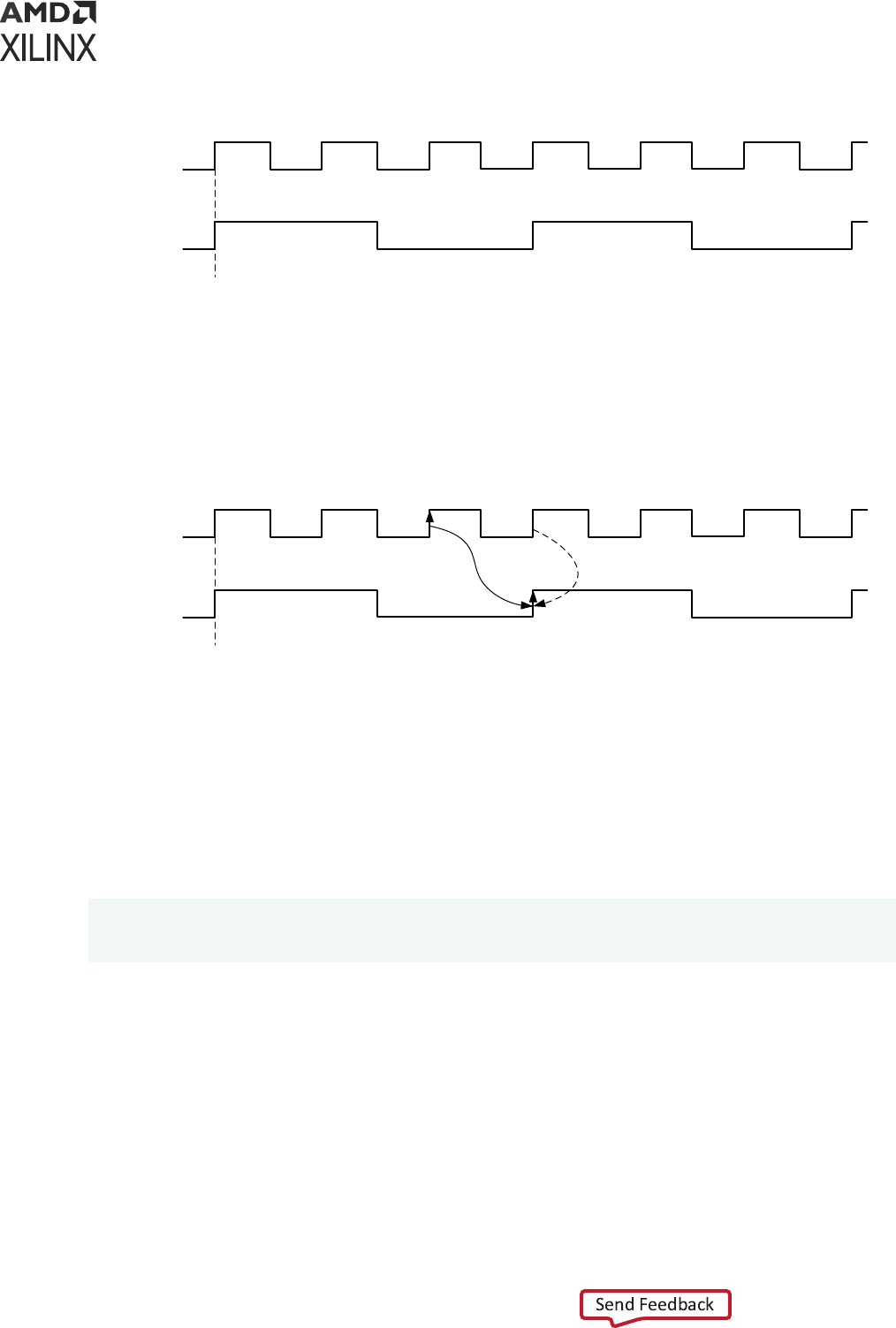

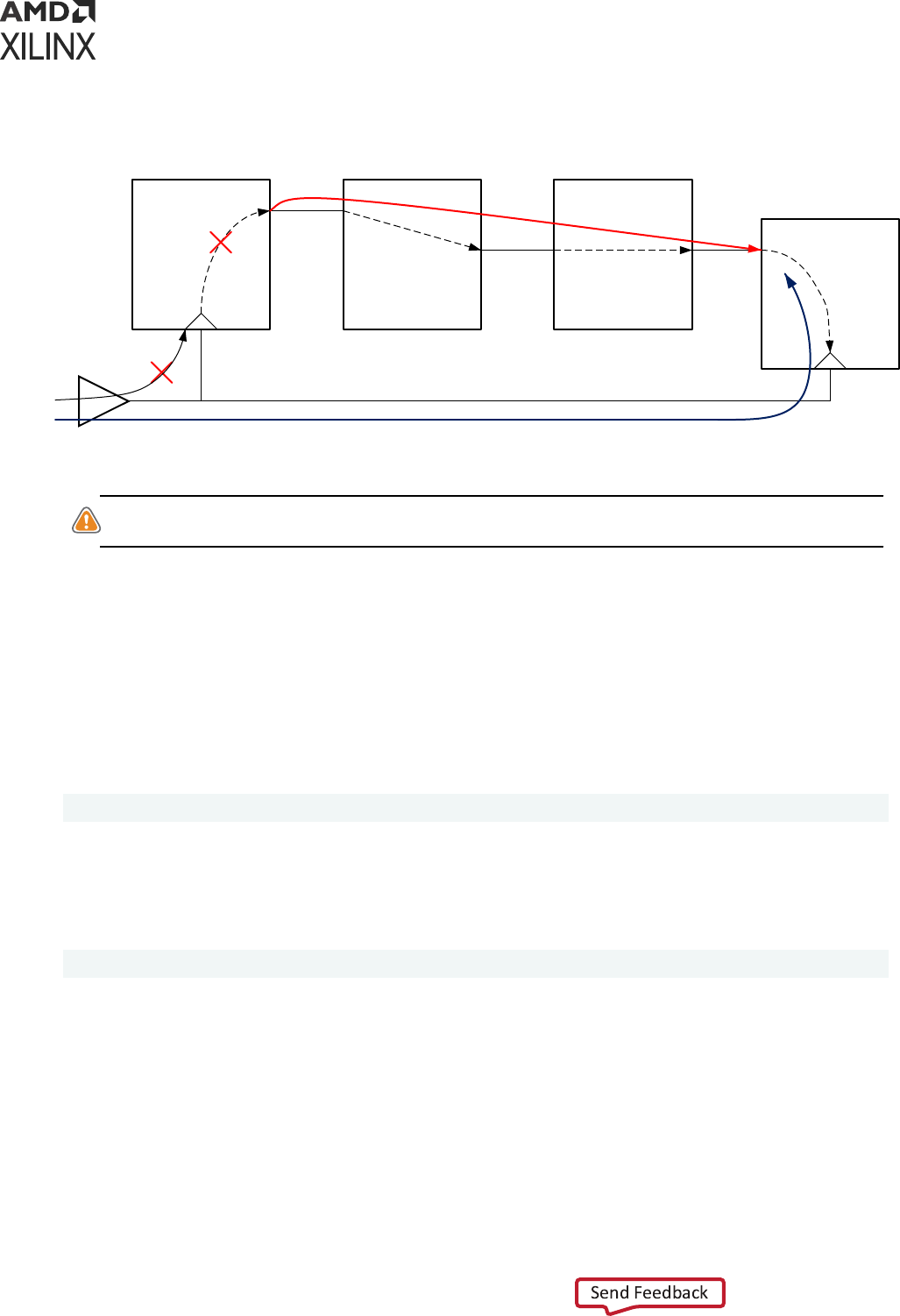

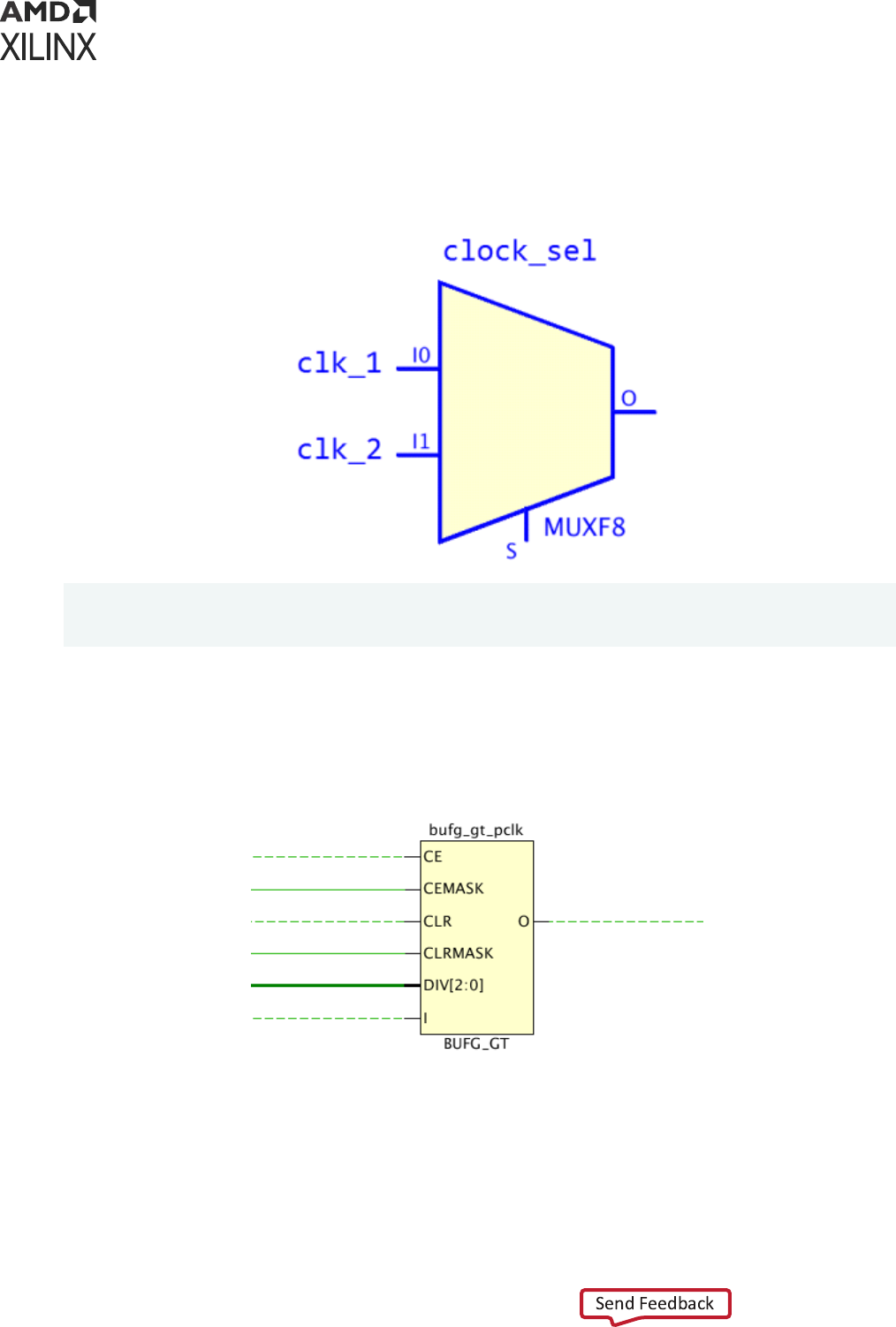

Logically Exclusive Clock Groups with No Interaction

Logically exclusive clocks are clocks that are dened on dierent source points but share part of

their clock tree due to a mulplexer or other combinaonal logic. The Timing Constraints wizard

idenes such clocks and recommends a clock groups constraint directly on them when they do

not have ming paths between each other except for the logic connected to their shared clock

tree. The following gure shows an example of two clocks, clkA and clkB, which are dened on

dierent input ports and start overlapping on the output of a BUFGMUX.

Figure 27: Example of Logically Exclusive Clocks with No Interaction

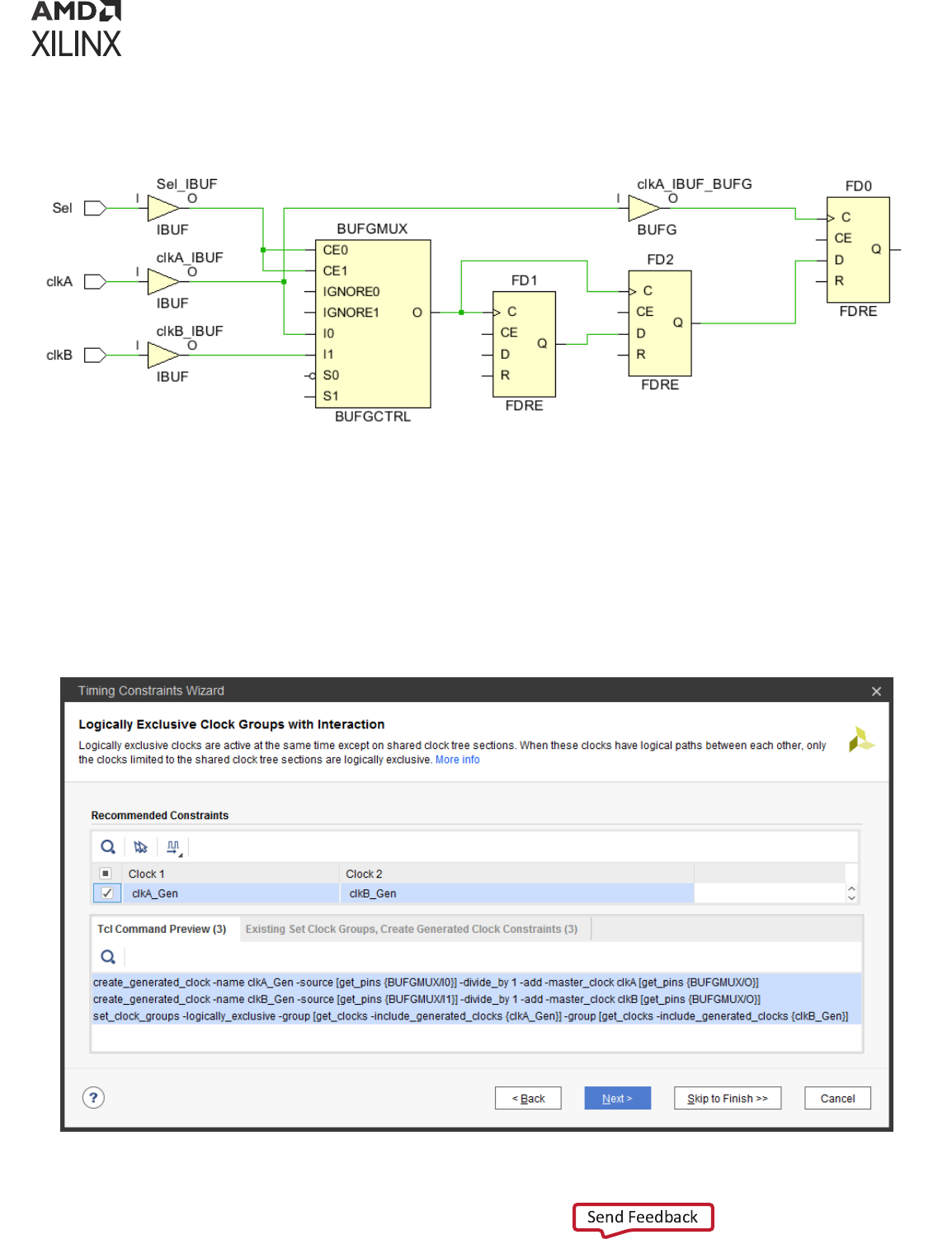

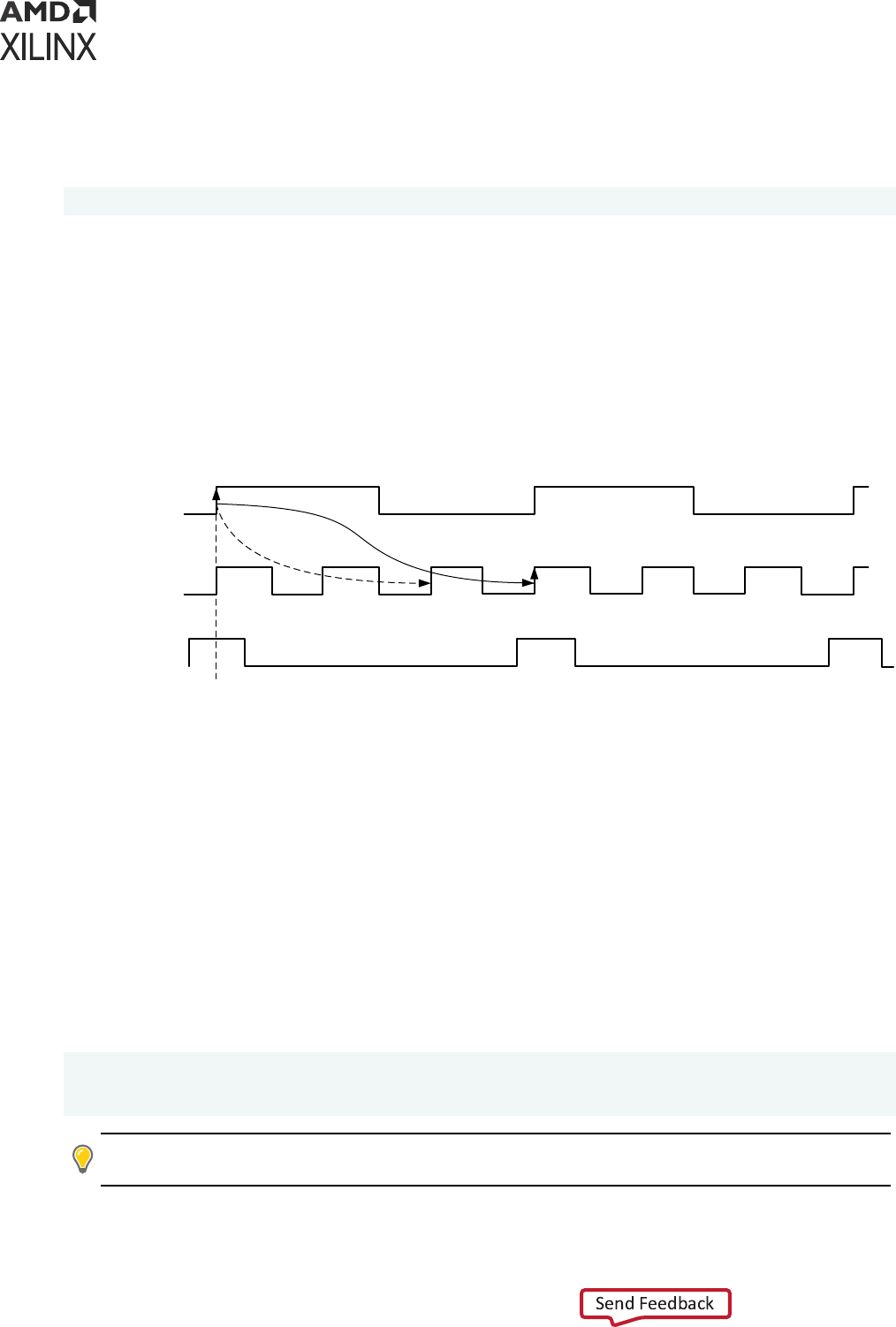

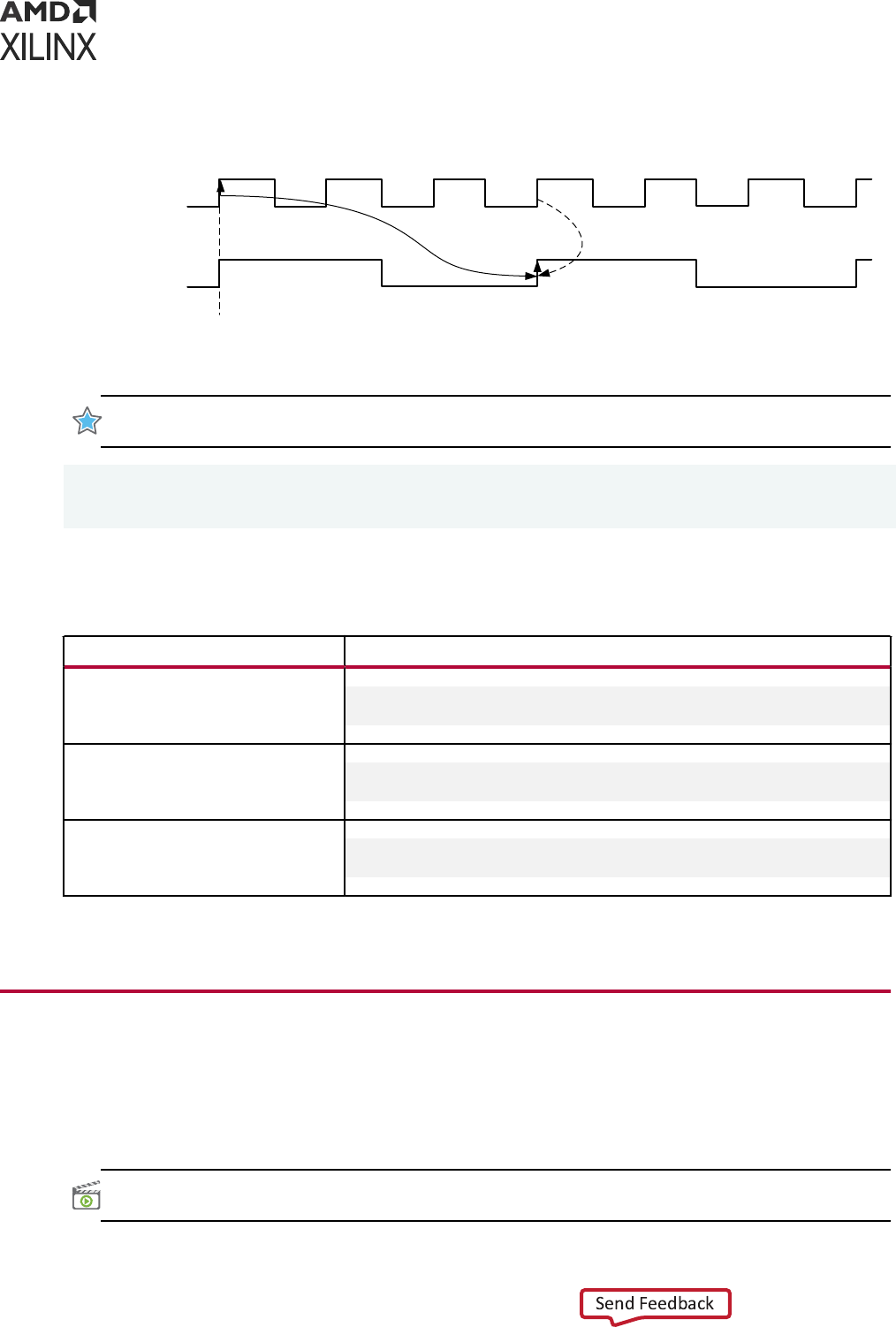

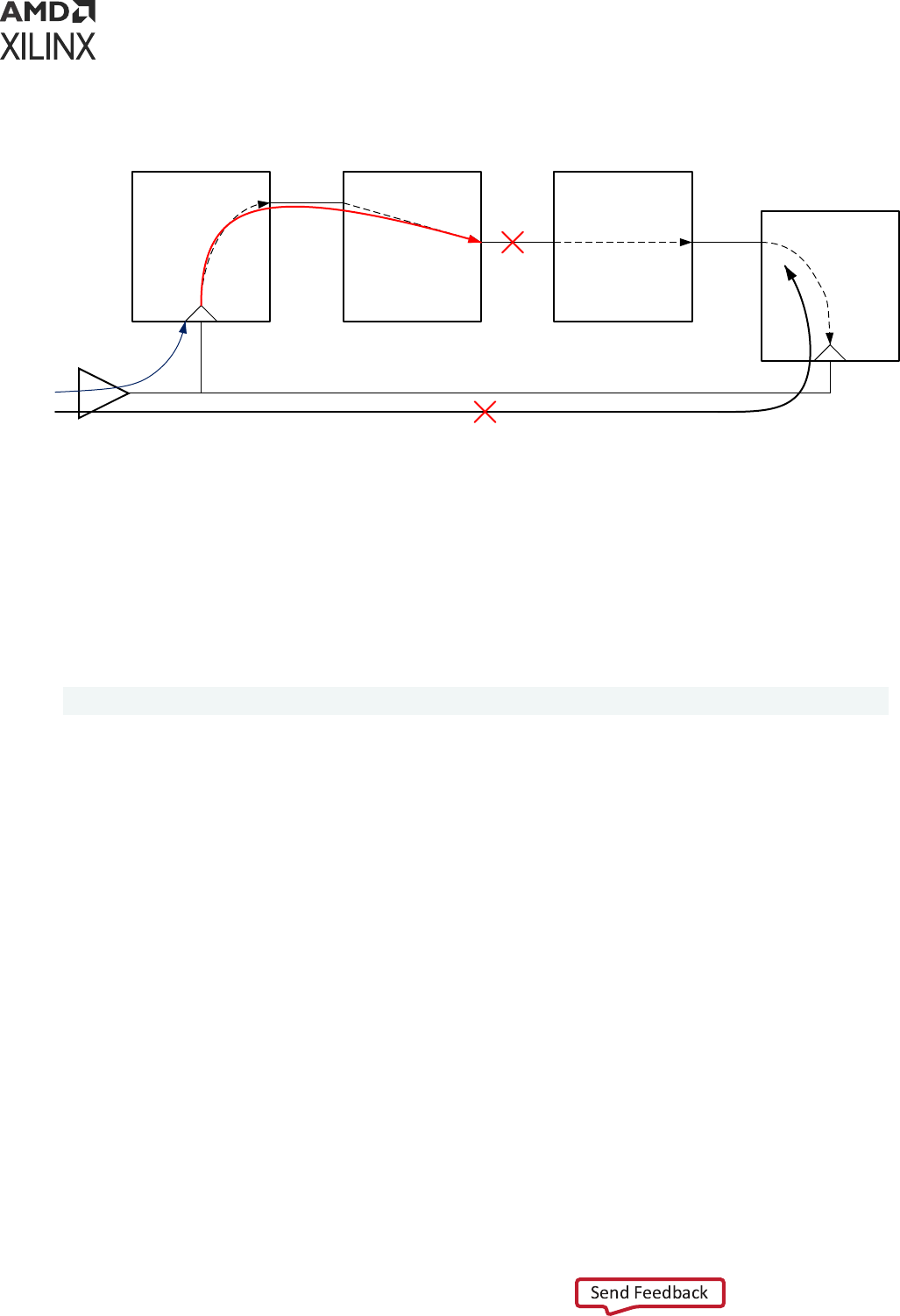

Logically Exclusive Clock Groups with Interaction

The Timing Constraints wizard idenes logically exclusive clocks that have ming paths

between each other elsewhere than just on the logic connected to the shared clock tree. The

following gure shows an example where clkA and clkB have a shared clock tree poron, and

also have a ming path from the shared clock tree to clkA only.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 43

Figure 28: Example of a Design with Logically Exclusive Clocks with Interaction

Because only the clock domain crossing paths of the shared clock tree must be ignored, the

wizard recommends to create generated clocks that are copies of clkA and clkB but that only

exist on the shared clock tree. The clock groups constraint is applied to the generated clocks

only, so that the paths outside the logic of the shared clock tree can sll be normally med. The

following gure illustrates the wizard recommended constraints for the example above.

Figure 29: Recommended Constraints for Logically Exclusive Clocks with Interaction

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 44

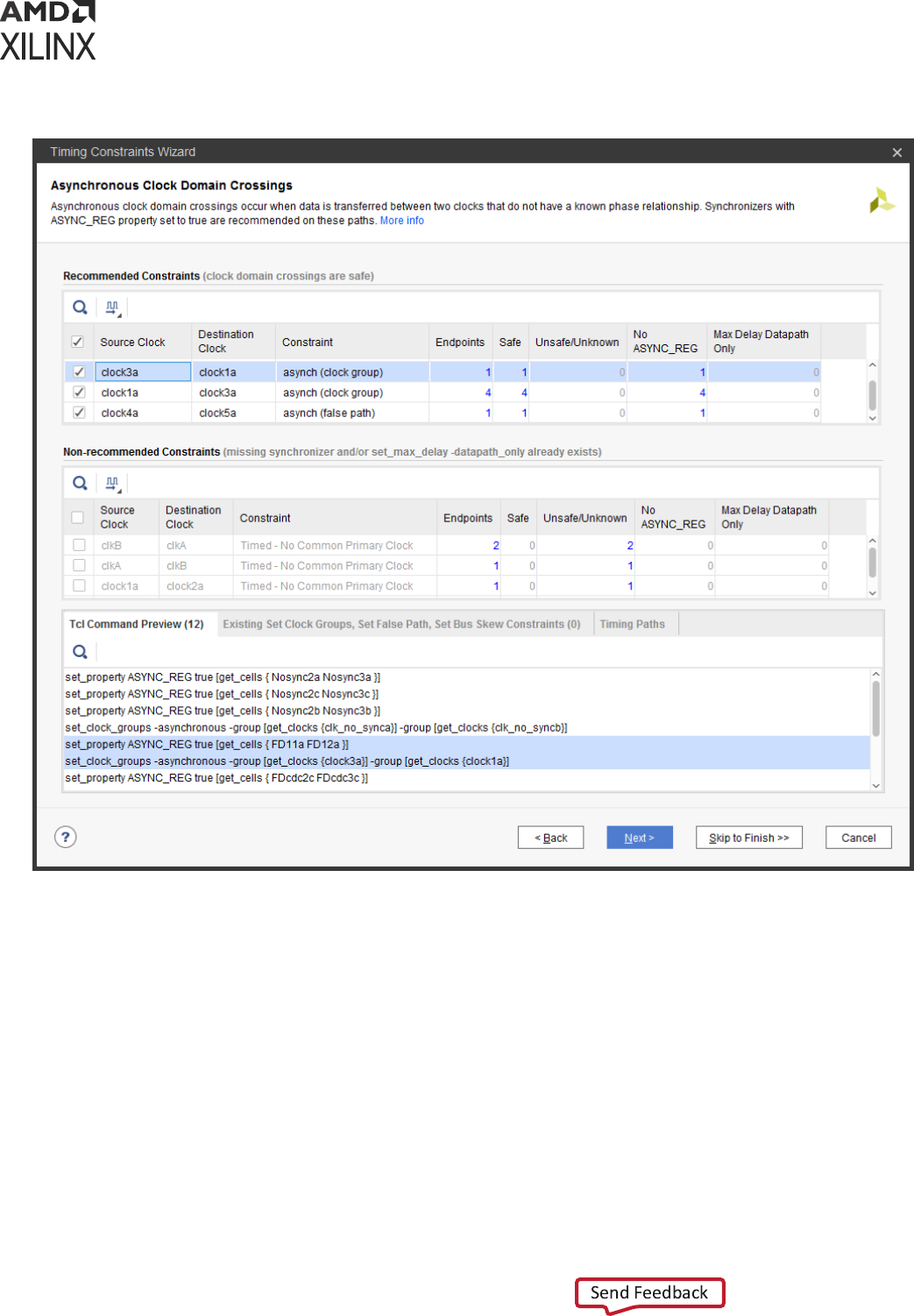

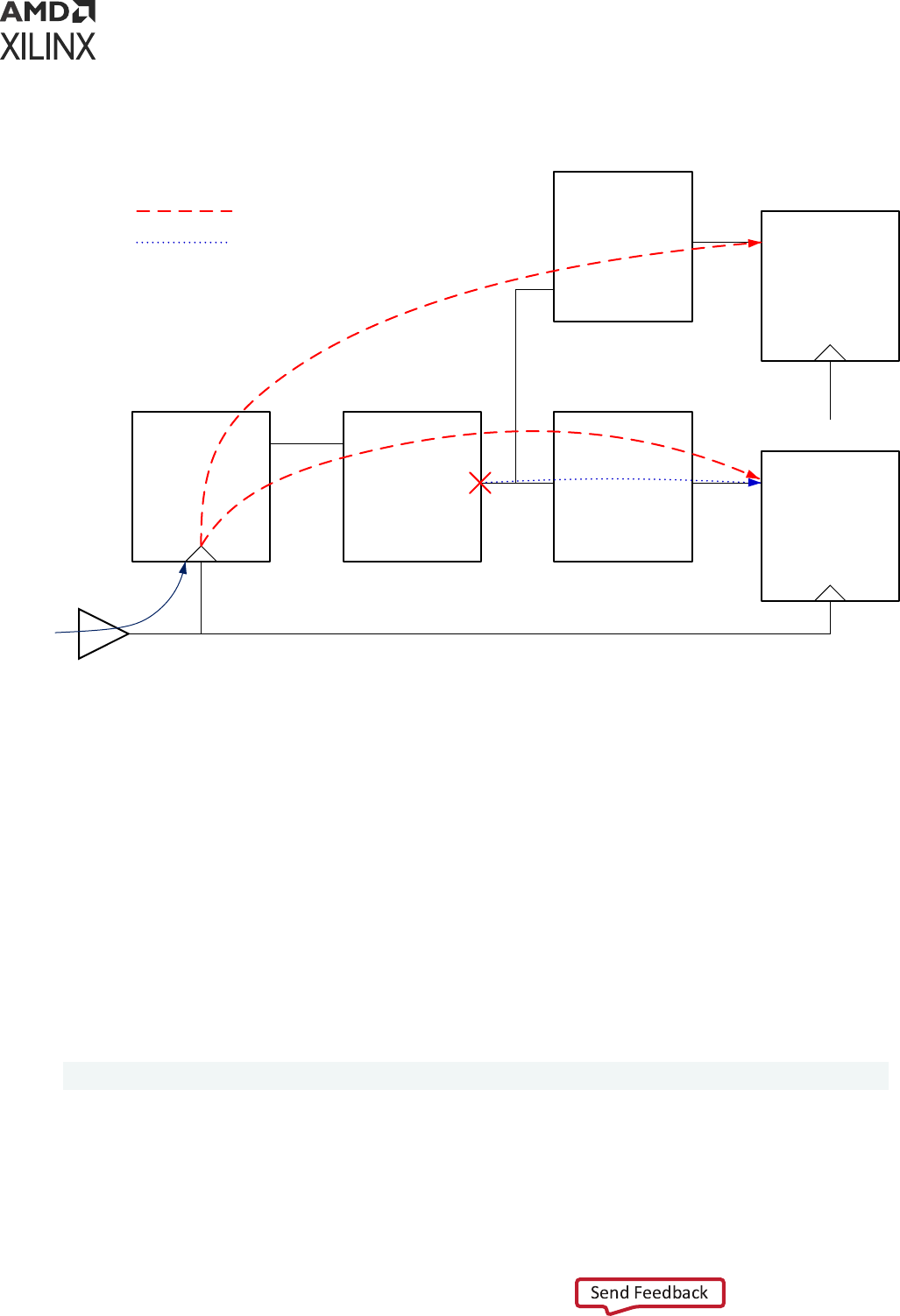

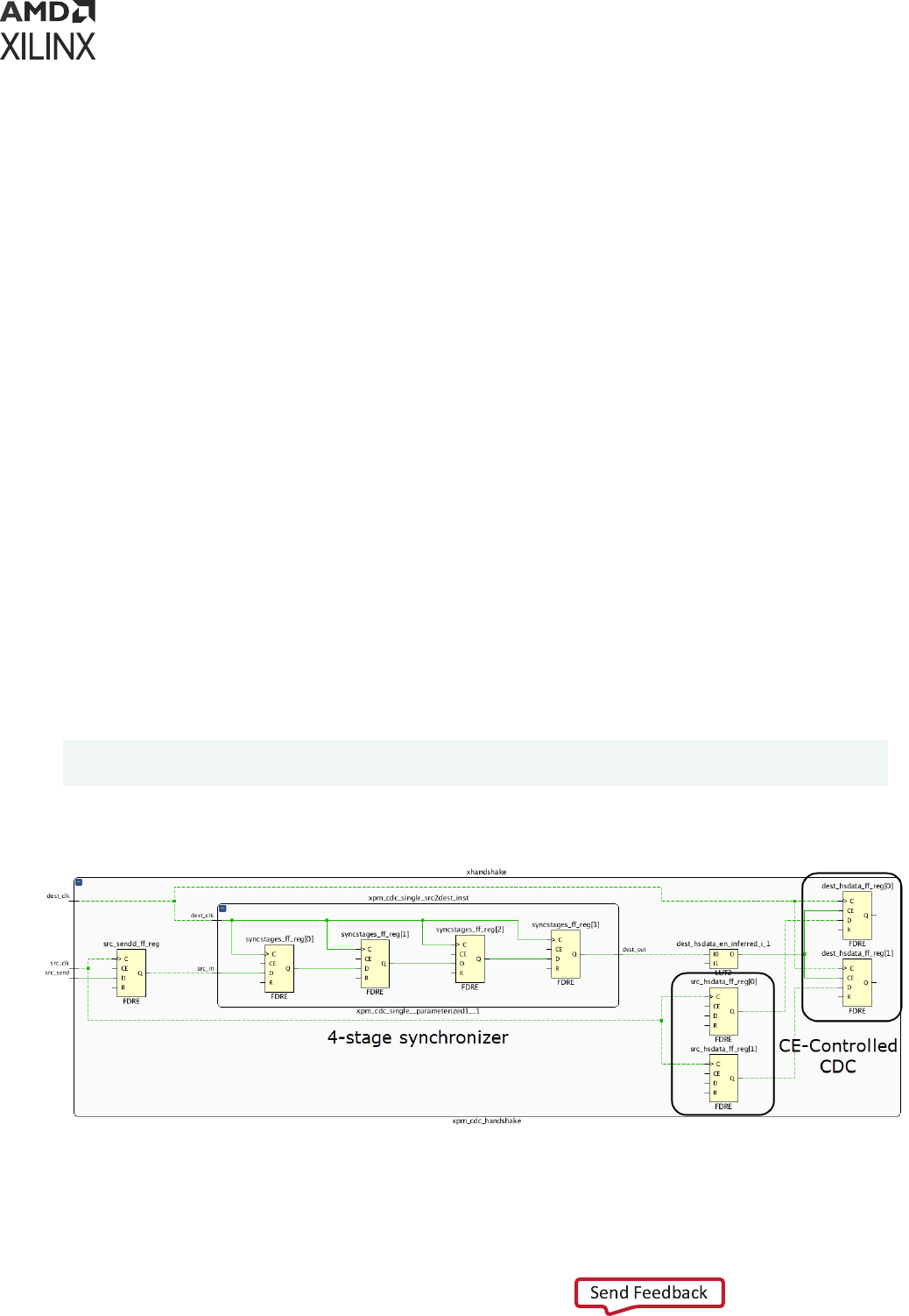

Asynchronous Clock Domain Crossings

The Timing Constraints wizard analyzes the topology of clock domain crossing (CDC) paths

between asynchronous clocks and recommends clock groups or false path constraints whenever

it is safe to do so.

Asynchronous clocks are clocks with no known phase relaonship, which typically happens when

they do not share the same primary clock or do not have a common period. For this reason, slack

computaon on asynchronous CDC paths is not accurate and cannot be trusted. Due to

potenally large skew between asynchronous clocks, the ming quality-of-result can be heavily

impacted and prevent proper ming closure if any of the asynchronous CDC paths is med. You

are responsible for adding ming excepons on these paths, such as set_clock_groups,

set_false_path, or set_max_delay -datapath_only to either completely ignore ming

analysis or just ignore the clock skew and uncertainty. Also, the design must implement proper

CDC circuitry to prevent metastability.

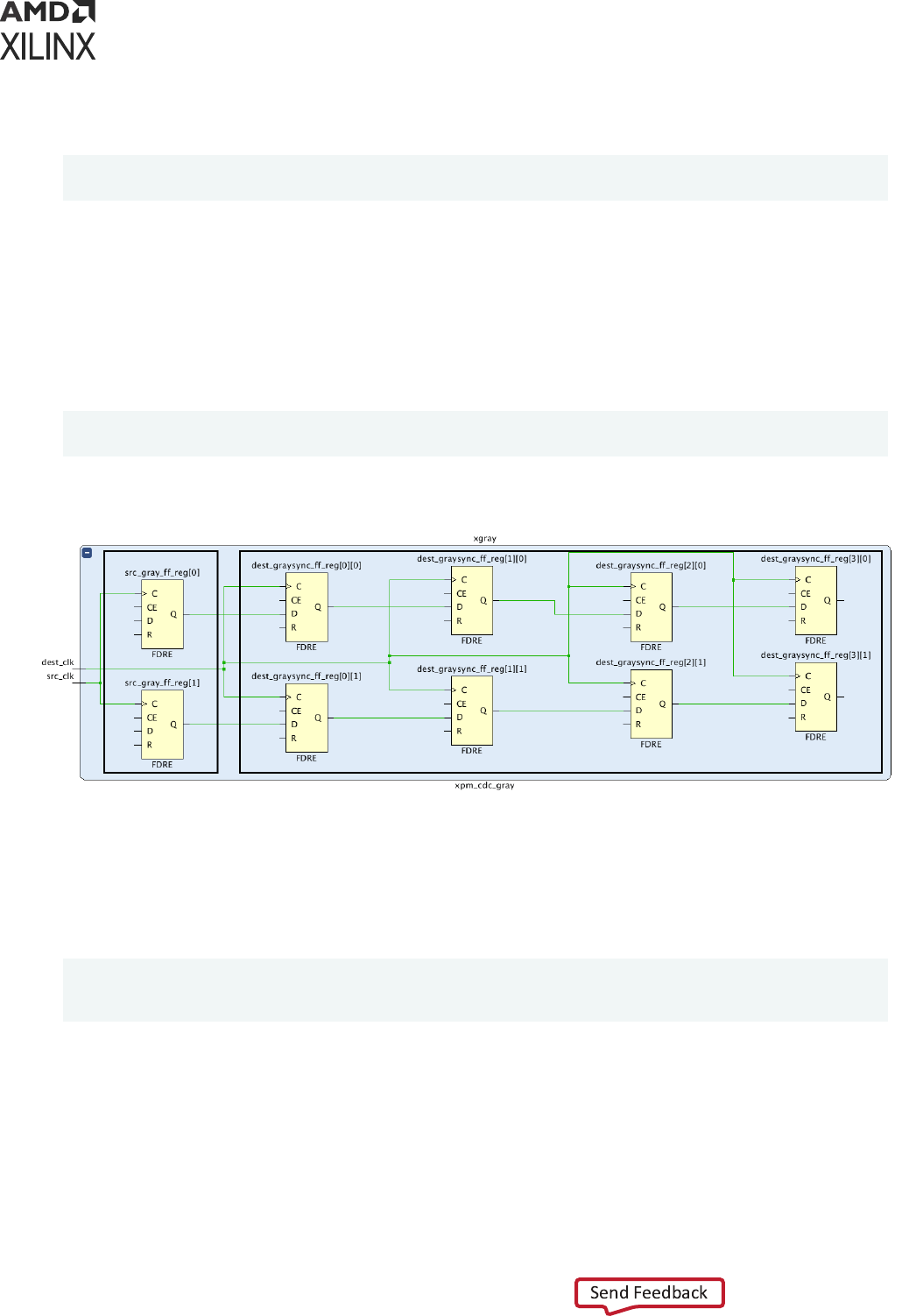

In the Vivado Design Suite, the wizard only idenes ip-op-based synchronizers for

synchronous data and asynchronous reset. For an example of such synchronizers, see the Vivado

Design Suite User Guide: Design Analysis and Closure Techniques (UG906).

The following gure shows an example of the recommended and non-recommended constraints

tables.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 45

Figure 30: Example of Recommended and Non-Recommended Constraints Tables

The columns in both tables display the following informaon:

• Source Clock: This is the clock of the CDC paths start points idened by the wizard.

• Desnaon Clock: This is the clock of the CDC paths endpoints idened by the wizard.

• Constraint: This column shows either the dominant ming excepon or the characteriscs of

the clock relaonship when there is no excepon.

• In the Recommended Constraints table, the wizard ancipates that the constraints will be

created and displays the new constraint:

○ asynch (clock groups) for the cases where it is safe to ignore ming in both direcons, in

which case a set_clock_groups constraint is created

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 46

○ asynch (false path) when it is only safe to ignore the paths in one direcon, in which

case a set_false_path constraint is created

• In the Non-recommended Constraints table, the Timing Constraints wizard displays how

the CDC paths are med before eventually applying a clock group or false path excepon:

○ Timed - No Common Primary Clock

○ Timed - No Common Period

○ MaxDelay DataPath for the case where at least 1 path is covered by a set_max_delay

-datapath_only constraint and all other paths are covered by false path constraints

• Endpoints: The number of CDC path endpoints idened by the wizard.

• Synchronized (with ASYNC_REG): The number of endpoints properly synchronized, with the

ASYNC_REG property set to true on all synchronizer ip-ops.

• Synchronizer without ASYNC_REG: The number of synchronizers where at least one ip-op

does not have the ASYNC_REG property set to true.

• Unknown: The number of CDC path endpoints where the wizard did not nd a synchronizer.

• Max Delay Datapath Only: The number of CDC path endpoints that are constrained with a

set_max_delay -datapath_only constraint.

The table entries contain cross-probing links whenever applicable. When you click on a number,

the corresponding CDC paths are listed in the Paths tab at the boom of the window. You can

select one or several CDC paths and click on the Schemac (F4) buon to display the logic of the

path(s) in the main Vivado IDE window.

Recommended Asynchronous Clock Groups Constraints

The Timing Constraints wizard recommends a set_clock_groups -asynchronous

constraint between two clocks when the following condions are present:

• All paths have synchronizers in both direcons.

• No path is covered by a set_max_delay -datapath_only in either direcon

(set_clock_groups has higher precedence and overrides any exisng set_max_delay).

Non-Recommended Asynchronous Clock Groups Constraints

The Timing Constraints wizard provides a table with constraints that are not enabled by default

because they are not recommended for one of the following reasons:

• At least one path is missing a synchronizer in either direcon.

• At least one path is covered by set_max_delay -datapath_only in either direcon.

You can decide to acvate any of these constraints when working on an early version of the

design, and then revisit the CDC paths and their constraints later when nalizing your design.

Chapter 2: Constraints Methodology

UG903 (v2022.1) June 1, 2022 www.xilinx.com

Using Constraints 47

CDC Synchronizers and ASYNC_REG Property

Xilinx recommends that all synchronizer ip-ops have their ASYNC_REG property set to true in

order to preserve the synchronizer cells through any logic opmizaon during synthesis and

implementaon, and to opmize their placement for best Mean Time Between Failures (MTBF)

stascs. For any clock group constraints that are enabled in both tables (either by default or by

the user), the wizard sets to true any missing ASYNC_REG property.

Refer to the Vivado Design Suite Properes Reference Guide (UG912) for detailed informaon

about the ASYNC_REG property.

Completing the CDC Analysis and Constraints

The Timing Constraints wizard does not recognize some valid CDC topologies that are not based

on simple synchronizers. The report_cdc command provides a powerful and more comprehensive

view of the CDC paths that need structural correcon in order to become safe. Refer to the

Vivado Design Suite User Guide: Design Analysis and Closure Techniques (UG906) for detailed

informaon about report_cdc.

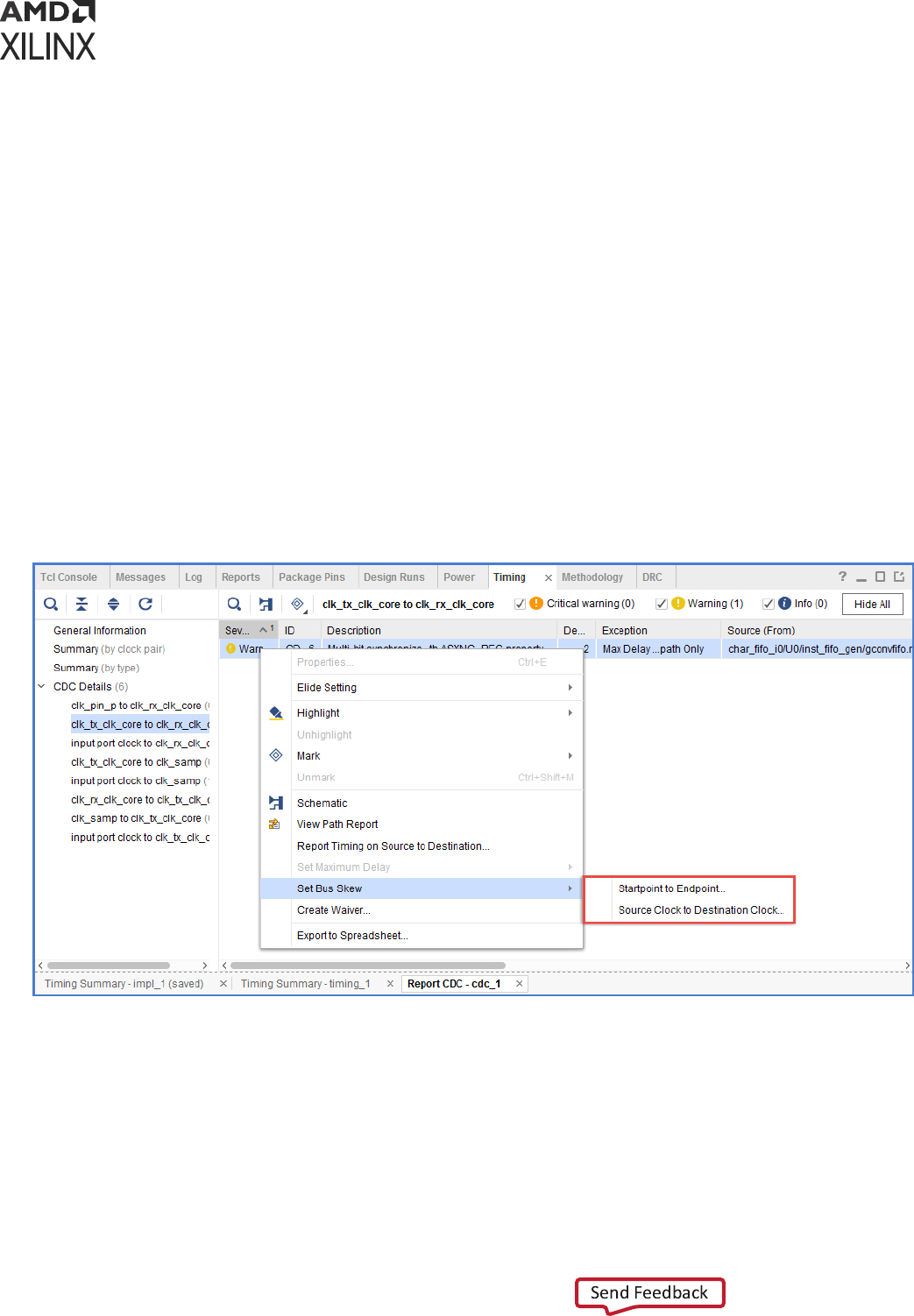

For the cases where the wizard does not recommend a constraint due to the presence of some

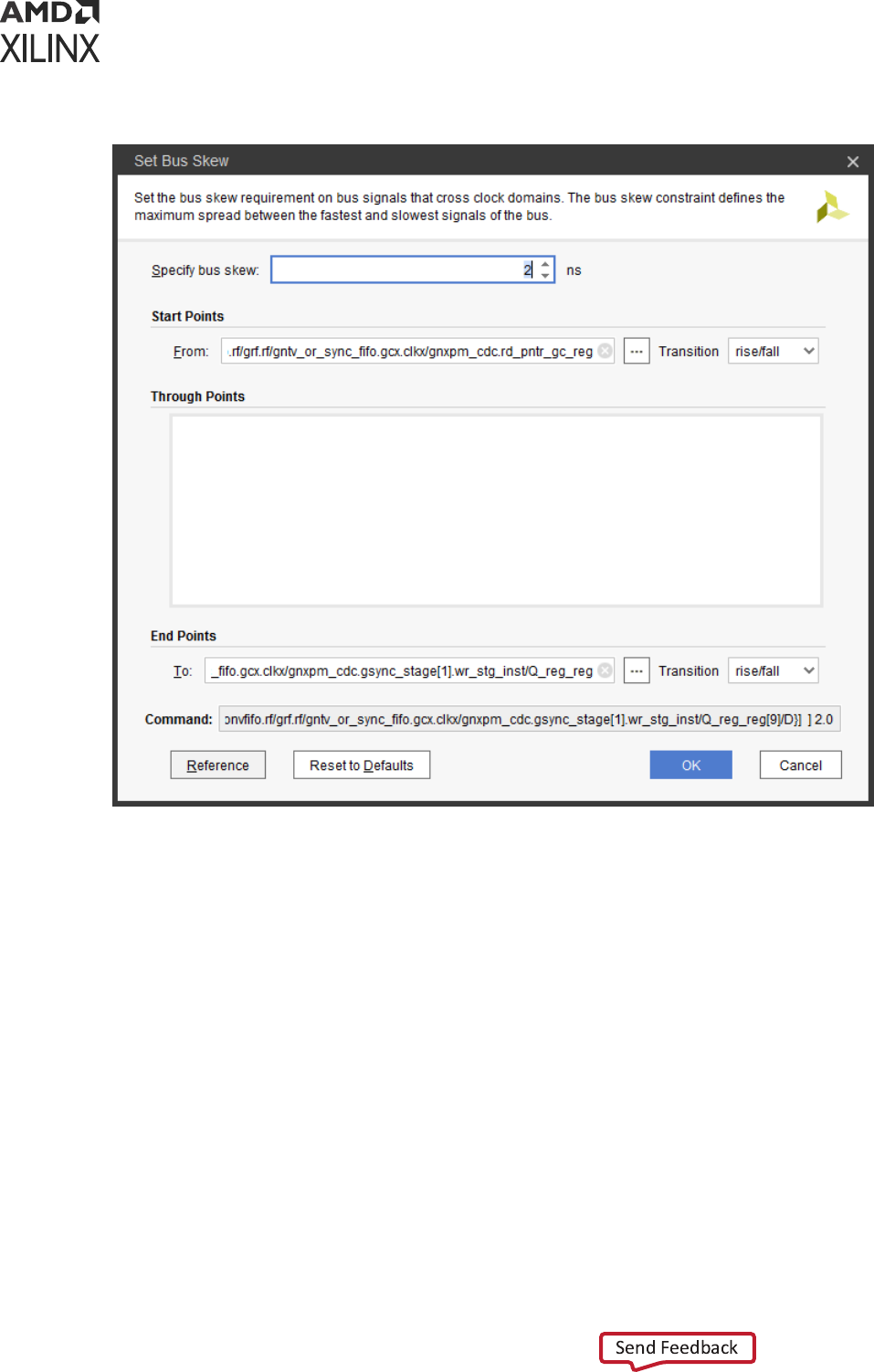

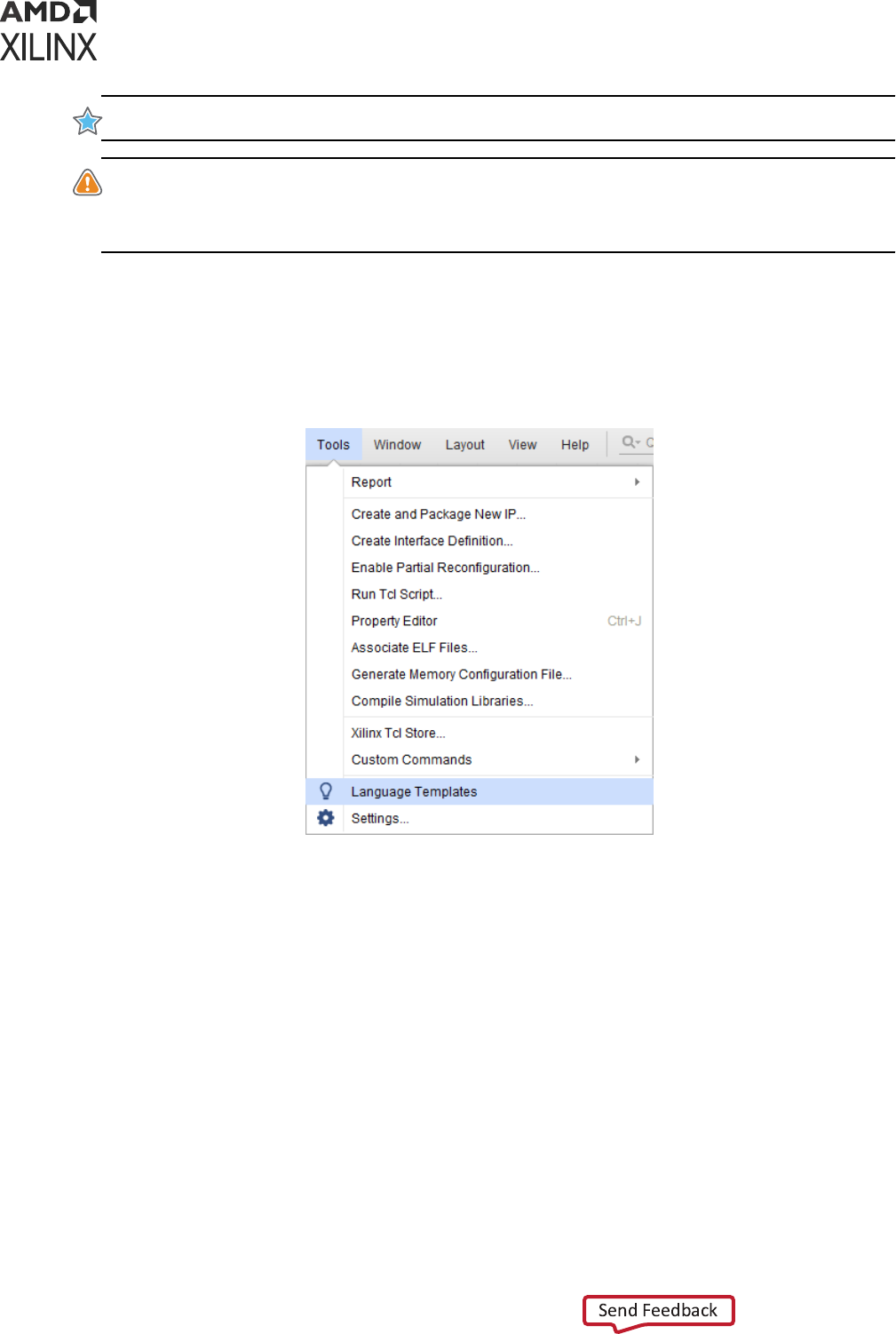

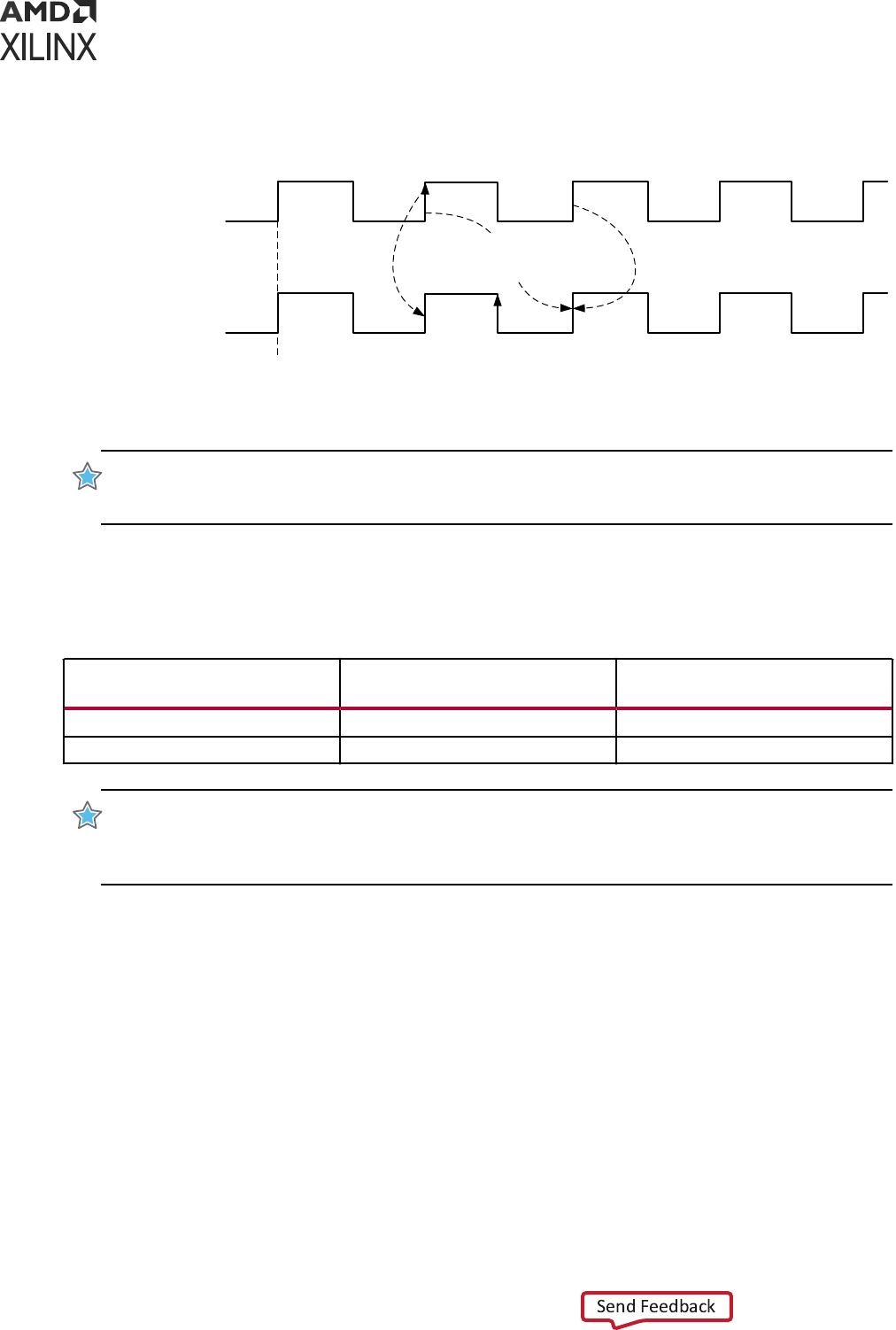

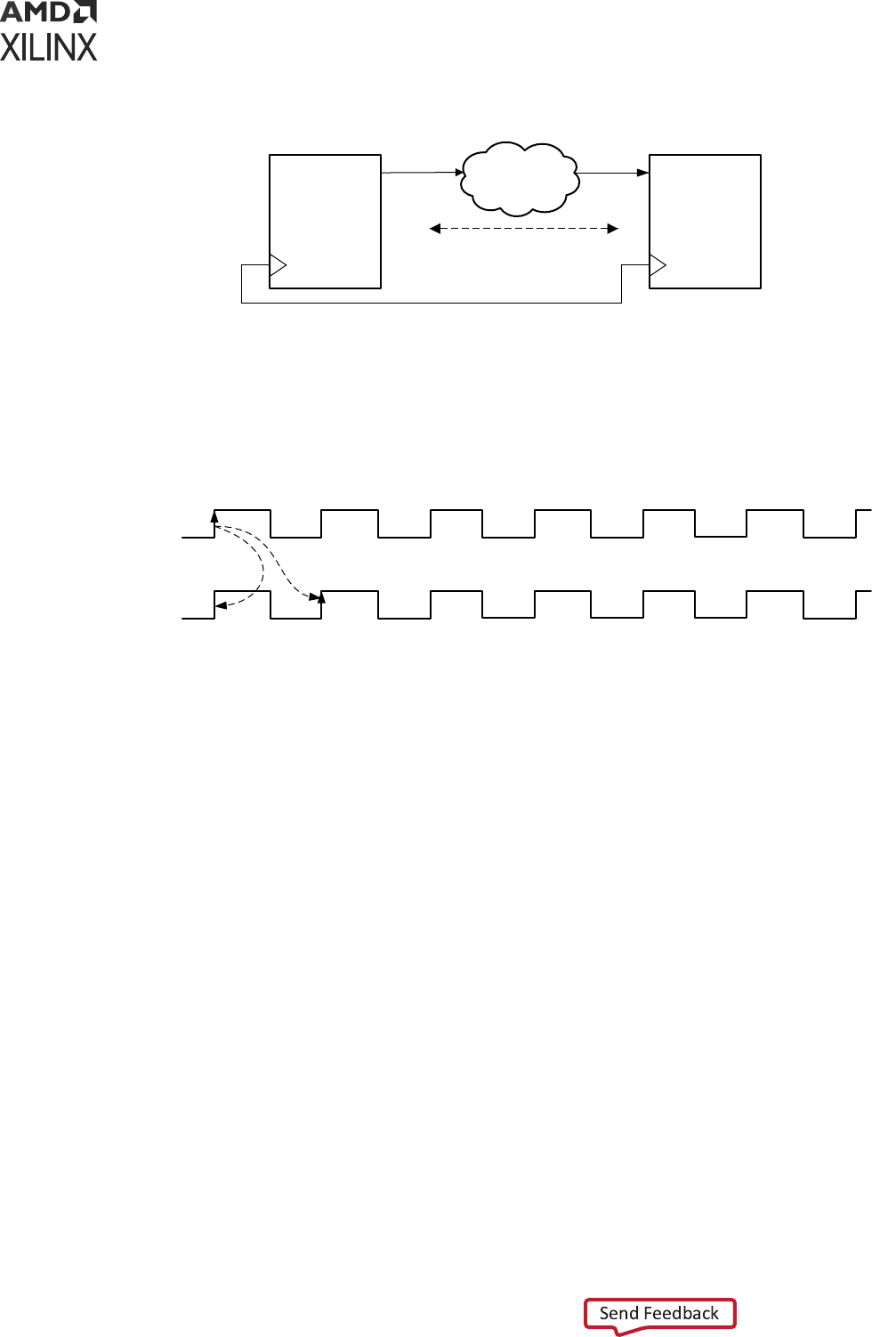

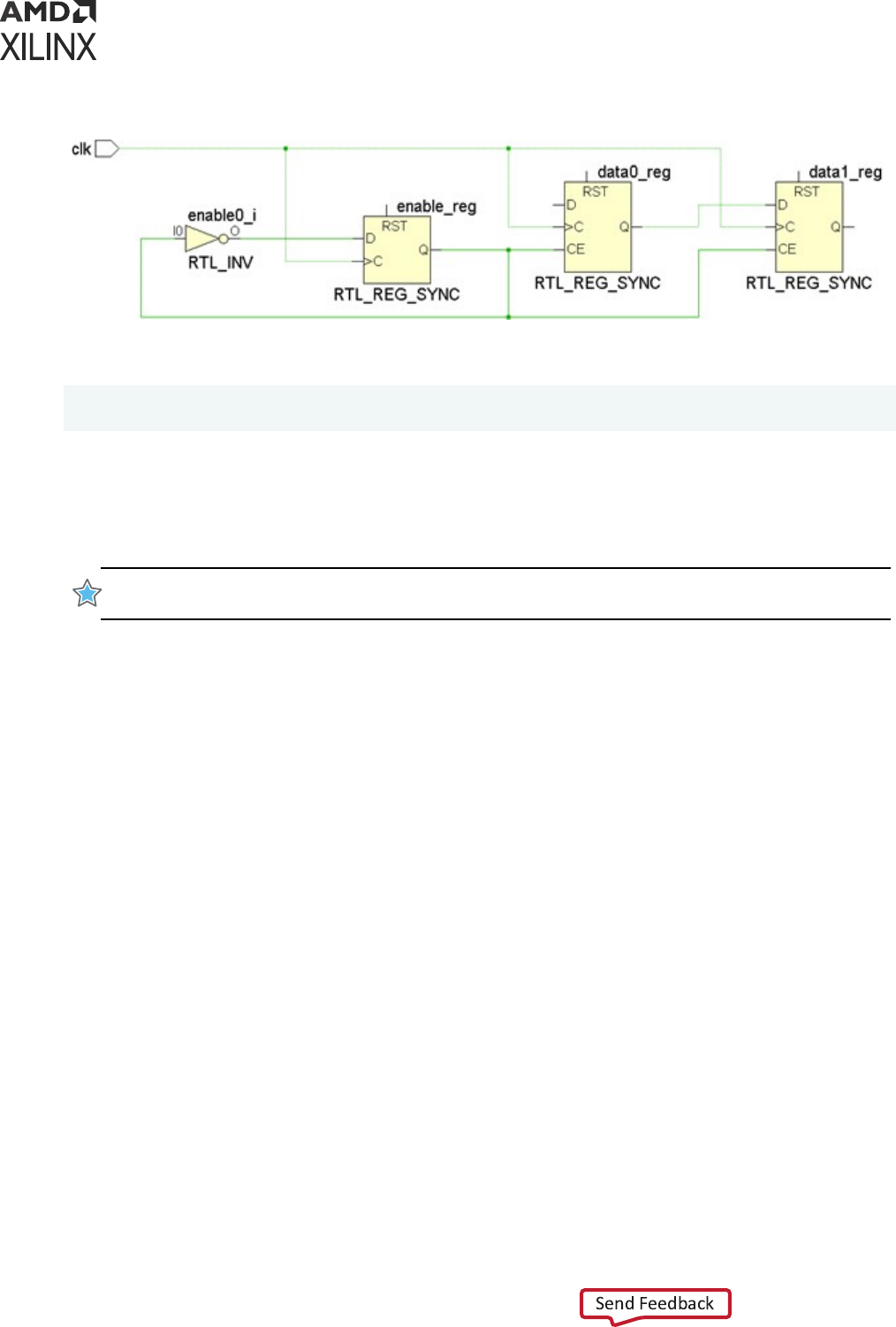

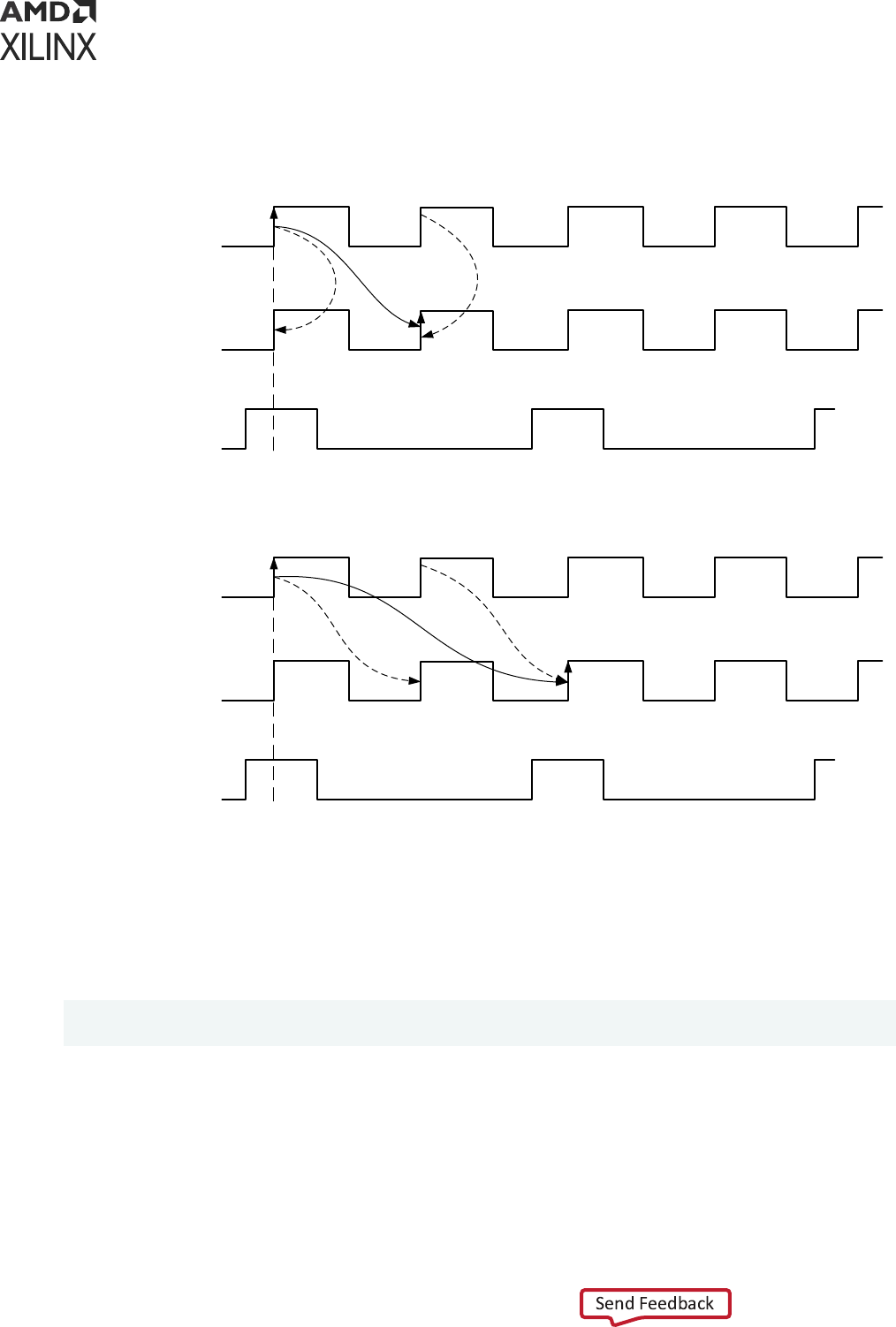

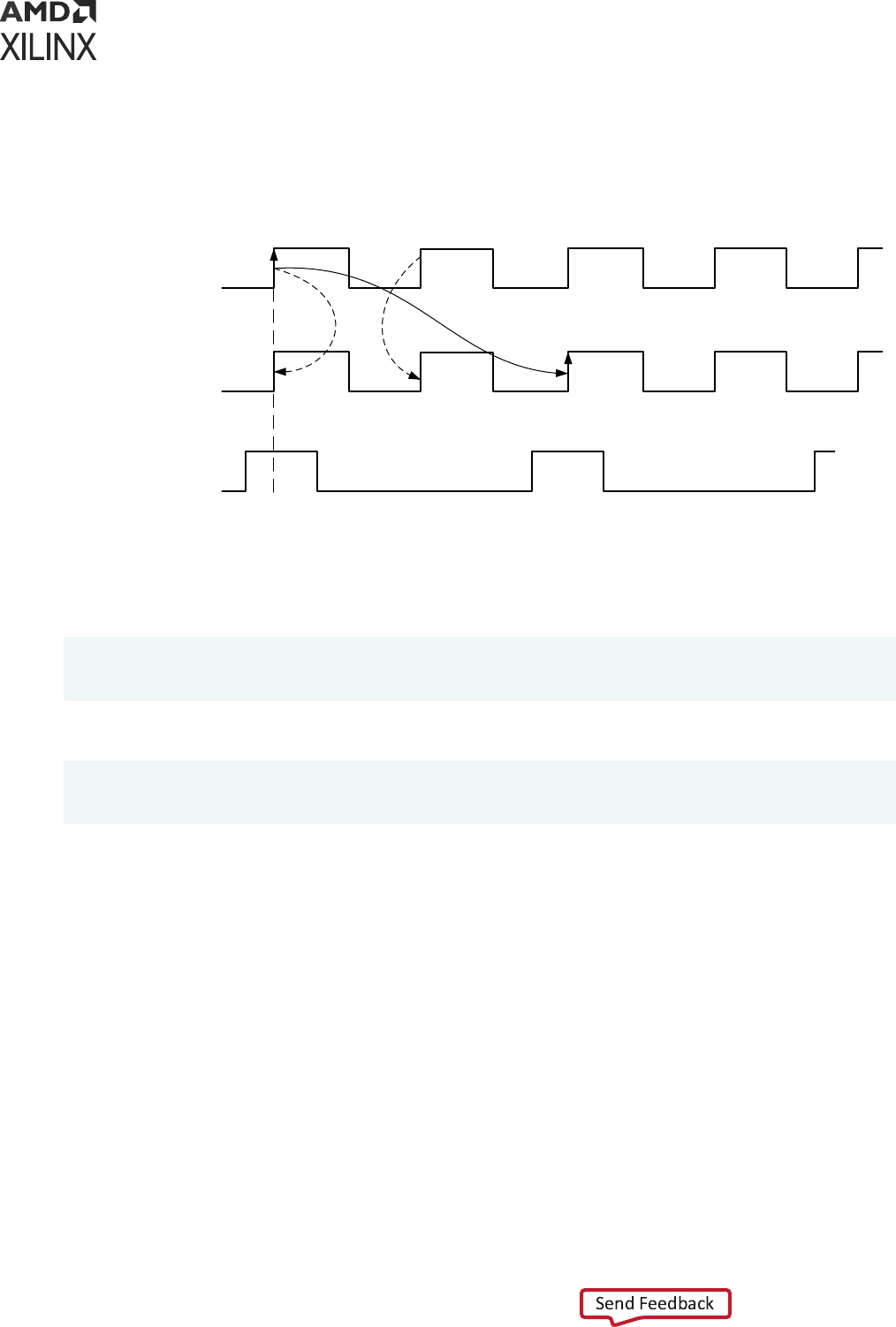

set_max_delay -datapath_only, the other CDC paths that are normally med must be